A kind of copper ion doped polychromatic fluorescent glass and its preparation method and application

A technology of fluorescent glass and copper ions, which is applied in glass manufacturing equipment, glass furnace equipment, chemical instruments and methods, and can solve problems such as limited application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

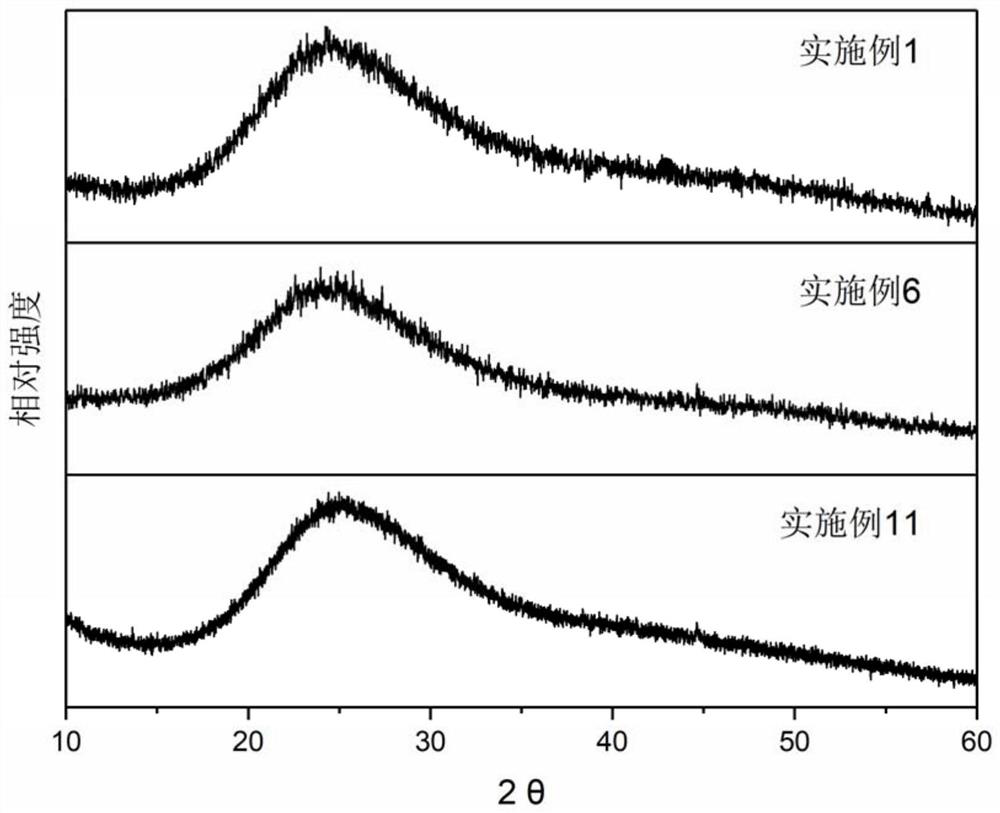

Embodiment 1

[0045] This embodiment provides a multicolor fluorescent glass doped with copper ions, the chemical formula of the fluorescent glass is aP 2 o 5 -bSiO 2 -cZnO-dCs 2 CO 3 -eNaCl-fCuCl, its preparation method comprises the steps:

[0046] S1. Weigh P 2 o 5 , SiO 2 , ZnO, Cs 2 CO 3 , NaCl, CuCl and reducing agent, and thoroughly grind and mix for 0.5h;

[0047] S2. Under a reducing atmosphere, melt at 1100°C for 30 minutes;

[0048]S3. Pour into a preheated mold, anneal at 350°C for 2 hours, cool, cut, and polish to obtain copper ion-doped multicolor fluorescent glass. See Table 1 for the specific formula.

Embodiment 2~10

[0050] The embodiment provides a series of copper ion doped fluorescent glasses, the chemical formula of which is aP 2 o 5 -bSiO 2 -cZnO-dCs 2 CO 3 -eNaCl-fCuCl, the preparation method is the same as in Example 1, and the specific formula is shown in Table 1.

[0051] The formula of table 1 embodiment 1~10

[0052]

Embodiment 11~17

[0054] The embodiment provides a series of copper ion doped fluorescent glasses, the chemical formula of which is aP 2 o 5 -bSiO 2 -cZnO-dCs 2 CO 3 -eNaCl-fCuCl, the preparation method is the same as in Example 1, and the specific formula is shown in Table 2.

[0055] The formula of table 2 embodiment 11~17

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com