Grinding device for machining butterfly valve for multifunctional ship

A multi-functional, marine technology, used in grinding drives, grinding/polishing safety devices, metal processing equipment, etc., it can solve the problem of not being able to drive the full range of grinding work, the grinding device has no external protection function, and the overall inconvenience of operation. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

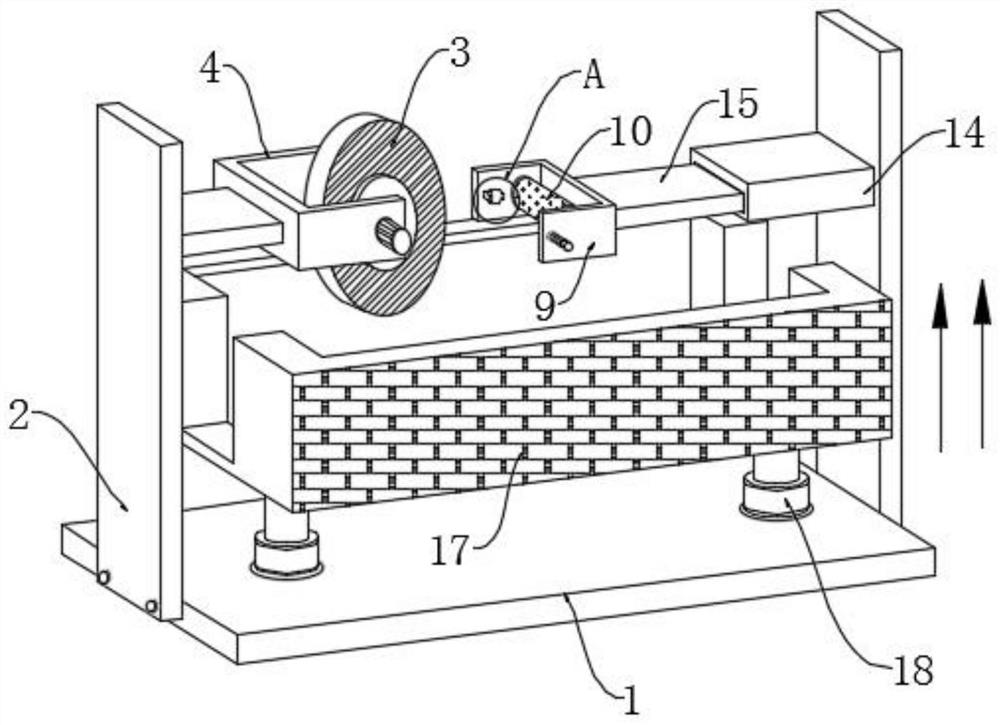

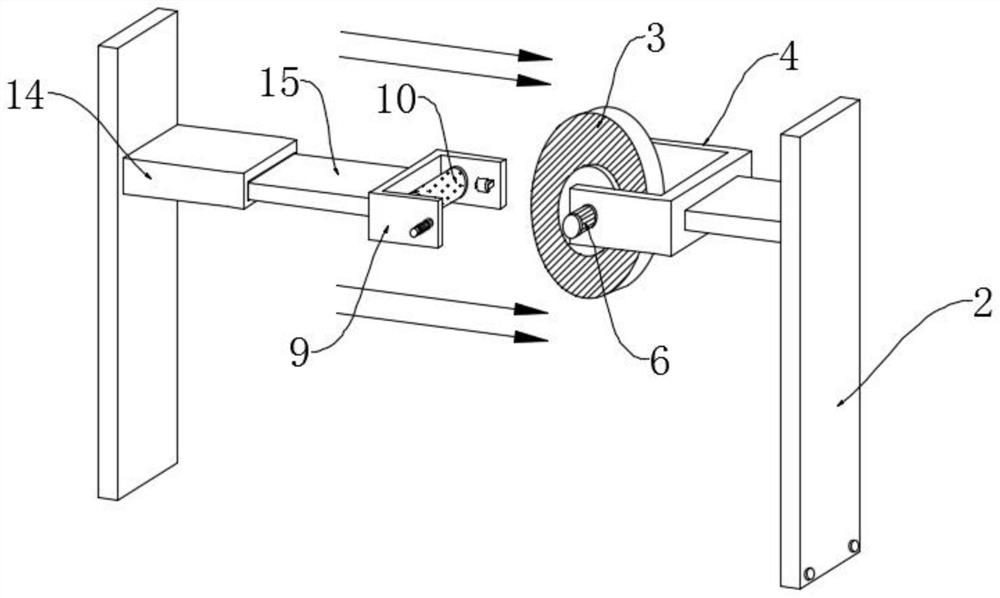

[0022] Such as Figure 1-5 As shown, the present invention provides a technical solution: a grinding device for multi-functional marine butterfly valve processing, including a base 1, two sets of reinforcement plates 2, a positioning assembly, a grinding assembly, a disc plate 3 and a protective assembly, the two sets of reinforcements The plate 2 is installed in parallel on both sides of the upper surface of the base 1, the positioning assembly is installed on the top side of the reinforcing plate 2, the grinding assembly is symmetrically installed on one side of the positioning assembly and connected with the reinforcing plate 2, and the disc plate 3 is assembled on the On the positioning assembly, the protective assembly is installed below the positioning assembly and the grinding assembly.

