Hot metal pouring system of hot metal bottle

A technology for molten iron tank and molten iron, which is used in casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of large iron turning dust, easy splashing of molten iron, and inability to collect, achieves high iron connection efficiency, and is conducive to collecting smoke and dust. , Reduce the effect of molten iron splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

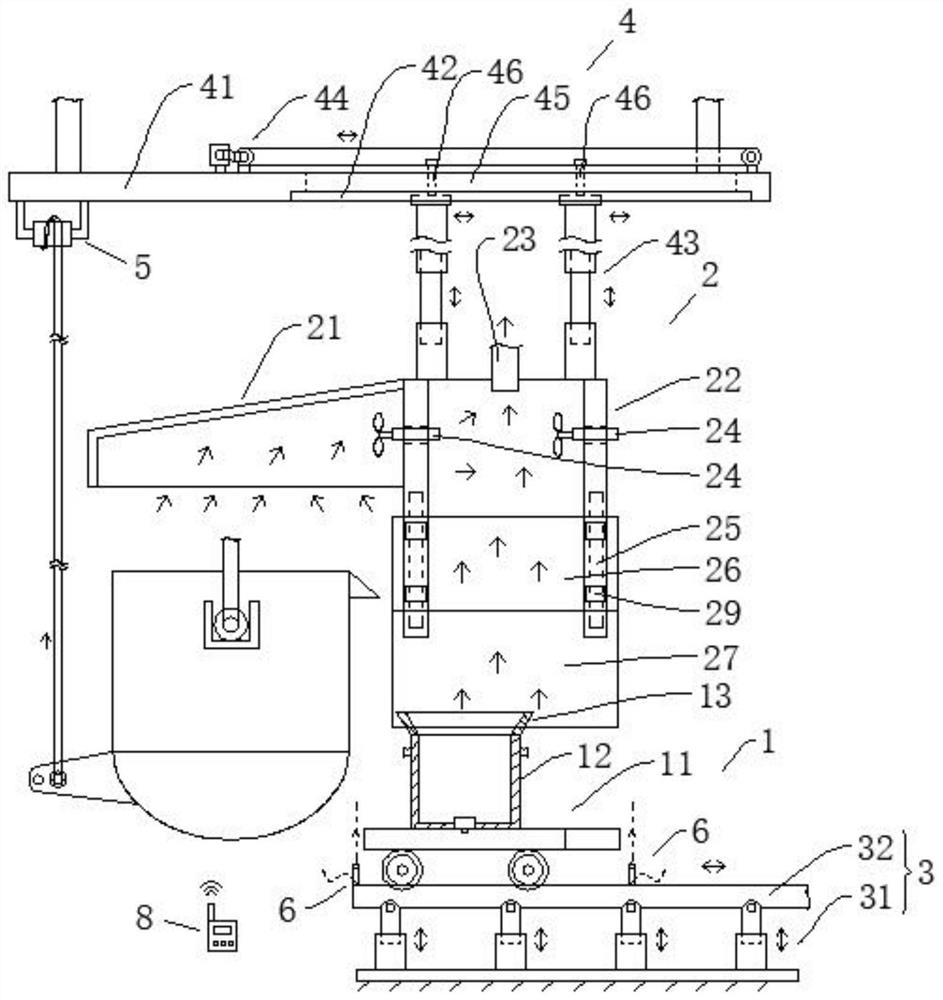

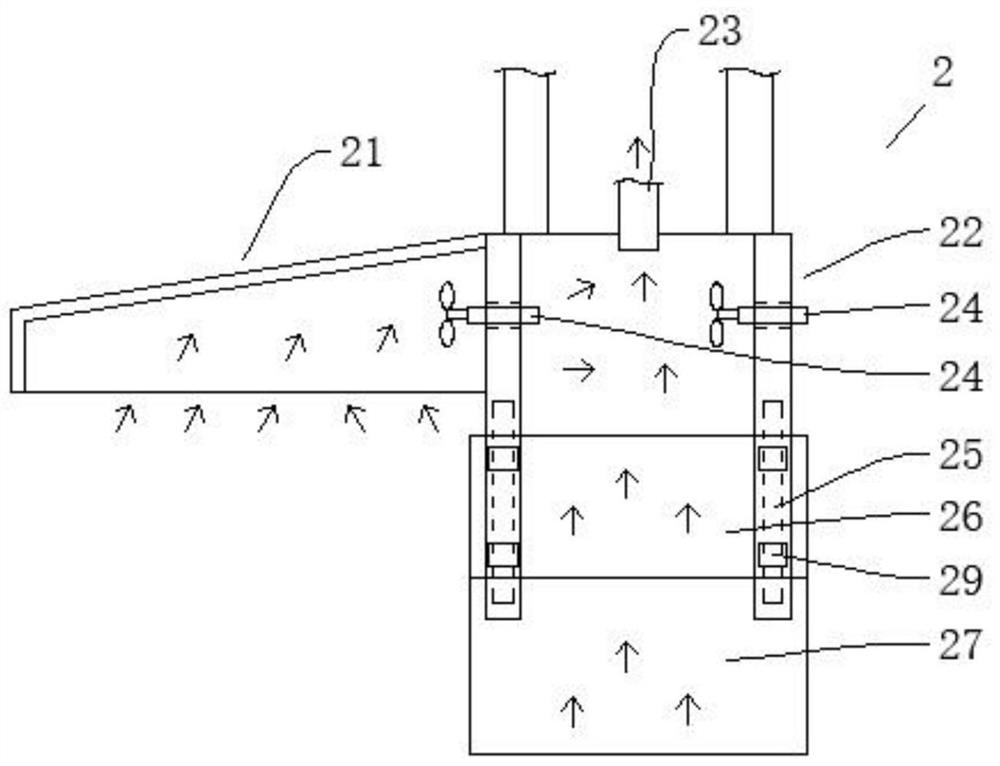

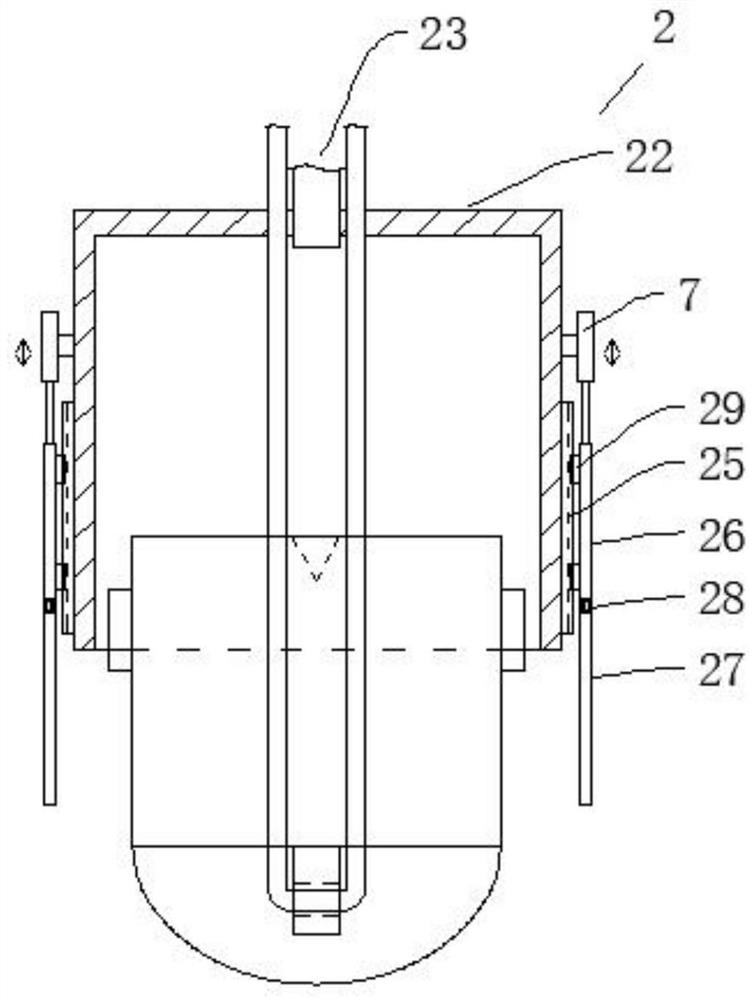

[0025] Please also refer to Figure 1 to Figure 6 , a kind of ladle iron tipping system provided by the present invention will now be described. The iron ladle tank turning system includes an iron assembly 1, a dust removal mechanism 2 and a lifting mechanism 3. The iron assembly 1 is movably arranged under the ladle, and the iron assembly 1 can move toward and receive the iron ladle. The molten iron poured out from the molten iron tank; the dust removal mechanism 2 is buckled on the top of the molten iron tank to collect the smoke and dust generated during the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap