Fluorine-silicon composite visible-light-catalyzed antibacterial antifouling coating material and preparation method thereof

An anti-fouling coating and visible light technology, applied in anti-fouling/underwater coatings, coatings, devices for coating liquids on surfaces, etc., can solve the problems of coating hardness not meeting the requirements, substrate detachment, and low coating surface Energy and other issues, to achieve the effect of strength improvement, surface biofouling prevention, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

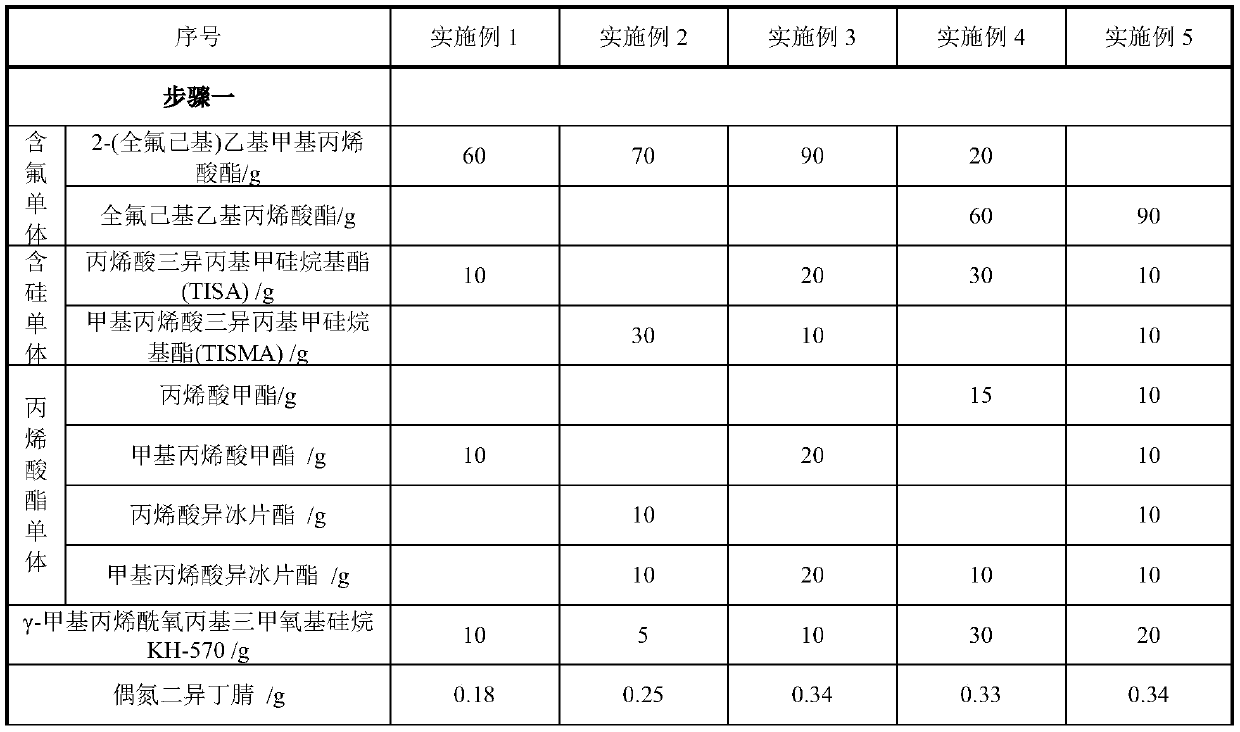

[0036] Below in conjunction with specific embodiment and comparative example the invention is described in further detail. The examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

[0037] The preparation and application method of the fluorine-silicon composite visible light catalyzed antibacterial antifouling coating comprises the following steps:

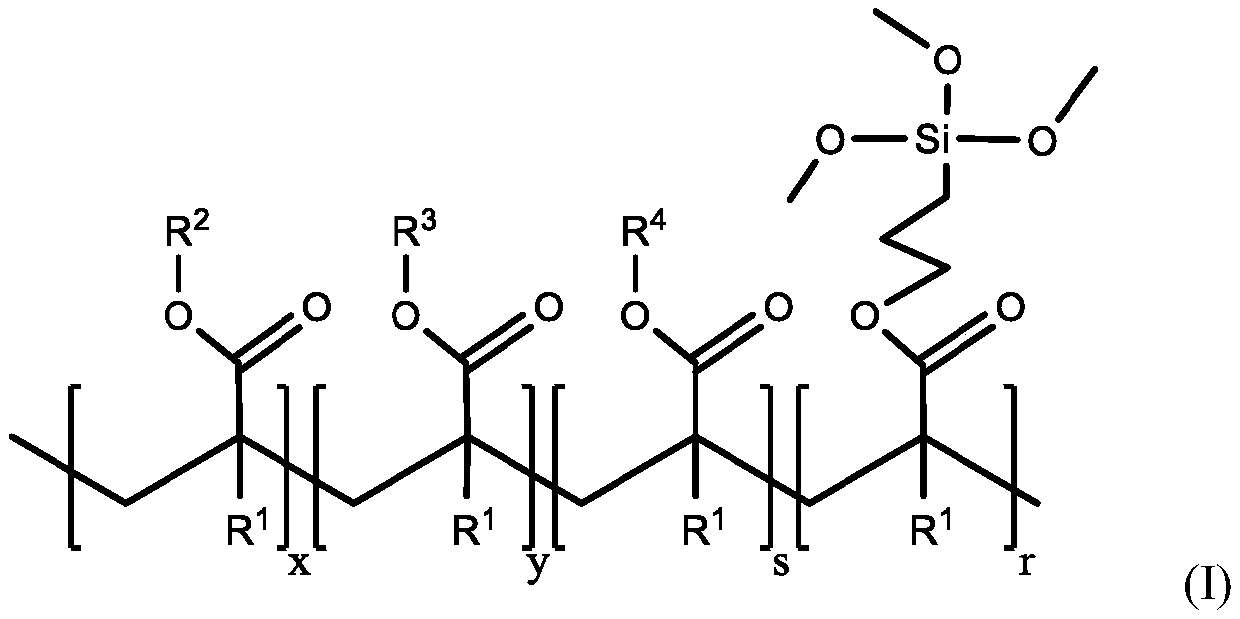

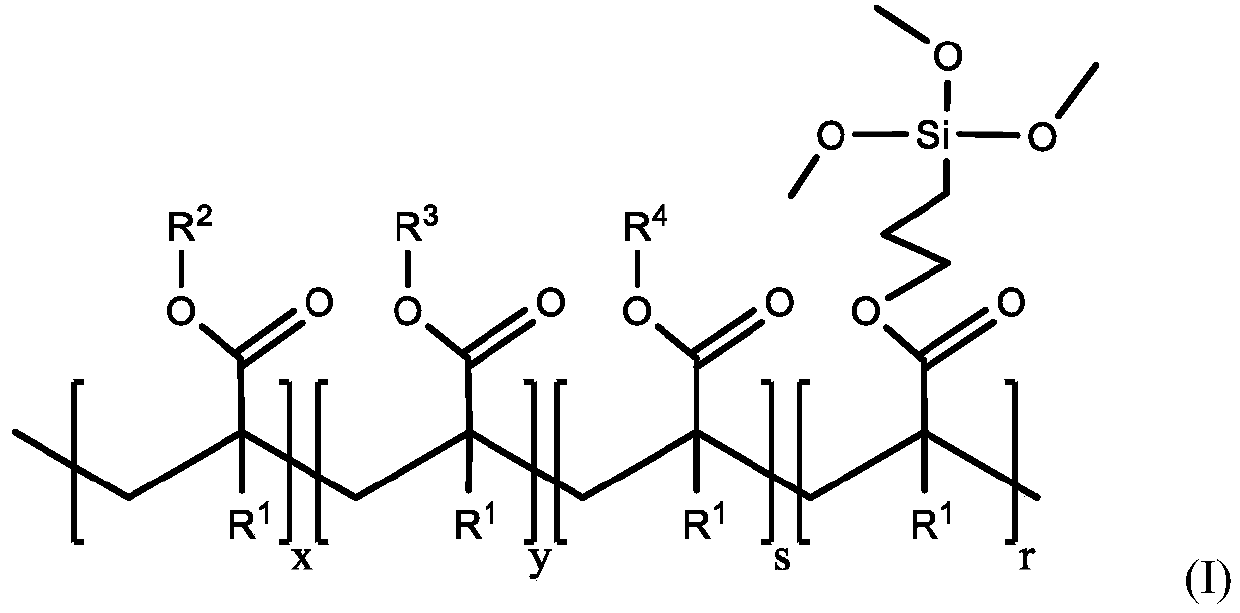

[0038] step one:

[0039] Take 60-90 parts by weight of fluorine-containing (meth)acrylate monomers, 10-30 parts by weight of silicon-containing (meth)acrylate monomers, 10-40 parts by weight of acrylate monomers and 5-30 parts by weight Reactive silane coupling agent in parts by weight, mixed evenly; then add azobisisobutyronitrile as an initiator, the initiator accounts for 0.2% of the total weight of all monomers; then add hydrofluoric acid equal to the total weight of all monomers Ether, react at 70°C for 5-10 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com