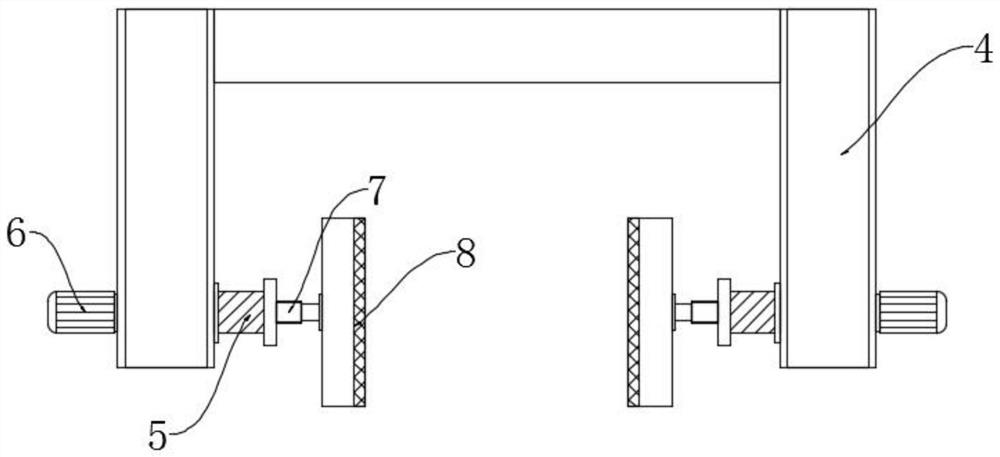

[0023] In this embodiment, specifically: the positioning assembly includes a positioning piece 4, two sets of linkage columns 5, two sets of driving motors 6, two sets of No. 1 cylinde...

Embodiment 2

[0027] In this embodiment, specifically: the protective assembly includes a protective cover 17 with an opening at the top, and two sets of No. 3 cylinders 18. The protective cover 17 is correspondingly installed above the base 1. The No. 3 cylinders 18 of the two groups pass through The bracket 12 is installed on both sides of the upper surface of the base 1, and the output end of the No. 3 cylinder 18 is attached to both sides of the lower surface of the protective cover 17, so that the protective cover 17 covers and protects the positioning assembly and the grinding assembly, avoiding the grinding process. There is a large amount of waste splashing in the machine, which improves the working environment of the operator.

[0028] In this embodiment, specifically: the protective cover 17 is made of a transparent material as a whole, and the two sides of the top of the protective cover 17 are correspondingly provided with slide rails corresponding to the positioning part 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com