Crankshaft upsetting left and right die with hidden locking sliding pins

A mold, left and right technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as hidden safety hazards, eliminate hidden dangers, reduce production costs, and mold replacement efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

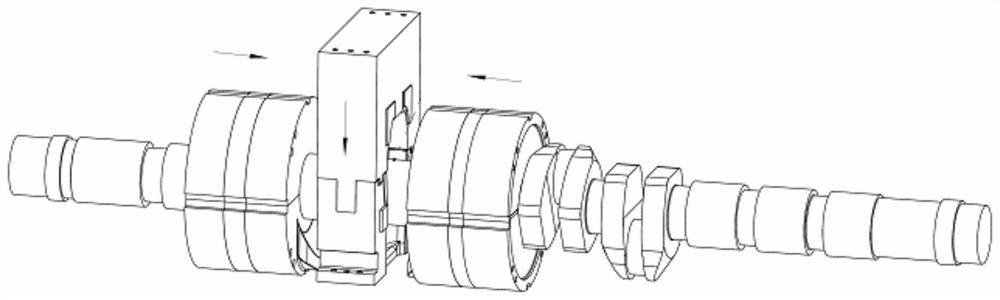

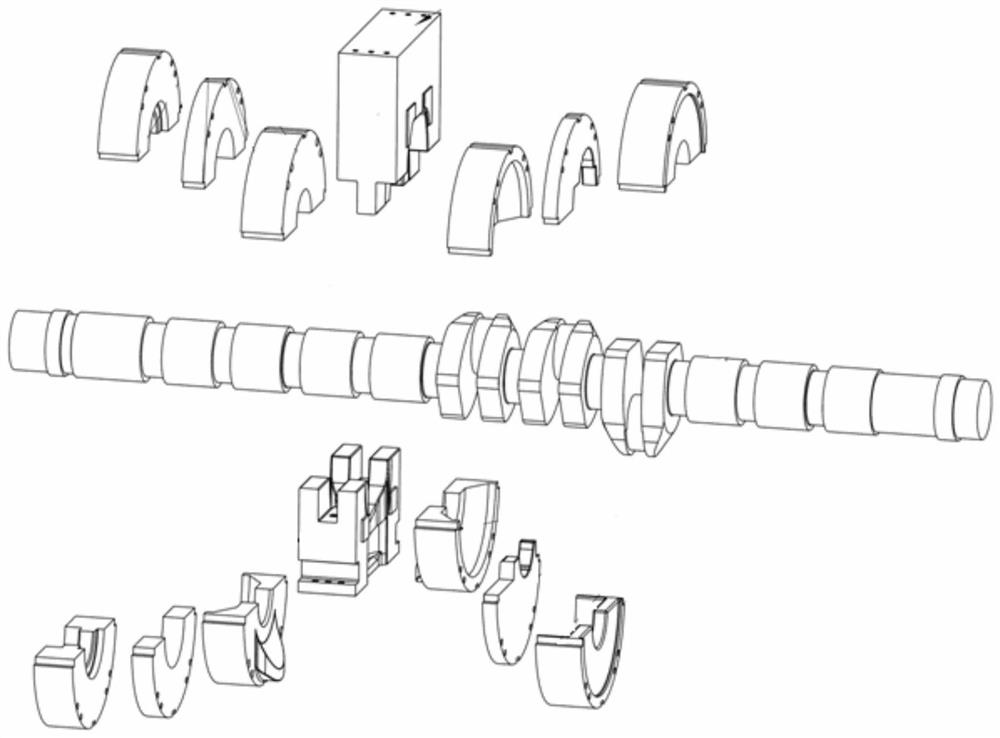

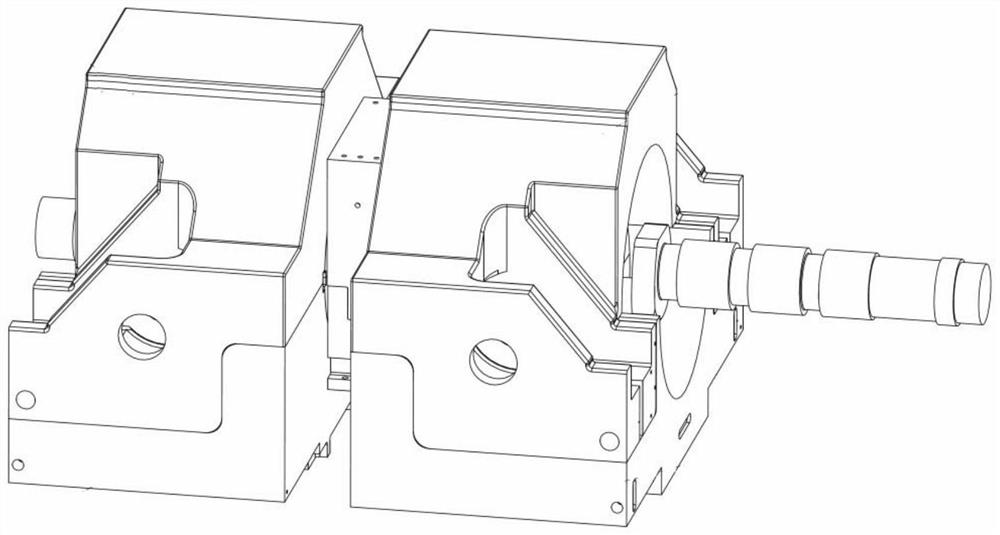

[0039] Such as Figure 6-16 As shown, a left and right mold for upsetting crankshaft with hidden locking sliding pin, including moving block tooling, mold, long hexagon socket head screw 20, backstop pressure block 14, sliding pin 15 and cylinder head hexagon socket head screw 19;

[0040] The moving block tooling is divided into a left upper moving block 1, a right upper moving block 2, a left lower moving block 3 and a right lower moving block 4;

[0041] Described mold is divided into the left side upper die combination mold 5, the right side upper mold combination mold 6, the left side lower mold combination mold 7 and the right side lower mold combination mold 8; Among the side upper mold combination mold 5, the right upper mold combination mold 6, the left lower mold combination mold 7 and the right lower mold combination mold 8, the first piece of mold 9 is close to the side edge of the movable block tooling;

[0042] Design and manufacture the groove a10 formed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com