Gas spring with flexible telescoping range

A gas spring and flexible technology, applied in the field of gas springs, can solve the problems of limited application scenarios of gas springs and small application scope of gas springs, and achieve the effects of improving flexibility, improving structural rationality, and simplifying production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

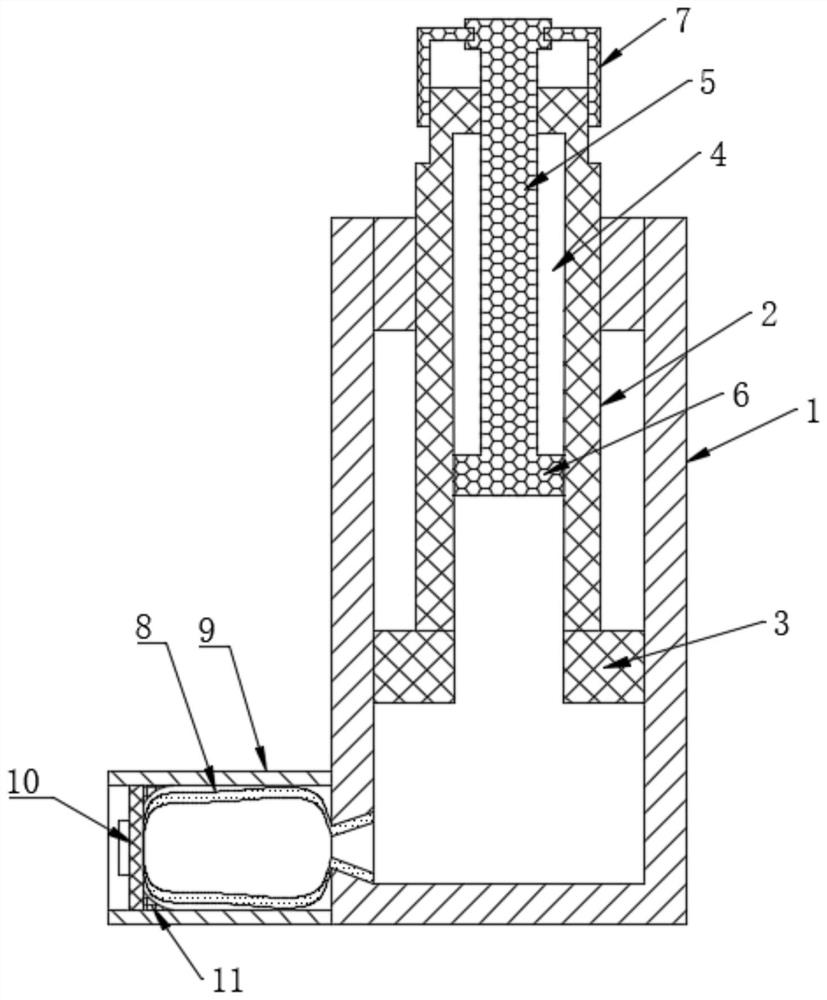

[0025] Embodiment: a gas spring with flexible range, such as figure 1 As shown, it includes a cylinder body 1, a piston rod 2 is inserted in the cylinder body 1, and the end of the piston rod 2 is provided with a piston head 3 that fits the inner wall of the cylinder body 1 to slide, and the cylinder body 1 is provided with an inert gas filled or oil-air mixture, the middle of the piston rod 2 is provided with a second stroke hole 4 along its own length direction, the piston rod 2 is provided with a second stroke rod 5 that fits and slides along the slide hole, and the end of the second stroke rod 5 is provided with a The second piston 6 with the interference fit of the second stroke hole 4 , the second stroke hole 4 passes through the piston head 3 and communicates with the inner cavity of the cylinder body 1 , and the second stroke rod 5 and the piston rod 2 are detachably fixed.

[0026] According to the scene where the gas spring is to be used, determine the stroke require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com