Rotary reamer for cleaning slag iron at tuyere of iron-making blast furnace and device for cleaning slag iron at tuyere of iron-making blast furnace

An iron-making blast furnace and tuyere technology, which is applied in the field of rotary reamers and devices, can solve the problems of slag hanging or slag filling in the tuyere, high cleaning cost, low cleaning efficiency, etc., so as to avoid danger, high cleaning cost and low cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0057] Such as Figure 4 As shown, the telescopic cylinder 300 includes a first cylinder 301 and a second cylinder 302, and the two ends of the driver are respectively connected to the first cylinder 301 and the second cylinder 302; in the initial state, the driver can Shrunken in the first cylinder 301 ; in an extended state, the driver can at least partly be exposed outside the first cylinder 301 .

Embodiment approach 2

[0059] Such as Figure 5 As shown, the telescopic cylinder 300 includes a first cylinder 301 and a second cylinder 302, and the two ends of the driving member are respectively connected to the first cylinder 301 and the second cylinder 302; in the initial state, the second cylinder 302 It can be shrunk in the first cylinder 301 ; in the extended state, the second cylinder 302 can at least partly be exposed outside the first cylinder 301 .

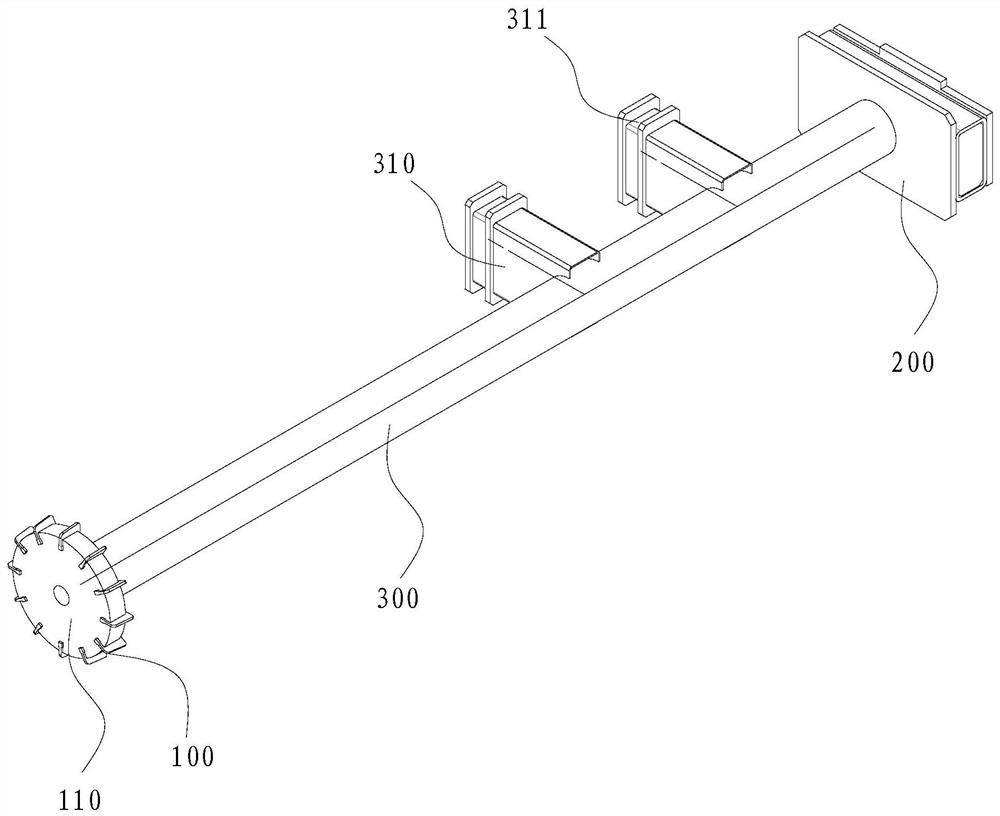

[0060] Additionally, if Figure 6 and Figure 7 As shown, the present invention also provides a device for cleaning slag and iron at the tuyere of the ironmaking blast furnace, the device includes a rotary reamer for cleaning the slag and iron at the tuyere of the ironmaking blast furnace, and a mobile car 400 with a gantry 410; The bottom of the mobile vehicle 400 is provided with a first guide part 401, and the bottom of the gantry frame 410 is correspondingly provided with a first sliding part (not shown in the figure), and the first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com