Line pipe classifying and tightening device for intelligent manufacturing

A technology of intelligent manufacturing and wire tubes, applied in the direction of electrical components, etc., can solve the problems of long-term layout time, cumbersome wire tube layout, and increased manual operation costs, so as to prevent shifting positions, improve aesthetics, and prevent circuit Effect of Security Questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

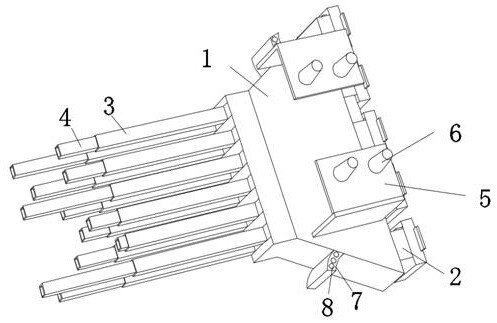

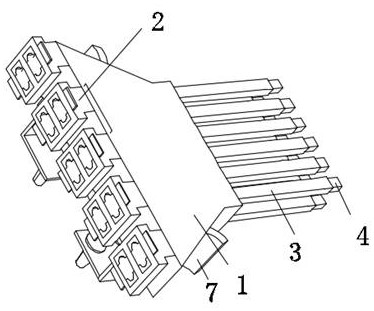

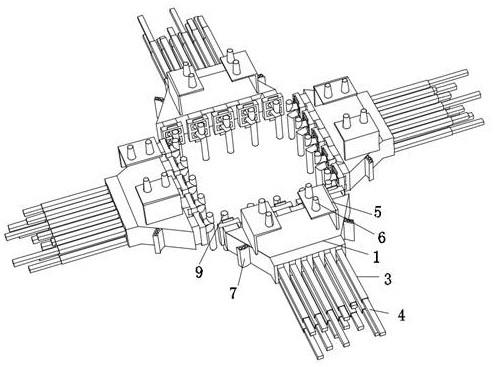

[0039] refer to Figure 1-15 , the wire tube sorting and tightening device for intelligent manufacturing in this embodiment includes a plurality of sorting tubes 1 connected by connecting components, the sorting tube 1 is a hollow structure, and one side of the sorting tube 1 is fixedly installed with multiple tightening Seat 2, one side of the tightening seat 2 is also provided with a clamping chamber 22 communicating with the classification pipe 1, and the other side of the tightening seat 2 is detachably and fixedly installed with a plurality of first pipes 3, the first pipe 3 and the tightening Between the seat 2 is provided with a movable buckle assembly used in conjunction, and a plurality of first pipes 3 communicate with a plurality of tightening seats 2 in one-to-one correspondence, and a second pipe 4 is slidably installed in the first pipe 3 , and A limiting assembly for damping and limiting the movement of the first pipe 3 and the second pipe 4 is provided, and a c...

Embodiment 2

[0041] Improvement on the basis of embodiment one:

[0042] When multiple classification pipes 1 are connected, they are connected using a connection assembly. The connection assembly includes arc-shaped connection plates 7 fixedly installed on both sides of the classification pipe 1. The top of the arc-shaped connection plate 7 is provided with a plurality of threaded holes 8, and the adjacent The same arc-shaped connection block 10 is arranged between the two classification pipes 1, and an arc-shaped connection groove is arranged in the arc-shaped connection block 10, and the sides of the two arc-shaped connection plates 7 that are close to each other extend into the arc-shaped connection groove The top of the arc-shaped connection block 10 is threaded with two symmetrically arranged fixing bolts 11, and the bottom of the fixing bolts 11 extends into the threaded hole 8 on the top of the corresponding arc-shaped connecting plate 7 and is threaded with the threaded hole 8, Wh...

Embodiment 3

[0044] The basic improvement in the second embodiment: two second linear bearings 28 symmetrically arranged are fixedly installed on one side of the inner wall of the clamping cavity 22, and the second connecting rod 27 passes through the inner ring of the corresponding second linear bearing 28 and connects with the second linear bearing 28. The inner ring of the bearing 28 is slidingly connected. The elastic component includes two symmetrically arranged rectangular grooves 32 on the inner wall of the bottom of the clamping cavity 22. The bottom of the clamping block 20 is fixedly equipped with a fixing plate 34, and the bottoms of the two fixing plates 34 respectively extend Into the corresponding rectangular groove 32, the same sliding rod 33 is fixedly installed on the inner walls of both sides of the rectangular groove 32, the sliding rod 33 runs through the fixing plate 34 and is slidably connected with the fixing plate 34, and the outer side of the sliding rod 33 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com