Asparagus yoghourt making method

A production method and technology of asparagus, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problem of lack of post-processing products and achieve the effect of diversification of eating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Step 1, taking a certain amount of yogurt and asparagus freeze-dried powder and pouring it into the stirring mechanism for stirring, wherein the weight ratio of yogurt and asparagus freeze-dried powder is 100:2.5;

[0072] Step 2, after the yogurt and asparagus freeze-dried powder are fully stirred, a mixed emulsion is formed, and the mixed emulsion is introduced into a forming mold;

[0073] Step 3, putting the molding mold containing the mixed emulsion into the freezer for freezing and finalizing to obtain the asparagus yoghurt block;

[0074] Step 4, demoulding the asparagus yoghurt liquid in a low temperature environment;

[0075] Step 5, put the asparagus yoghurt cubes after demoulding into the tray, and freeze-dry them;

[0076] In step six, the asparagus and yoghurt cubes that have been freeze-dried in step five are vacuum-packed in a dark place.

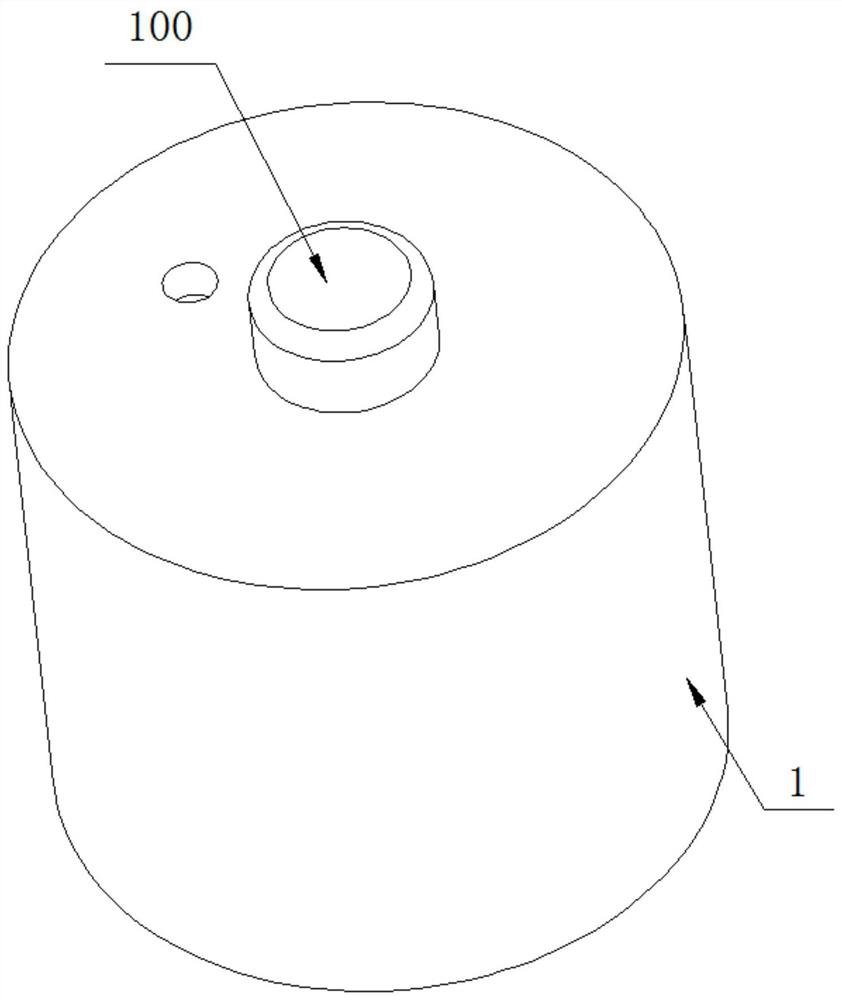

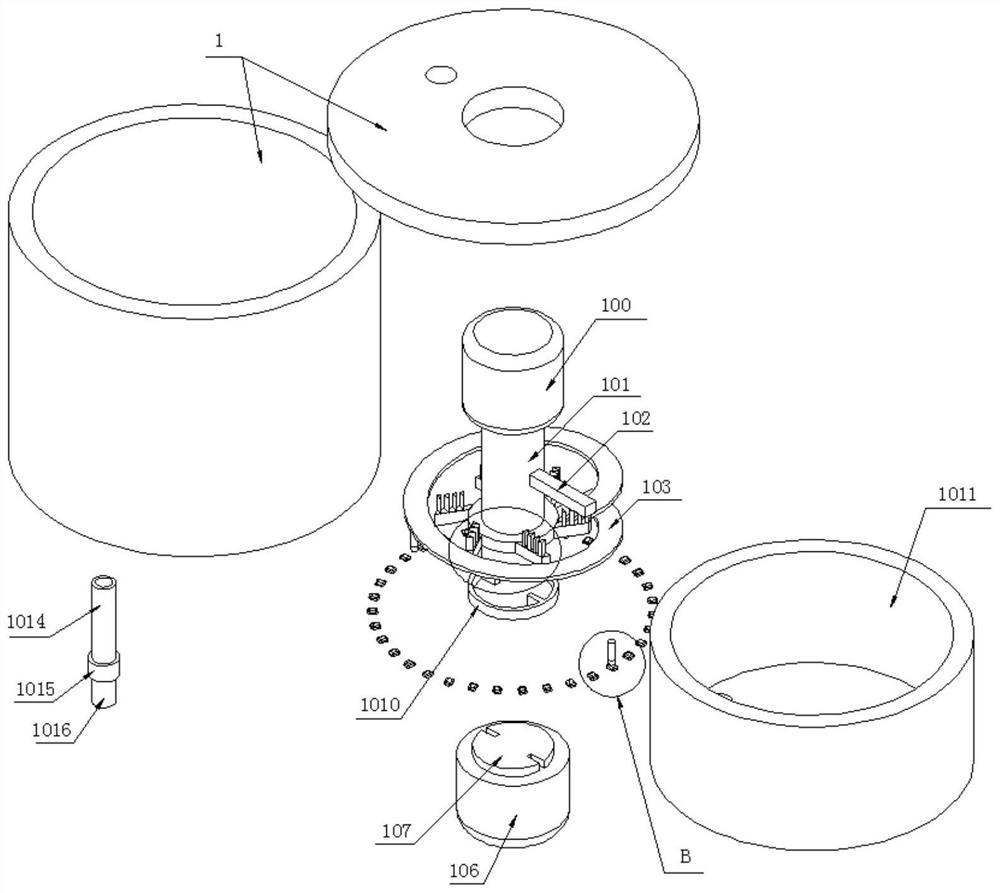

