Water soluble flavor compositions, methods of making and methods of use thereof

A composition and substance technology, applied in the field of sweeteners and flavors, which can solve the problems of insufficient imitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

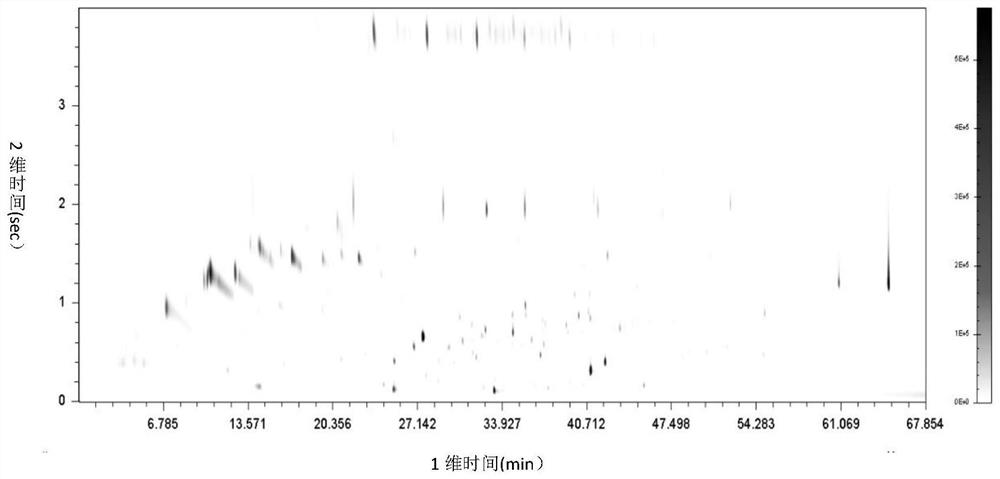

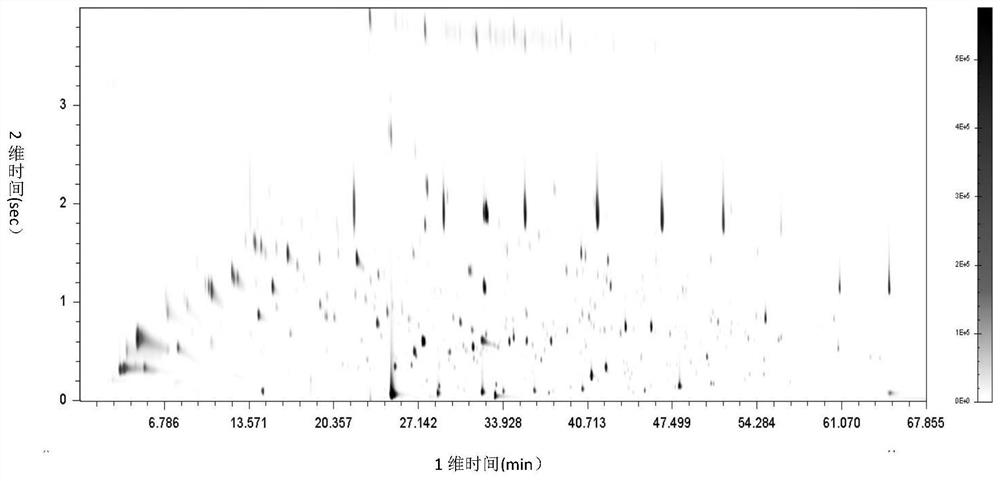

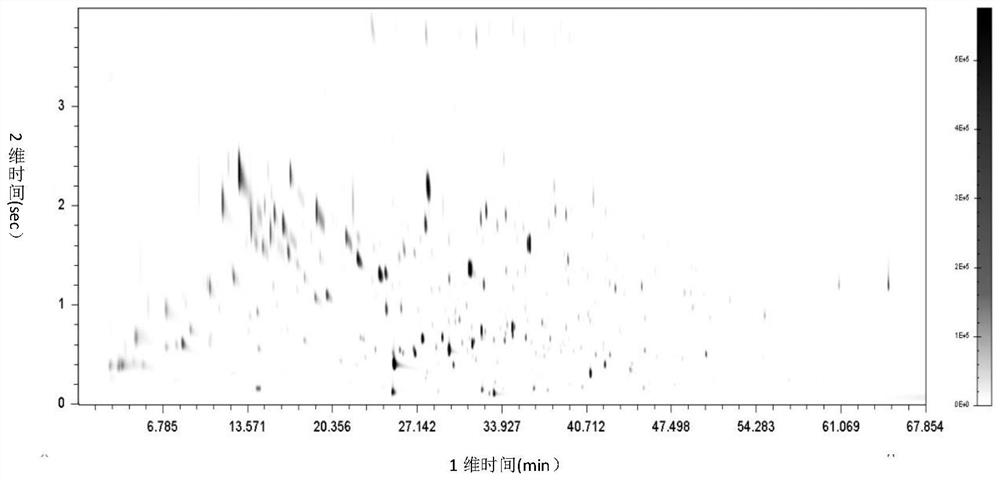

[1299] Example 1: Analysis of Steviol Glycosides and Volatile Organic Compounds in Stevia Extracts by Liquid Chromatography and Integrated Two-Dimensional Gas Chromatography Time-of-Flight Mass Spectrometry

[1300] sample

[1301] Stevia extract 1-1#, 1-2#, 1-3#, 1-4#. All samples are available from Sweet Green Fields, LLC.

[1302] method

[1303] Steviol Glycosides Test

[1304] According to JECFA 2010, steviol glycosides were detected by HPLC at 210 nm.

[1305] Testing for Volatile Organic Substances

[1306] Sample Preparation

[1307] Solid phase microextraction (SPME) was applied using a manual fiber holder (Supelco, USA) and PDMS / CAR / DVB fibers (Supelco, USA). Each sample (0.8 g) was placed in a 20 mL headspace vial, dissolved in 0.2 g / ml aqueous NaCl (5 ml), and conditioned at 60°C for 15 minutes. After extracting the samples for 30 min, the fibers were thermally desorbed in a GC inlet at 250 °C for 3 min.

[1308] instrument

[1309] Agilent 7890B GC

[13...

Embodiment 2

[1397] Example 2. Preparation of Flavored Stevia Extract 2-4#-MRP-TG with Stevia Extract, Glutamic Acid and Galactose

[1398] Stevia Extract: Lot #2-4# available from Sweet Green Fields, LLC.

