Composite processing equipment for manufacturing multi-layer composite board

A composite processing and multi-layer composite technology, which is applied in the direction of manufacturing tools, wood processing equipment, plywood presses, etc., can solve the problem of glue accumulation, affecting the aesthetics of multi-layer composite boards for subsequent use, and multi-layer composite boards. Bulge etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

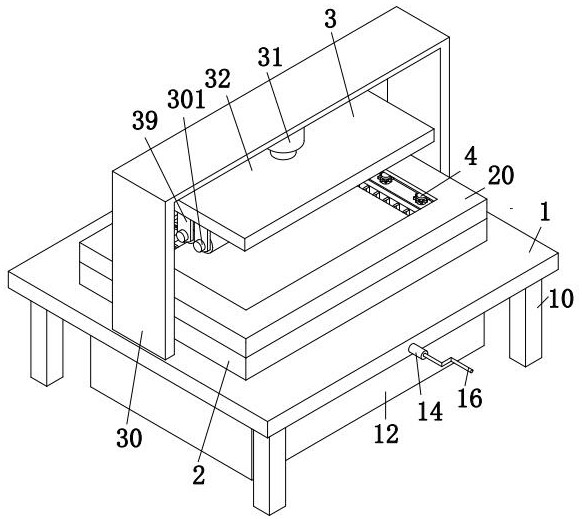

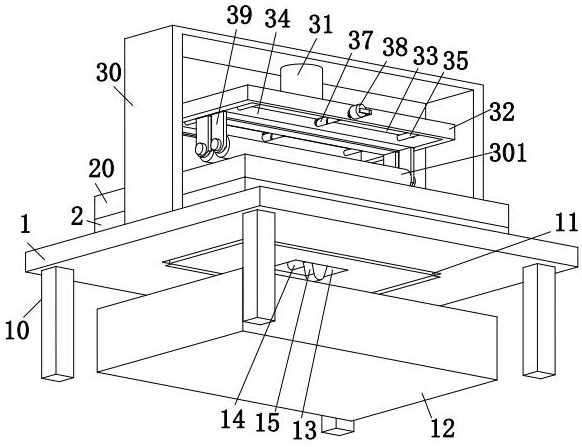

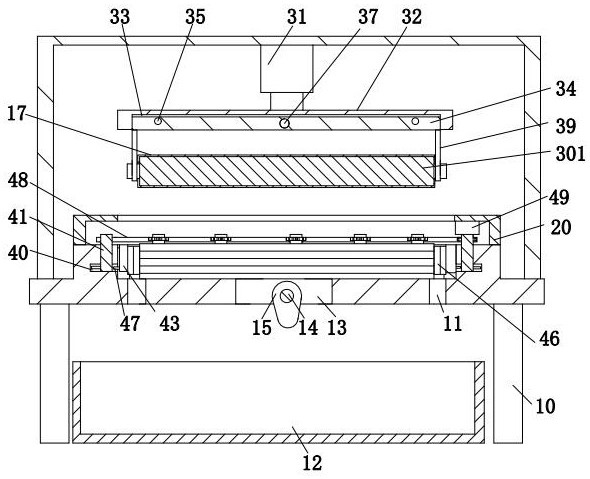

[0025] Such as Figure 1 to Figure 6 As shown, a composite processing equipment for the manufacture of multi-layer composite boards includes a workbench 1, a placement frame 2, a pressing mechanism 3 and a scraping mechanism 4, and the upper end surface of the workbench 1 is equipped with a placement frame 2 and a press Combining mechanism 3, placement frame 2 is a back-shaped structure, and scraping mechanism 4 is installed in placement frame 2.

[0026] The lower end surface of the workbench 1 is equipped with four support legs 10, the four support legs 10 are arranged in a matrix, and the lower end surface of the workbench 1 is provided with four unloading channels 11, the unloading channels 11 are located in the scraper Just be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com