Z-direction steel rolling production line for high-rise building

A technology for high-rise buildings and production lines, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of accelerating lubricant consumption, increasing hot rolling operation steps, etc., to ensure the effect of quality and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

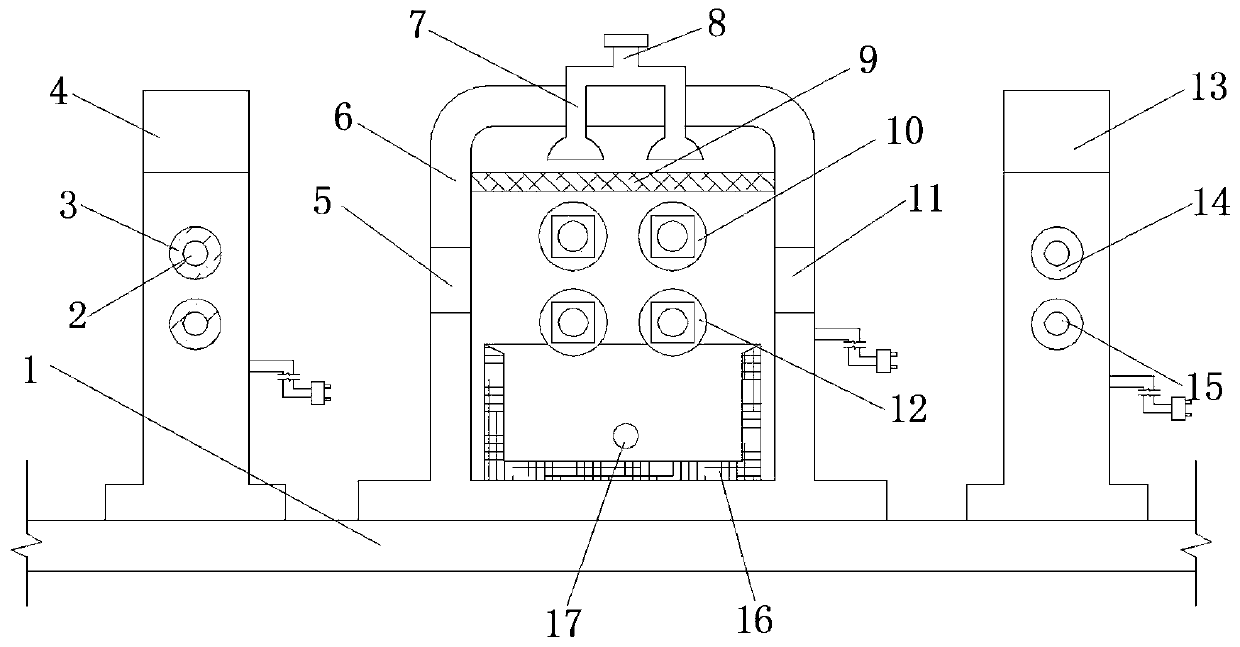

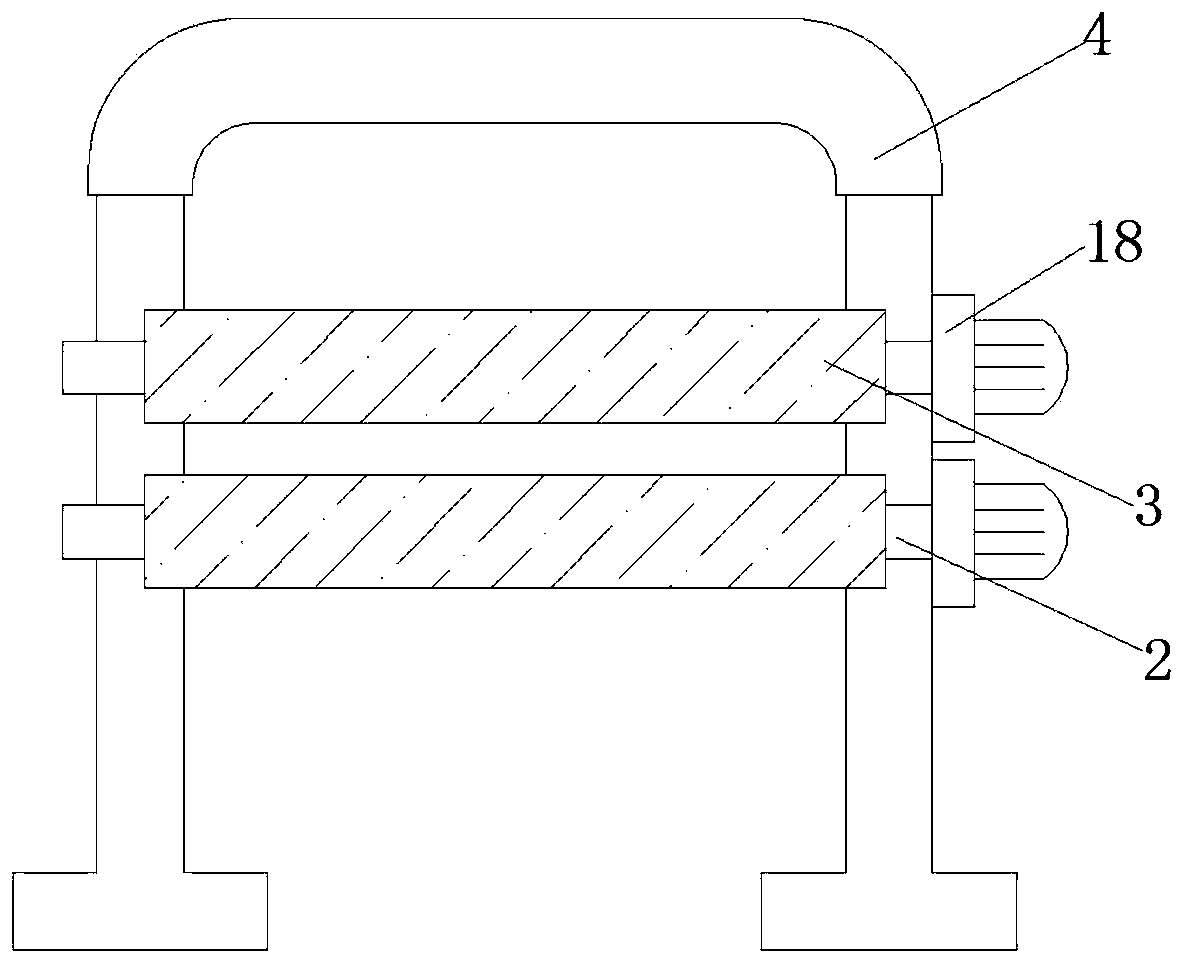

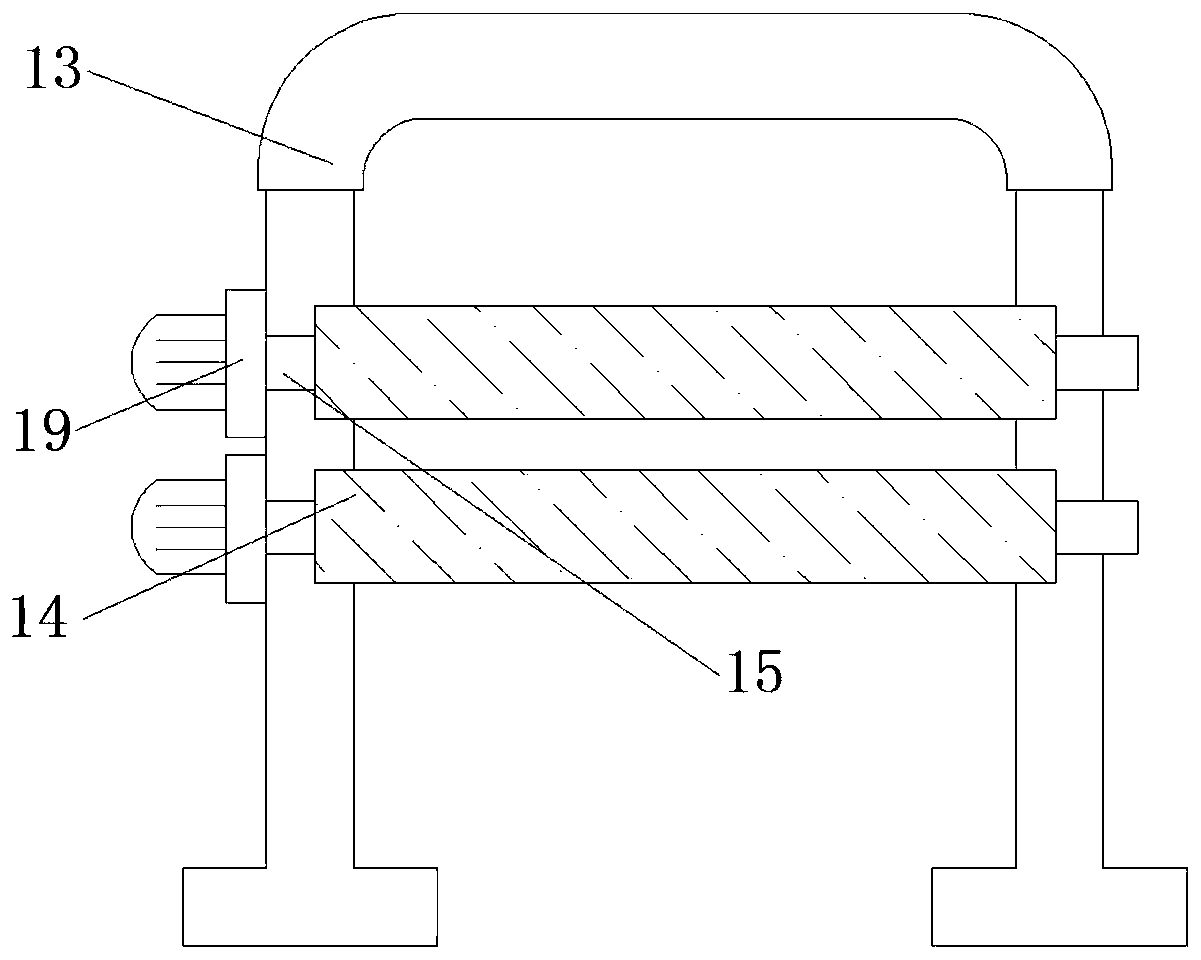

[0023] Example: refer to Figure 1-4 , a Z-direction steel rolling production line for high-rise buildings, the upper end of the base 1 is provided with a first fixed frame 4, a second fixed frame 13 and a hot rolling mill 6, and the inside of the second fixed frame 13 is provided with a pair of Lead-in roller 14, one end screw of second fixed frame 13 is fixed with two second motors 19, and the output end of second motor 19 is connected with the first rotating rod 2 by coupling, and the first rotating rod 2 is fixedly connected in importing Roll 14 inside.

[0024] Specifically, when processing Z-direction steel, by controlling the start-up of the second motor 19, the second motor 19 drives the lead-in roller 14 to make a circular motion, so that the pair of lead-in rollers 14 arranged up and down in the first fixed frame 4 , play the role of guide conveying to the steel plate, make the steel plate convey to the position side of the hot rolling mill 6.

[0025] Wherein, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com