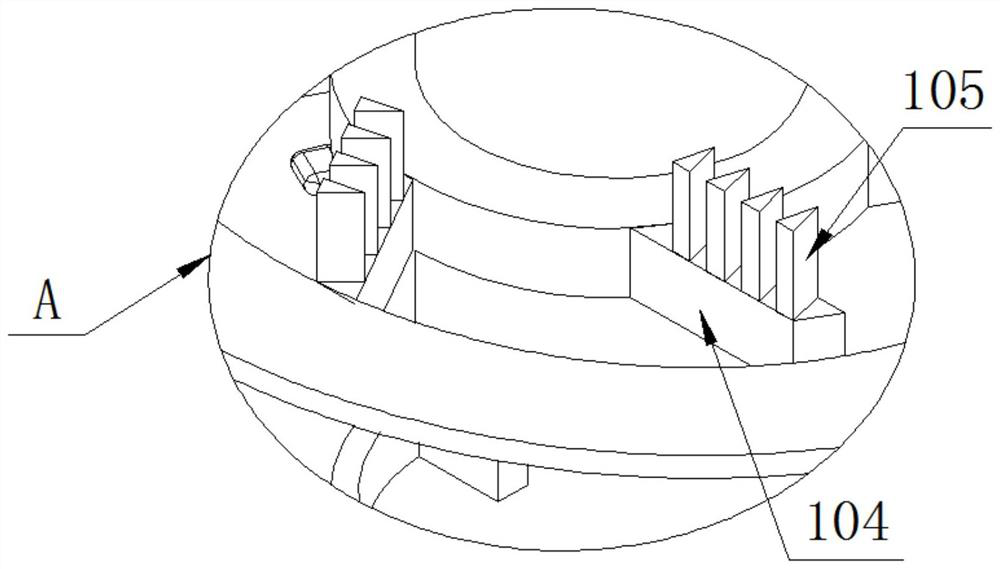

[0077] Further, in step one, the stirring mechanism includes a box body 1, a first drive motor 100 is fixedly inst...

Embodiment 2

[0091] Step 1, taking a certain amount of yogurt and asparagus freeze-dried powder and pouring it into the stirring mechanism for stirring, wherein the weight ratio of yogurt and asparagus freeze-dried powder is 100:2.5;

[0092] Step 2, after the yogurt and asparagus freeze-dried powder are fully stirred, a mixed emulsion is formed, and the mixed emulsion is introduced into a forming mold;

[0093] Step 3, putting the molding mold containing the mixed emulsion into the freezer for freezing and finalizing to obtain the asparagus yoghurt block;

[0094] Step 4, demoulding the asparagus yoghurt liquid in a low temperature environment;

[0095] Step 5, put the asparagus yoghurt cubes after demoulding into the tray, and freeze-dry them;

[0096] In step six, the asparagus and yoghurt cubes that have been freeze-dried in step five are vacuum-packed in a dark place.

[0097] Further, in step one, the stirring mechanism includes a box body 1, a first drive motor 100 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com