Fruit and vegetable net sleeve cutting and bagging device

The technology of bagging device and fruit and vegetable net is applied in the field of fruit and vegetable net sleeve cutting and bagging device, which can solve the problems of low work efficiency, poor bagging effect, and increase of production cost of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

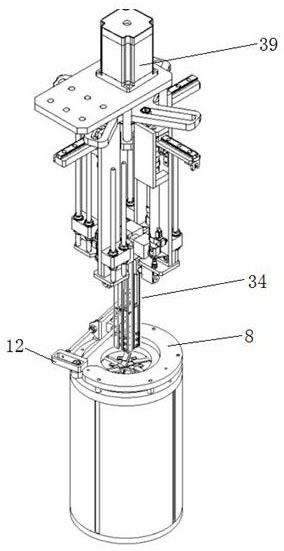

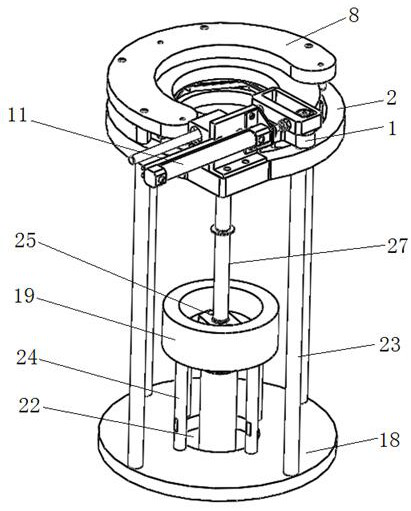

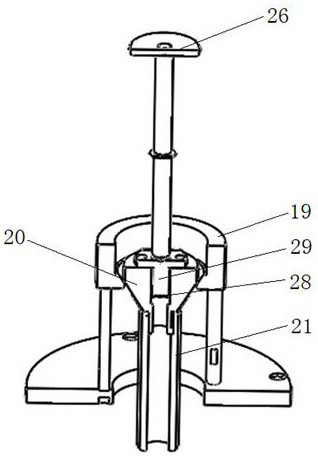

[0048] For the fruit and vegetable net cover cutting and bagging device of this embodiment, please refer to Figure 1-Figure 21 , including a net sleeve cutting mechanism for cutting the net sleeve and a bagging device arranged above the net sleeve cutting mechanism, wherein the net sleeve cutting mechanism includes a net sleeve cutting knife group, and the net sleeve cutting knife group includes bottom-up set Lower limit bracket 2, steering plate 1, upper limit bracket 8, six cutting knives 4 in circular layout are arranged between lower limit bracket 2 and steering plate 1, and six cutters 4 for driving are installed on lower limit bracket 2 The driving mechanism that opens or draws in, bagging device comprises the guide rail group that is made of concentric guide rail 30, all is installed on each guide rail 30 the guide rail slider 31 that can slide along its length direction, is provided with for driving on the guide rail group top. A plurality of guide rail sliders 30 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com