Ultra-flexible self-generating yarn, all-fiber-based ultra-flexible temperature-difference self-generating fabric and preparation method thereof

An ultra-flexible, self-generating technology, applied in fabrics, fiber processing, knitting, etc., can solve the problems of uniformity and stability of power generation, limited power generation efficiency, inconvenient integration and use of wearable micro-nano electronic devices, etc. Achieve good uniformity of power generation, improve power generation efficiency and integration, and realize the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

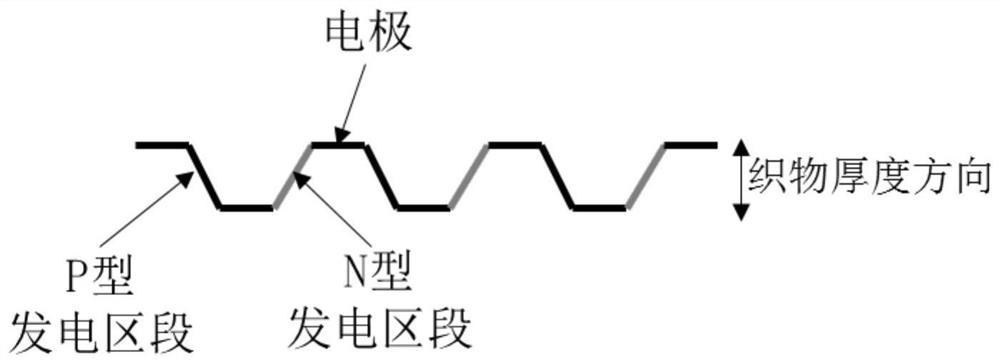

[0049] The preparation method of the self-generating yarn is to first prepare the P-type thermoelectric material region and / or the N-type thermoelectric material region and the electrode, and then press the P-type thermoelectric material region and / or the N-type thermoelectric material region and the electrode. Or weave the P-type thermoelectric material area and / or the N-type thermoelectric material area first, and then knit into the fabric according to the position of the P-type thermoelectric material area and / or the N-type thermoelectric material area, and finally Electrodes are prepared from the portion of the generating yarn that is on the surface of the fabric.

[0050] The present invention also provides a preparation method of an all-fiber-based ultra-flexible thermoelectric self-generating fabric, comprising the following steps:

[0051] S1. Add DMSO with a volume fraction of 5% to the basic P-type thermoelectric material, prepare a solution containing PEDOT:PSS by u...

Embodiment 1

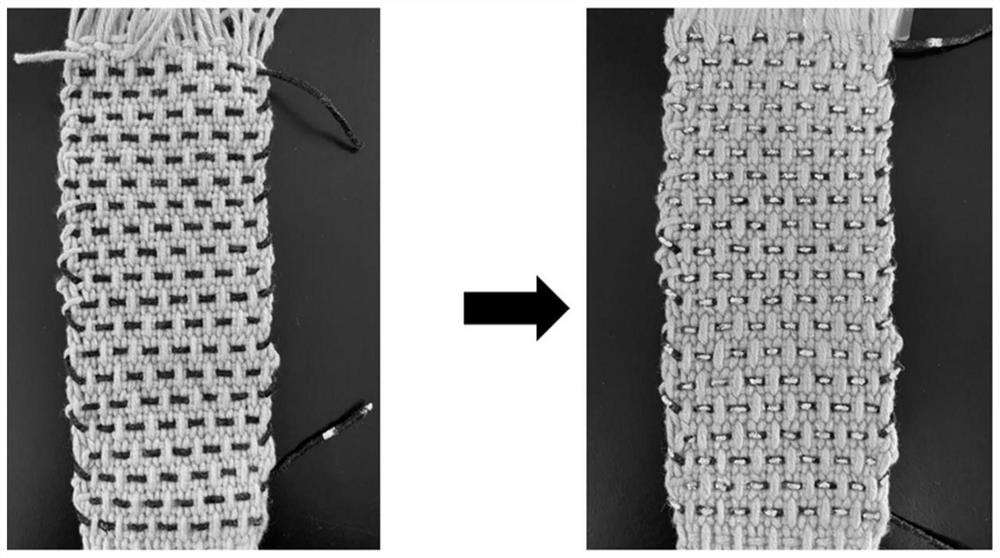

[0066] An all-fiber-based ultra-flexible thermoelectric self-generating fabric is prepared through the following steps:

[0067] S1. To the PEDOT:PSS aqueous solution (specification: Clevios PH1000) with a mass fraction of 1.3%, add DMSO with a volume fraction of 5%, and prepare a solution containing PEDOT:PSS by ultrasonic treatment (ultrasonic treatment time is 30-45 min), Then add 1-ethyl-3-methylimidazolium dicyanoammonium salt (EMIM DCA) with a total mass of 1 wt % of the PEDOT:PSS aqueous solution, and fully stir to form a uniform IL / PEDOT mixed solution, that is, a P-type thermoelectric material solution (stirred). The temperature is 25 °C, the stirring speed is 600 r / min, and the stirring time is 15h); the addition of ionic liquid to the basic thermoelectric material can form a complete film on the surface of the yarn, maintain the flexibility of the yarn itself, and can obtain ultra-high temperature. Flexible power-generating yarn. In addition, the addition of ionic ...

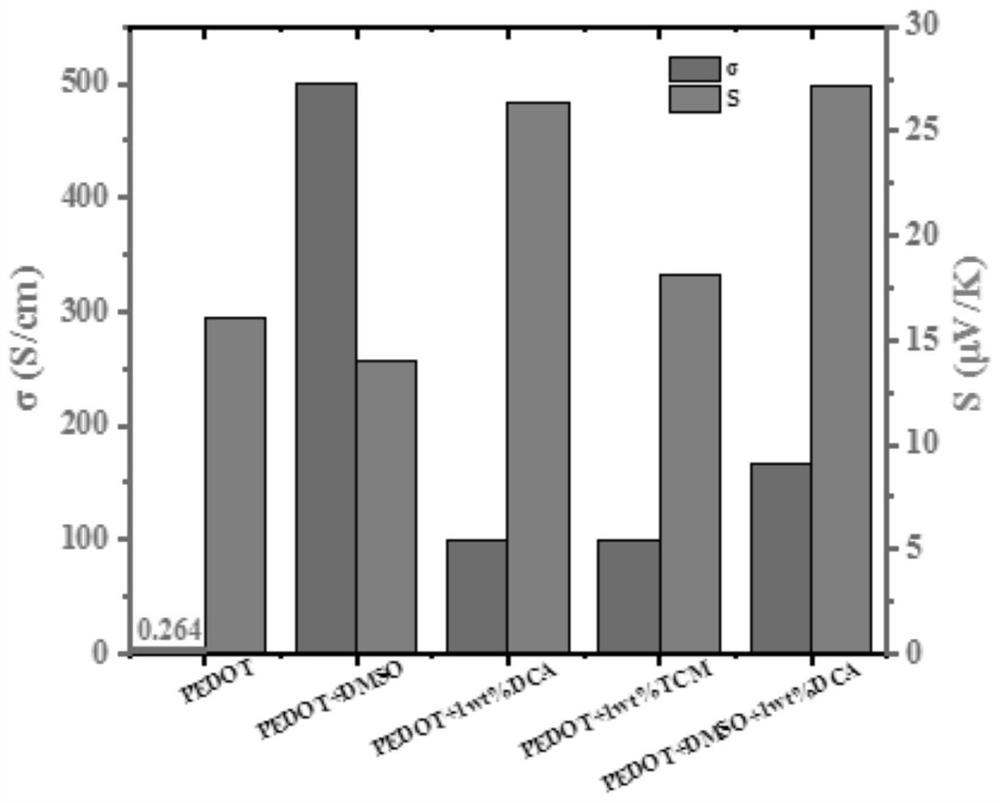

Embodiment 2-5 and comparative example 1

[0075] An all-fiber-based ultra-flexible thermoelectric self-generating fabric, compared with Example 1, is different in that in step S1, the types and contents of ionic liquids are shown in Table 1. Others are substantially the same as those in Embodiment 1, and are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com