Smooth wear-resistant self-repairing coating for flexible protective film of mobile phone, and preparation method thereof

A self-healing and smooth technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of jerky and rough sliding touch, which cannot meet the needs of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

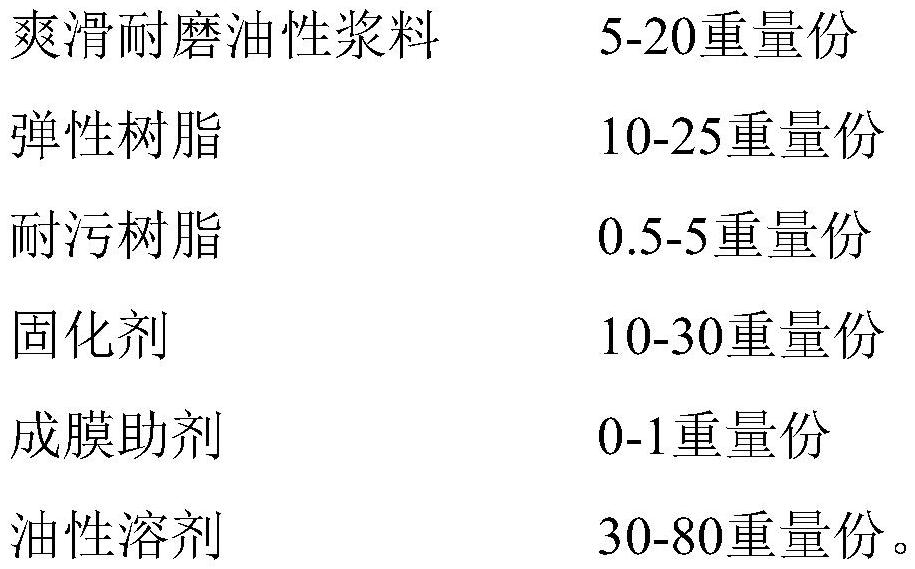

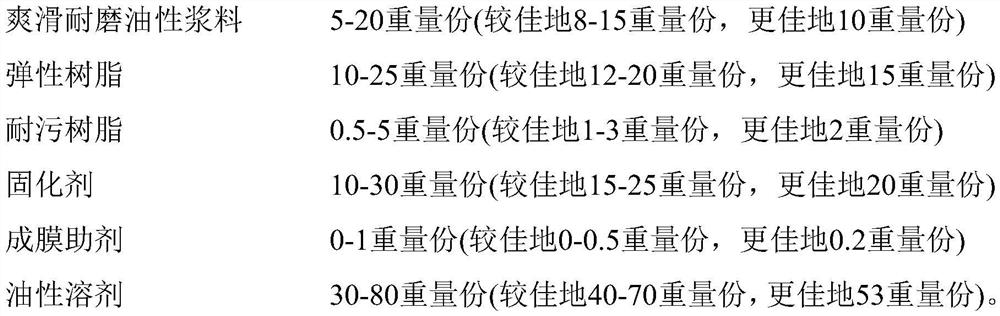

Method used

Image

Examples

Embodiment 1

[0086] Under normal temperature and pressure, mix 90% oily solvent, 5% smooth and wear-resistant powder and 5% polyacrylate type hyperdispersant evenly, grind and disperse at a high speed of 2000r / min for 2 hours to obtain smooth and wear-resistant oily slurry A; Mix 15 parts of elastic resin, 2 parts of stain-resistant resin, 20 parts of curing agent, 0.2 parts of film-forming aid, and 53 parts of oily solvent, and mix them at high speed at 1000r / min for 0.5h to obtain self-healing coating B; then mix 10 parts % smooth and wear-resistant oily slurry A and 90% self-repairing coating B were mixed evenly and mixed at a high speed of 1000r / min for 0.5h to obtain a smooth and wear-resistant self-repairing coating. Sample number: SH-1.

Embodiment 2

[0088] Under normal temperature and pressure, mix 90% oily solvent, 5% smooth and wear-resistant powder and 5% polyacrylate type hyperdispersant evenly, grind and disperse at a high speed of 2000r / min for 4 hours to obtain smooth and wear-resistant oily slurry A; Mix 15 parts of elastic resin, 2 parts of stain-resistant resin, 20 parts of curing agent, 0.2 parts of film-forming aid, and 53 parts of oily solvent, and mix them at high speed at 1000r / min for 0.5h to obtain self-healing coating B; then mix 10 parts % smooth and wear-resistant oily slurry A and 90% self-repairing coating B were mixed evenly and mixed at a high speed of 1000r / min for 0.5h to obtain a smooth and wear-resistant self-repairing coating. Sample number: SH-2.

Embodiment 3

[0090] Under normal temperature and pressure, mix 90% oily solvent, 5% smooth wear-resistant powder and 5% polyacrylate hyperdispersant evenly, grind and disperse at a high speed of 2000r / min for 6 hours to obtain smooth wear-resistant oily slurry A; Mix 15 parts of elastic resin, 2 parts of stain-resistant resin, 20 parts of curing agent, 0.2 parts of film-forming aid, and 53 parts of oily solvent, and mix them at high speed at 1000r / min for 0.5h to obtain self-healing coating B; then mix 10 parts % smooth and wear-resistant oily slurry A and 90% self-repairing coating B were mixed evenly and mixed at a high speed of 1000r / min for 0.5h to obtain a smooth and wear-resistant self-repairing coating. Sample number: SH-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com