A kind of fireproof coating with photocatalytic performance and preparation method thereof

A technology of fireproof coatings and photocatalysis, applied in fireproof coatings, coatings, etc., can solve the problems of high recombination rate of electrons and holes, low photocatalytic activity, low light utilization rate, etc., to improve anti-aging performance, photocatalytic Low activity and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

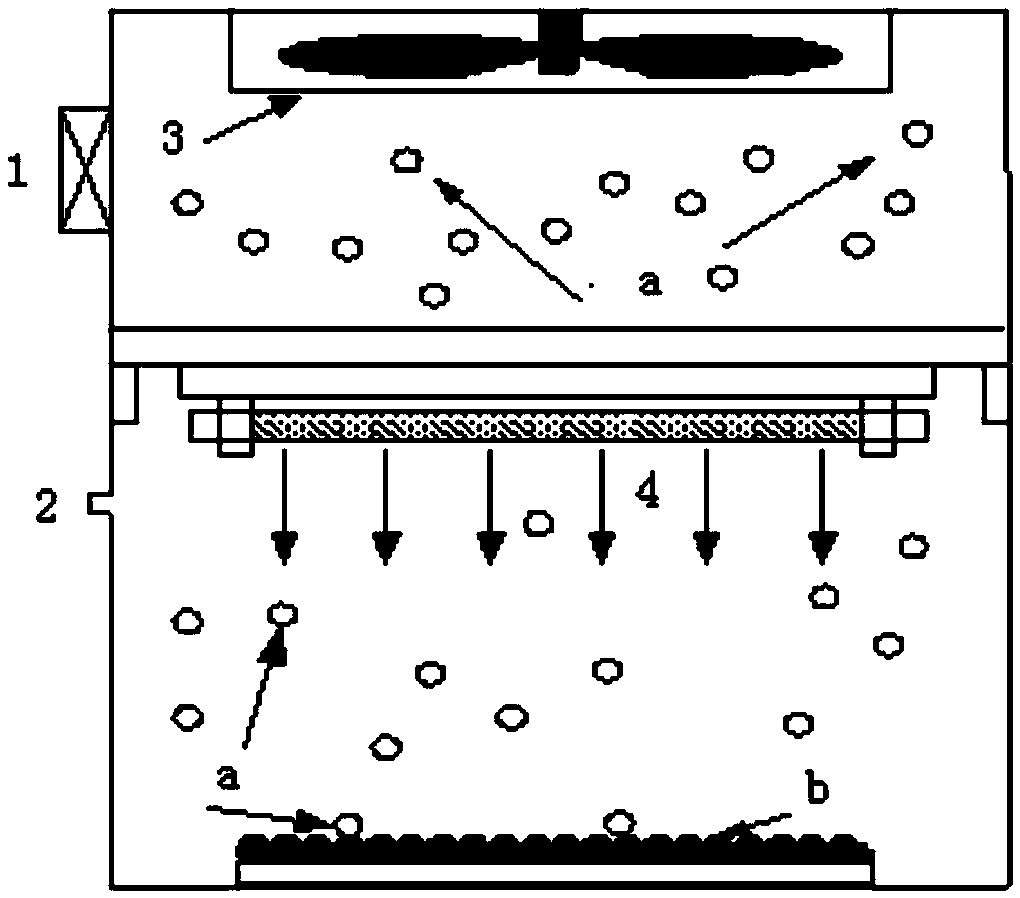

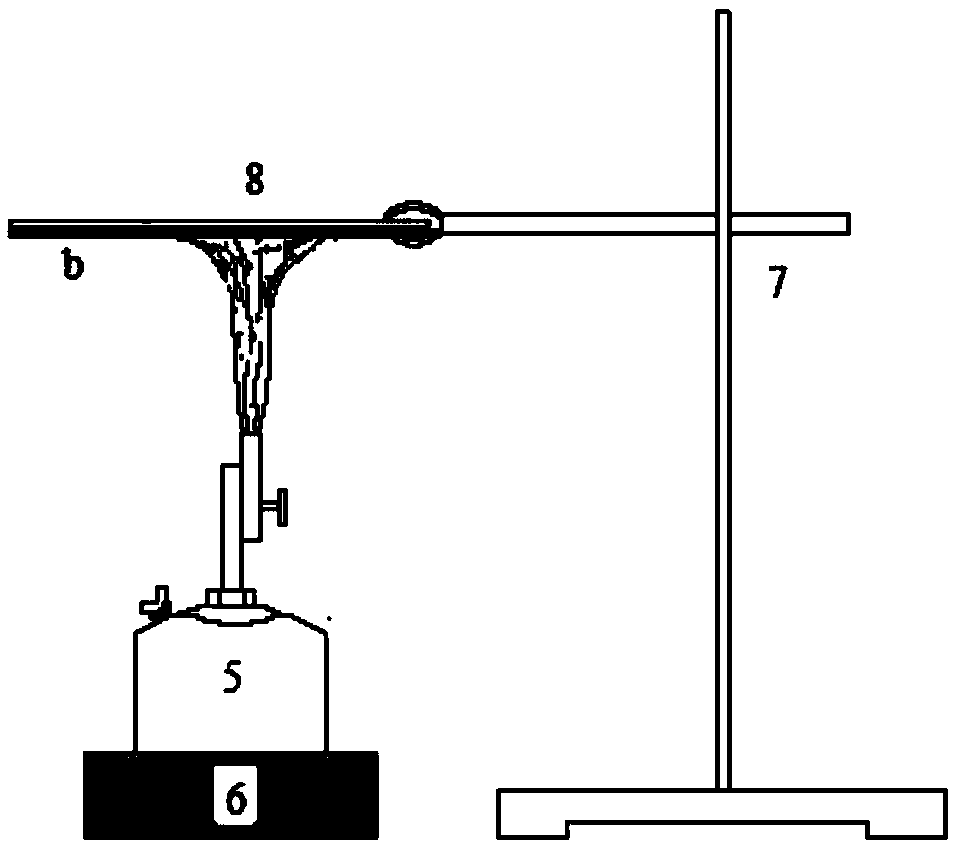

Method used

Image

Examples

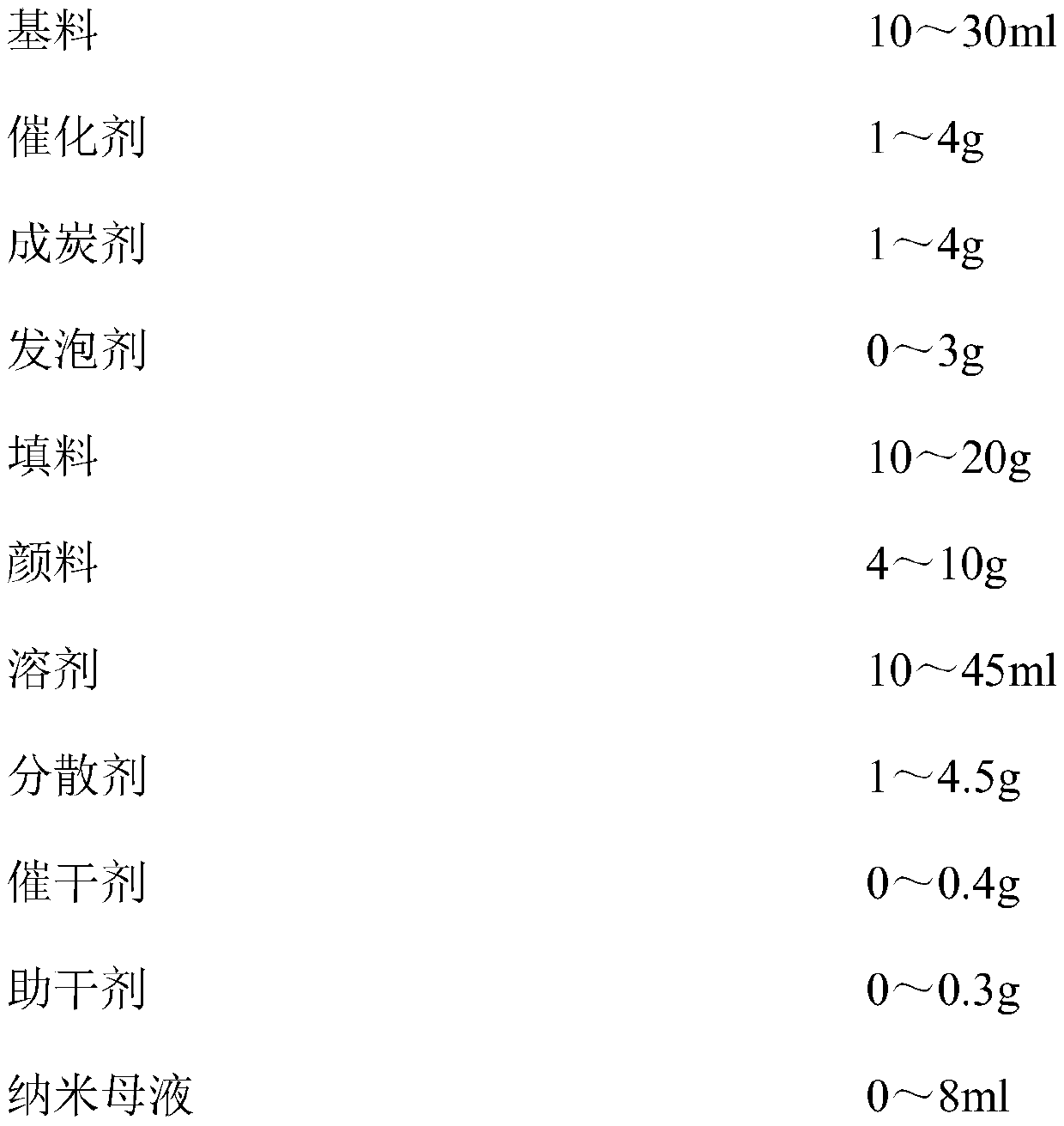

Embodiment 1

[0050] First add 4.5g dispersant (BYK180 polymer dispersant, m 分散剂 :m 溶剂 =1:10), add 45ml of solvent (water), under high-speed stirring (1500 rpm), add base material (phosphoric acid, aluminum hydroxide) 10ml and filler (ultrafine slag powder, specific surface area 681m 2 / Kg, see Table 1 for the chemical composition of slag powder) 10g, stir for 5min after adding. Then add the pigment (Cu-La / TiO 2 ) 4g, and then stirred for 5min. Reduce the rotation speed to 1000 rpm, add 1g of catalyst (ammonium polyphosphate), 1g of charring agent (pentaerythritol) and 2g of blowing agent (melamine), and stir for about 30min to prepare fireproof white paste.

