Non-sliding parallel shaft line gear mechanism with separable center distance

A technology of gear mechanism and center distance, applied in gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of lack of center distance separability, center distance error affecting the performance of line gear transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

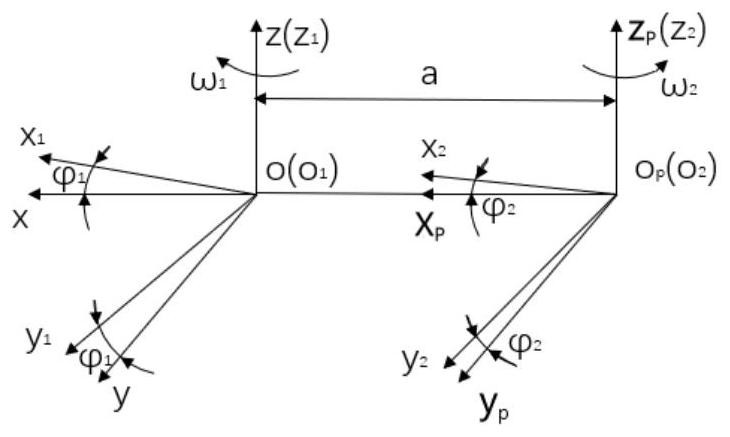

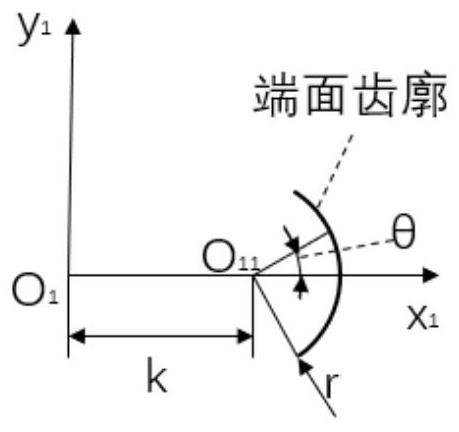

[0064] Given that the eccentricity k of the eccentric arc of the tooth profile of the driving wheel is 30, the radius r of the eccentric arc of the driving wheel is 8, and the variation range of the variable parameter of the eccentric arc of the driving wheel is 0°≤θ≤90°, the determined eccentricity of the driving wheel is obtained Arc tooth profile.

[0065] Further, given that the contact line pitch parameter is 50.92, it can be determined that when θ is 0, the corresponding The contact line is

[0066]

[0067] Further, the eccentric arc tooth profile of the driving wheel extends along the Sweep the contact line to get the tooth surface of the driving wheel tooth 1, and the equation of the tooth surface of the driving wheel tooth 1 in its own coordinate system is:

[0068]

[0069] -90°≤θ≤90°

[0070] 0≤t≤1.2π

[0071] Further, given that the transmission ratio is 0.5, the eccentricity of the eccentric arc of the driven wheel tooth profile and the radius of the ...

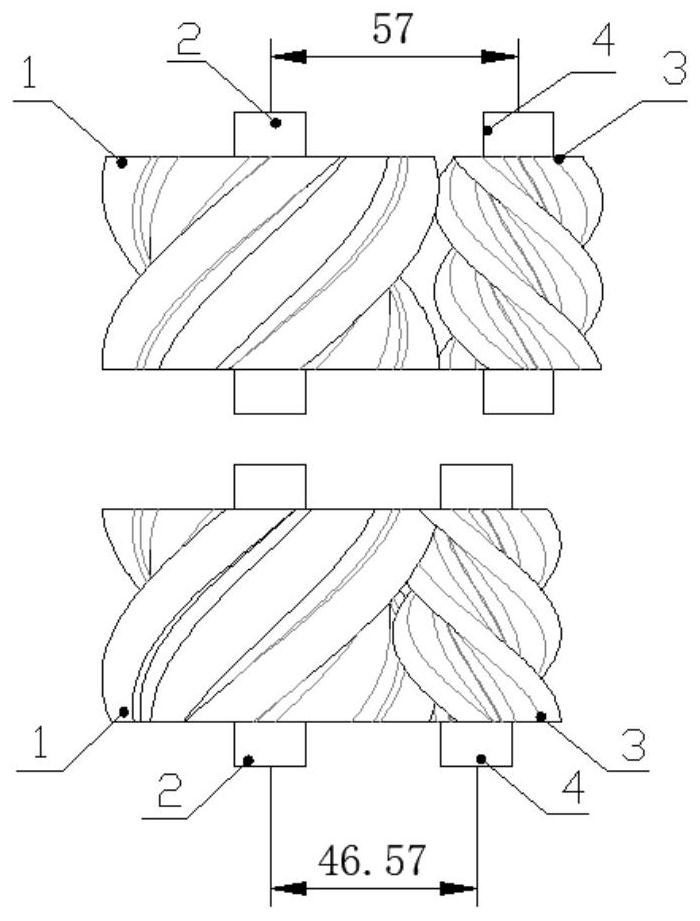

Embodiment 2

[0080] Given that the eccentricity k of the eccentric arc of the tooth profile of the driving wheel is 50, the radius r of the eccentric arc of the driving wheel is 8, and the variable parameter range of the eccentric arc of the driving wheel is 0°≤θ≤90°, the determined eccentricity of the driving wheel is obtained Arc tooth profile.

[0081] Further, given that the contact line pitch parameter is 100.46, it can be determined that when θ is 0, the corresponding The contact line is

[0082]

[0083] Further, the eccentric arc tooth profile of the driving wheel extends along the Sweep the contact line to get the tooth surface of the driving wheel tooth 1. Given the change range of the contact line length parameter is 0≤t≤0.4π, the equation of the driving wheel tooth 1 tooth surface in its own coordinate system is:

[0084]

[0085] -90°≤θ≤90°

[0086] 0≤t≤0.4π

[0087] Further, given that the transmission ratio is 0.5, the eccentricity of the eccentric arc of the dri...

Embodiment 3

[0096] Given that the eccentricity k of the eccentric arc of the tooth profile of the driving wheel is 40, the radius r of the eccentric arc of the driving wheel is 5, and the variation range of the variable parameter of the eccentric arc of the driving wheel is 0°≤θ≤90°, the determined eccentricity of the driving wheel is obtained Arc tooth profile.

[0097] Further, given that the contact line pitch parameter is 77.94, it can be determined that when θ is 0, the corresponding The contact line is

[0098]

[0099] Further, the eccentric arc tooth profile of the driving wheel extends along the Sweep the contact line to get the tooth surface of the driving wheel tooth 1. Given the change range of the contact line length parameter is 0≤t≤0.4π, the equation of the driving wheel tooth 1 tooth surface in its own coordinate system is:

[0100]

[0101] -90°≤θ≤90°

[0102] 0≤t≤0.4π

[0103] Further, given that the transmission ratio is 2, the eccentric distance of the ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com