A new type of large-span rib beam composite plate and construction method

A construction method and large-span technology, applied in the processing of floors, building materials, construction, etc., can solve the problems of increased installation difficulty, increased cost, and easy bending of laminated panels, so as to reduce installation difficulty and improve structural stability , Enhance the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

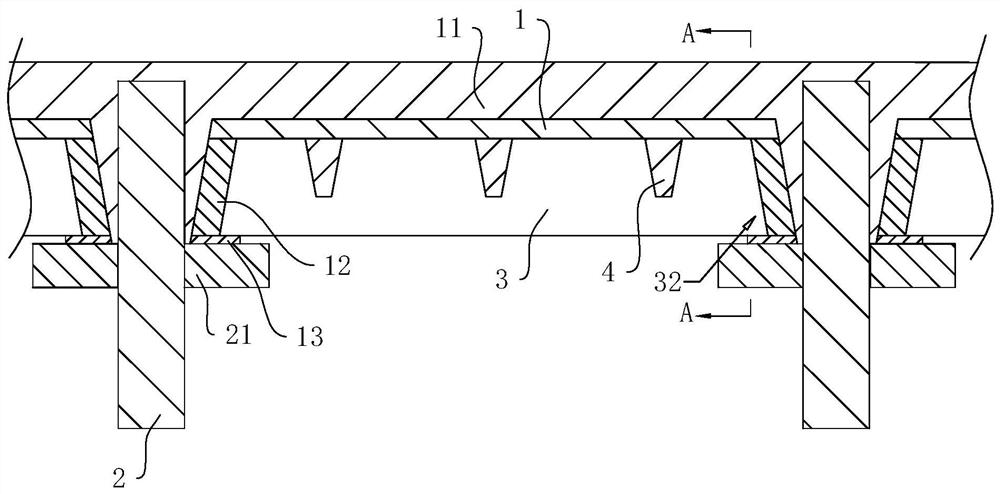

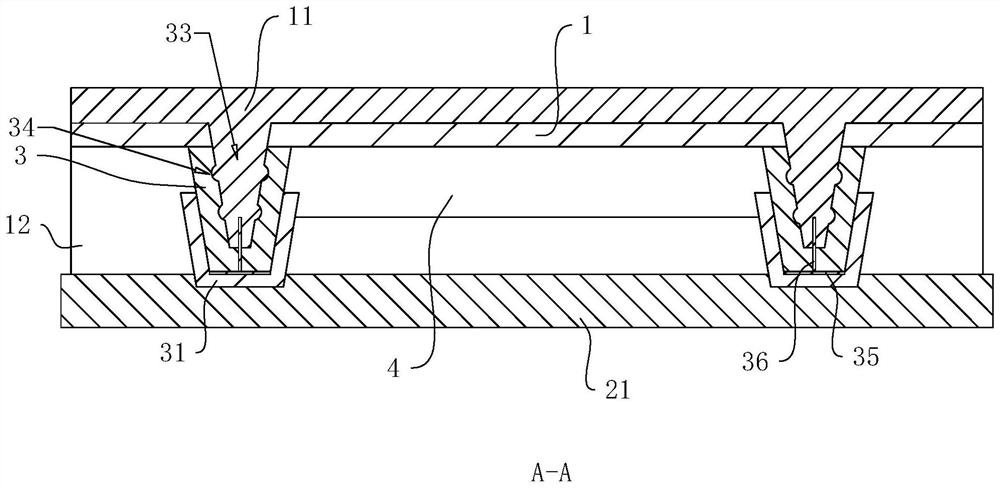

[0038] Attached to the following Figure 1-3 This application will be described in further detail.

[0039] The embodiment of the present application discloses a novel large-span rib beam laminated board. like figure 1 As shown in the figure, a new type of large-span rib beam composite panel includes a prefabricated panel 1 and a superimposed concrete layer 11. The prefabricated panel 1 has a rectangular plate-like structure, and the prefabricated panel 1 is arranged between two rows of columns 2. Multiple columns in the same row A beam 21 is fixedly connected between the 2, the two ends of the prefabricated panel 1 along the length direction are connected between the two beams 21, and the superimposed concrete layer 11 is arranged on the bearing surface of the prefabricated panel 1 and the top of the column 2.

[0040] like figure 1 and figure 2 As shown, both ends of the prefabricated board 1 along the length direction are bent and extended with diagonal braces 12. From...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com