[0051] Add the above-mentioned fireproof white paste into the paint mixing tank, adjust the rotation speed of the stirring plate to 500 rpm, and then add 0.15g of pre-mixed drier (lead oxide) and 0.25g of drier (zinc powder) and nano-mother solution (nano-SiO 2 mother liquor) 1ml, and stirred for 20 minutes to obtain the required...

Embodiment 2

[0055] First add 35ml of solvent (water) to 3.5g of dispersant (BYK180 polymer dispersant, m dispersant: m solvent = 1:10), and add base material ( Phosphoric acid, aluminum hydroxide) 20ml and filler (ultrafine slag powder, same as Example 1) 16g, stir for 5min after adding. Then add the pigment (Cu-La / TiO 2 ) 6g, and then stirred for about 5min. Reduce the rotation speed to 1000 rpm, add 2g of catalyst (ammonium polyphosphate), 2g of charring agent (pentaerythritol) and 3g of foaming agent (melamine), stir for 30min, and prepare fireproof white paste.

[0056] Add the above-mentioned fireproof white paste into the paint mixing tank, adjust the rotation speed of the stirring plate to 500 rpm, and then add 0.2g of pre-mixed drier (lead oxide) and 0.1g of drier (zinc powder) and nano-mother solution (nano-SiO 2 mother liquor) 7ml, and stirred for 20 minutes to obtain the required fireproof coating with photocatalytic properties using slag.

Embodiment 3

[0058] First add 2.5g dispersant (BYK180 polymer dispersant, m 分散剂 :m 溶剂 =1:10), add 25ml of solvent (water), under high-speed stirring (rotating speed is 1500 rpm), add 15ml of base material (phosphoric acid, aluminum hydroxide) and filler (ultrafine slag powder, same as in Example 1) ) 14g, stir for 5min after the addition. Then add the pigment (Cu-La / TiO 2 ) 8g, and then stirred for about 5min. Reduce the speed to 1000 rpm, add 2g of catalyst (ammonium polyphosphate), 2g of charring agent (pentaerythritol) and 1g of blowing agent (melamine), stir for 30min, and prepare fireproof white paste.

[0059] Add the above-mentioned fireproof white paste into the paint mixing tank, adjust the rotation speed of the stirring plate to 500 rpm, and then add 0.3g of drier (lead oxide) and 0.2g of drier (zinc powder) mixed in proportion in advance and nano-mother solution (nano-SiO 2 mother liquor) 5ml, and stirred for 20 minutes to obtain the required fireproof coating with photocat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com