Stator assembly, magnetic suspension bearing and compressor

A component and stator technology, applied in the field of magnetic suspension, can solve problems such as rotor instability, rotor air gap changes, damage to the rotor dynamic balance structural strength, etc., to achieve the effect of improving operational stability and effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

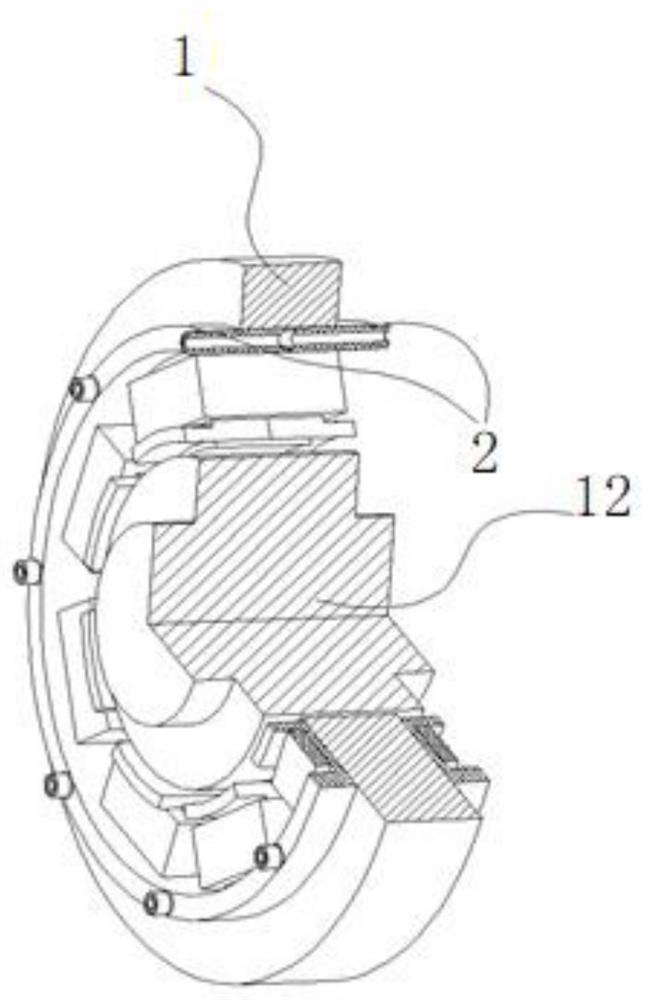

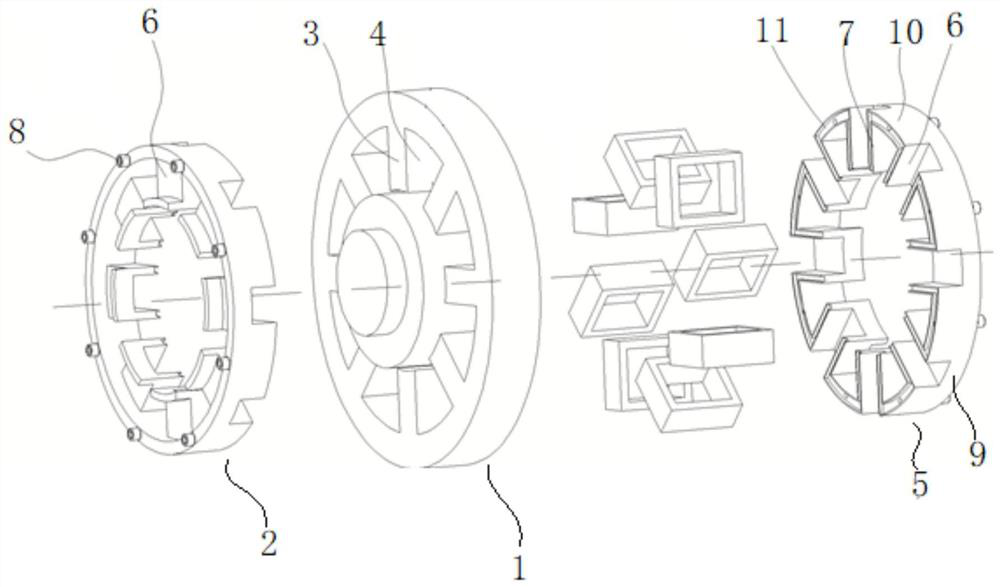

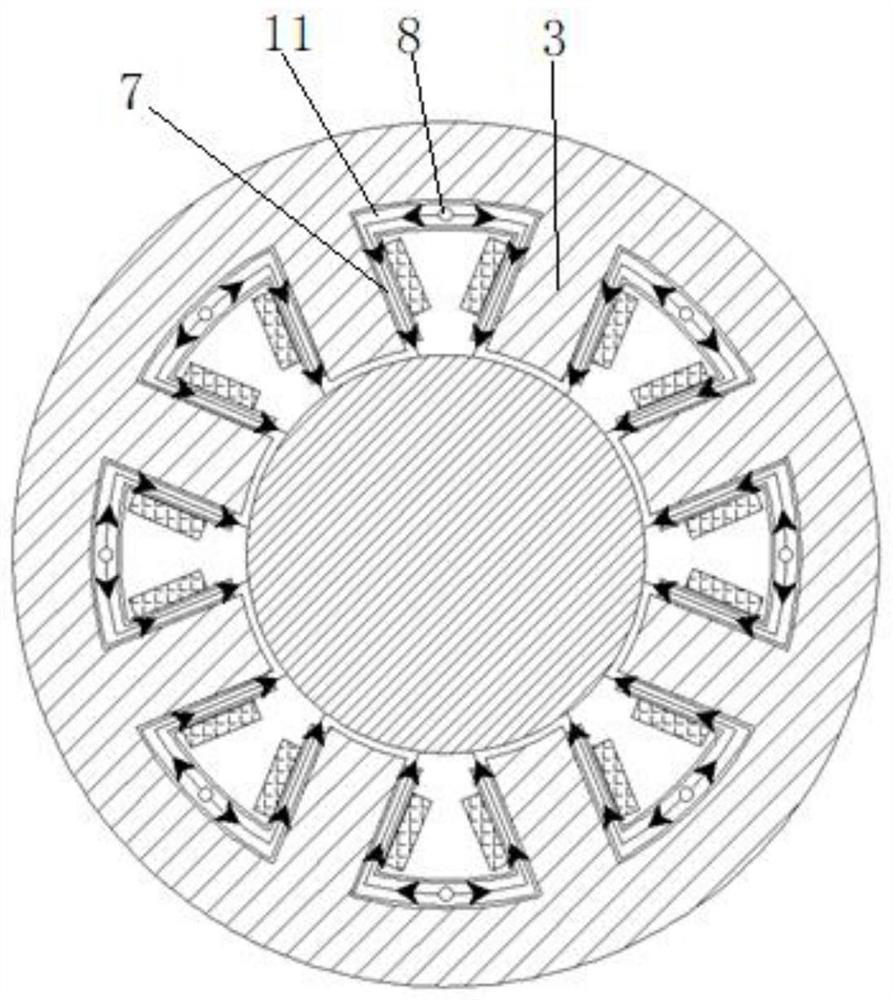

[0022] see in conjunction Figure 1 to Figure 3 As shown, according to the embodiment of the present application, the stator assembly includes a stator core 1 and a stator frame 2 arranged at both ends of the stator core 1, the stator core 1 includes stator teeth 3 and stator slots 4, and the stator frame 2 includes an insulating yoke 5 and an insulating tooth portion 6, the insulating yoke portion 5 is connected to the insulating tooth portion 6, the insulating tooth portion 6 is wrapped outside the stator tooth 3, the insulating tooth portion 6 includes a slot for installing the stator tooth 3, at least one tooth on the stator frame 2 The end surface of the groove away from the bottom of the groove is provided with a first cooling channel 7, and the end of the stator frame 2 away from the first cooling channel 7 is provided with an inlet channel 8, which communicates with the first cooling channel 7, and the first The cooling channel 7 communicates with the central hole of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com