[1399] 10 g of Stevia extract 2-4#, 0.27 g of galactose and 0.83 g of glutamic acid were mixed. The ratio of galactose to glutamic acid is 3:1, and the ratio of stevia extract to a mixture of galactose and glutamic acid is 9:1. The obtained mixture was then dissolved in 35 g of pure water. Let the pH be its actual value (about 5) without adding any pH adjuster. The solution was then heated at approximately 100°C for 2 hours. After the reaction was completed, the reaction mixture was filtered with filter paper, and the filtrate was dried with a spray drier. About 9 g of off-white powder 2-4#-MRP-TG were thus obtained.

Embodiment 3

[1400] Example 3. Preparation of glycosylated steviol glycosides 2-4#-GSG with stevia extract 2-4#

[1401] Glycosylation products of Stevia extract 2-4# were prepared according to the following method.

[1402] i) Dissolve 15g tapioca dextrin in 45ml deionized water

[1403] ii) Add 15g of Stevia extract 2-4# into the liquefied dextrin.

[1404] iii) 0.75ml CGTase enzyme and 15ml deionized water were added to the mixture and incubated at 69°C for 20 hours to glycosylate Stevia extract 2-4# with glucose molecules derived from tapioca dextrin.

[1405]v) The reaction mixture was heated to 85° C. for 10 minutes to inactivate CGTase, which was then removed through a filter.

[1406] vi) The resulting 2-4#-GSG solution contains glycosylated rebaudiosides, unreacted rebaudiosides, other non-steviol glycosides and unreacted dextrins. It is further decolorized and spray dried. 25 g of white powder 2-4#-GSG were thus obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com