Sampling and curing system and method for undisturbed sandy soil

An undisturbed, sandy soil technology, applied in the field of geotechnical engineering geotechnical testing, can solve the problems of undisturbed sandy soil frost heaving, inconvenient operation, damage to the internal structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

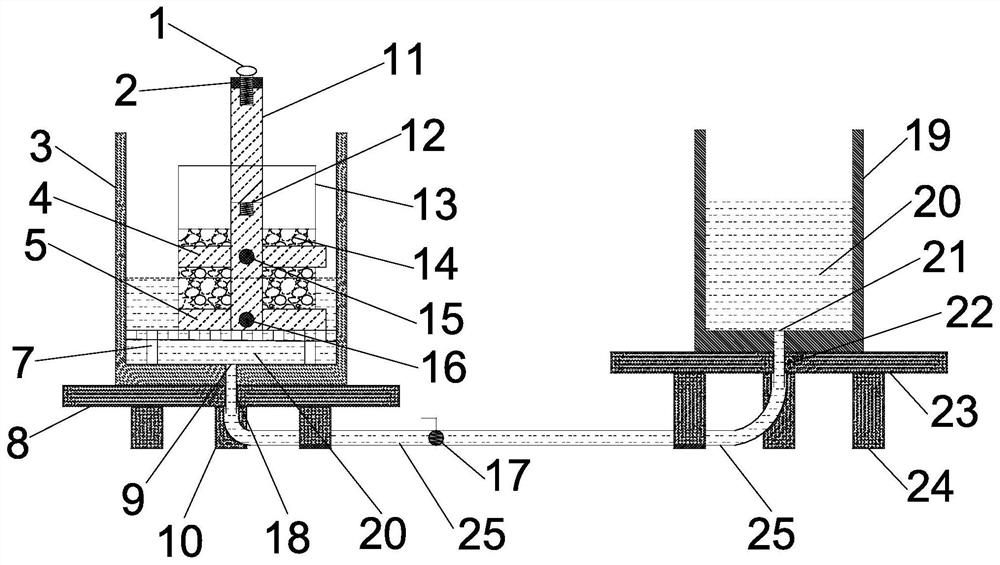

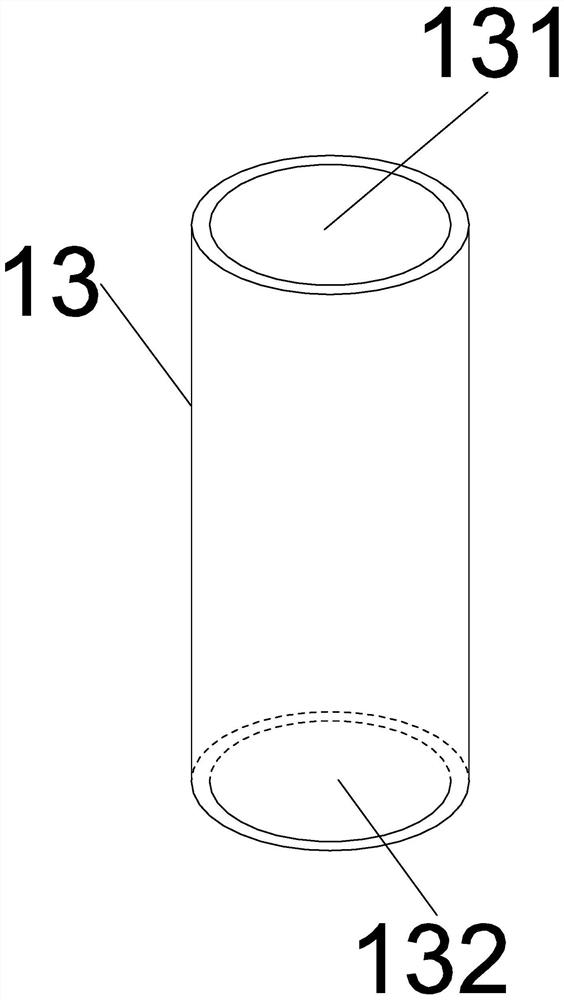

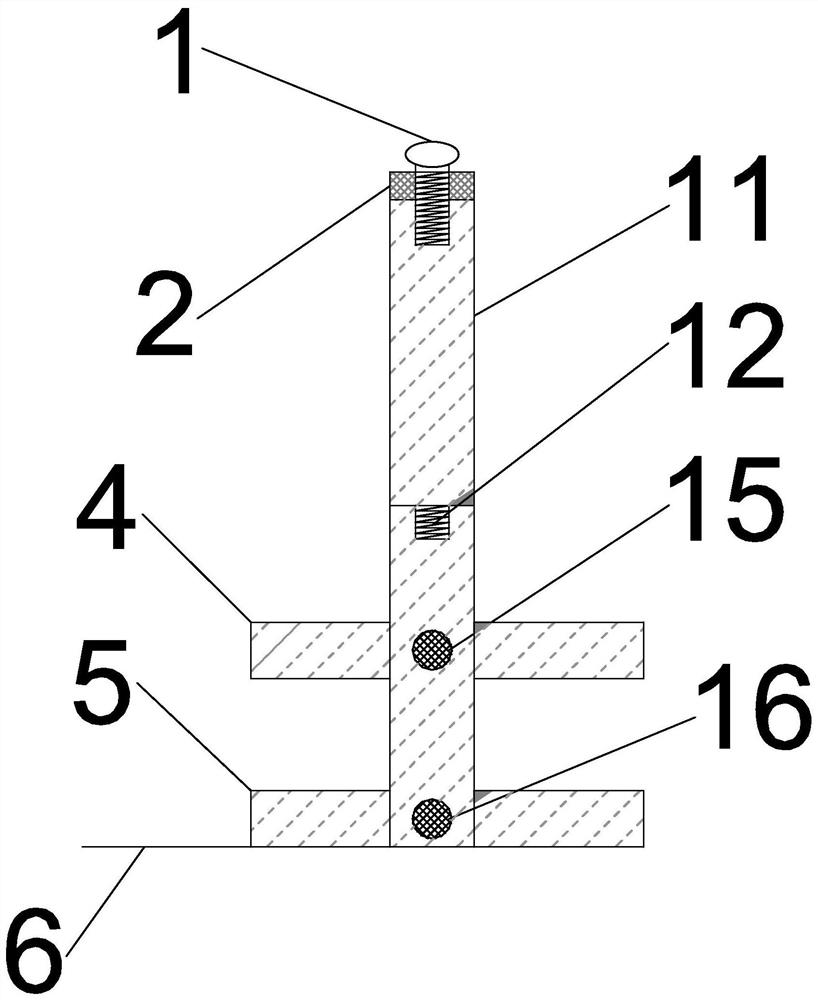

[0032] like Figure 1 to Figure 6 As shown, a sampling and curing system for undisturbed sand includes a sampling bracket, a sampling pipe 13, a permeation cylinder 3, a storage cylinder 19 and a curing oven, which is used for curing undisturbed sand samples. The top of the sampling tube 13 has a top nozzle 131, and the bottom of the sampling tube 13 has a bottom nozzle 132. The sampling support includes a pole assembly and a U-shaped clamp assembly installed on the pole assembly. The pole assembly includes two mutually parallel Upright poles 11, bearing steel sheets 6 are fixedly connected between the bottoms of the two upright poles 11, crossbars 2 are connected by screws 1 between the tops of the two upright poles 11, and the sampling tube 13 is matched and assembled on the U-shaped clamp assembly. A through-hole bracket 7 is installed inside the permeation cylinder 3 , and the sampling bracket and the sampling tube 13 are placed on the through-hole bracket 7 in the permeat...

Embodiment 1

[0044] A kind of sampling curing method of undisturbed sandy soil, its method is as follows:

[0045] A. According to figure 1 Connect the sampling and curing system as shown, select an undisturbed area, dig out the sandy soil on the surface, and then dig down 20-30cm to start sampling. Use a scraper to scrape the surface of the sand, vertically and slowly press the nozzle 132 at the bottom of the sampling tube 13 into the sand carefully, take the original sand sample 14 from the sampling tube 13, and the pressing depth is the sampling height, and the pressing depth is specific according to the test. Ask to be sure.

[0046] B. Gently scrape off the sand around the sampling tube 13 with a thin blade knife, place the bearing steel sheet 6 of the sampling bracket directly below the bottom nozzle 132, and then attach the bearing steel sheet 6 at the bottom of the sampling bracket to the sampling tube 13 Slowly push the bottom of the sampling bracket horizontally so that the bea...

Embodiment 2

[0051] A kind of sampling curing method of undisturbed sandy soil, its method is as follows:

[0052] A. Select an undisturbed area, dig out the surface sand, and then dig down 20-30cm to start sampling. Use a scraper to scrape the surface of the sand and soil, vertically and slowly press the bottom nozzle 132 of the sampling tube 13 into the sand and soil (the wall thickness of the sampling tube 13 is 0.5mm, and the internal diameter of the sampling tube 13 is 59mm), the sampling tube 13 Take the undisturbed sand sample 14 (silty fine sand), and the indentation depth is 3-4cm.

[0053] B. Scrape away the sand and soil around the sampling pipe 13 gently with a sheet knife, and place the bearing steel sheet 6 of the sampling support (the bearing steel sheet 6 is a stainless steel 304 thin steel sheet with a thickness of 0.2 mm) directly below the bottom nozzle 132 , and then the bearing steel sheet 6 at the bottom of the sampling bracket is closely attached to the bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com