Glue connecting dynamic shear testing device and method based on Hopkinson pressure bar system

A technology of Hopkinson compression bar and testing device, which is applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., which can solve the problems of testing method and result error, complex device, etc., and achieve reasonable and reliable design , Guaranteed accuracy, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

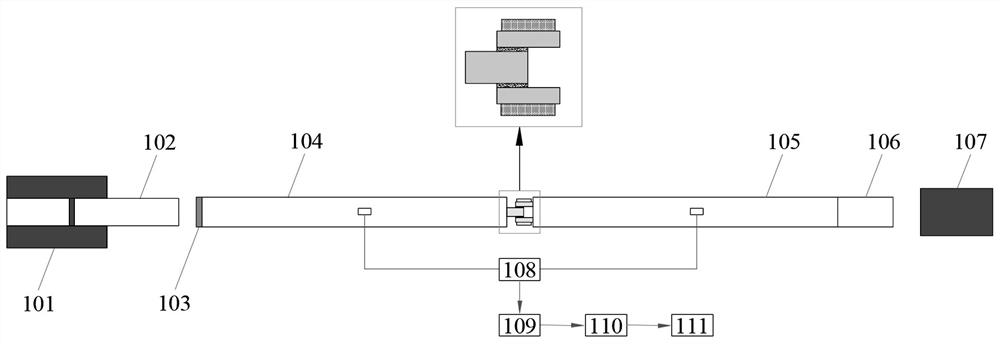

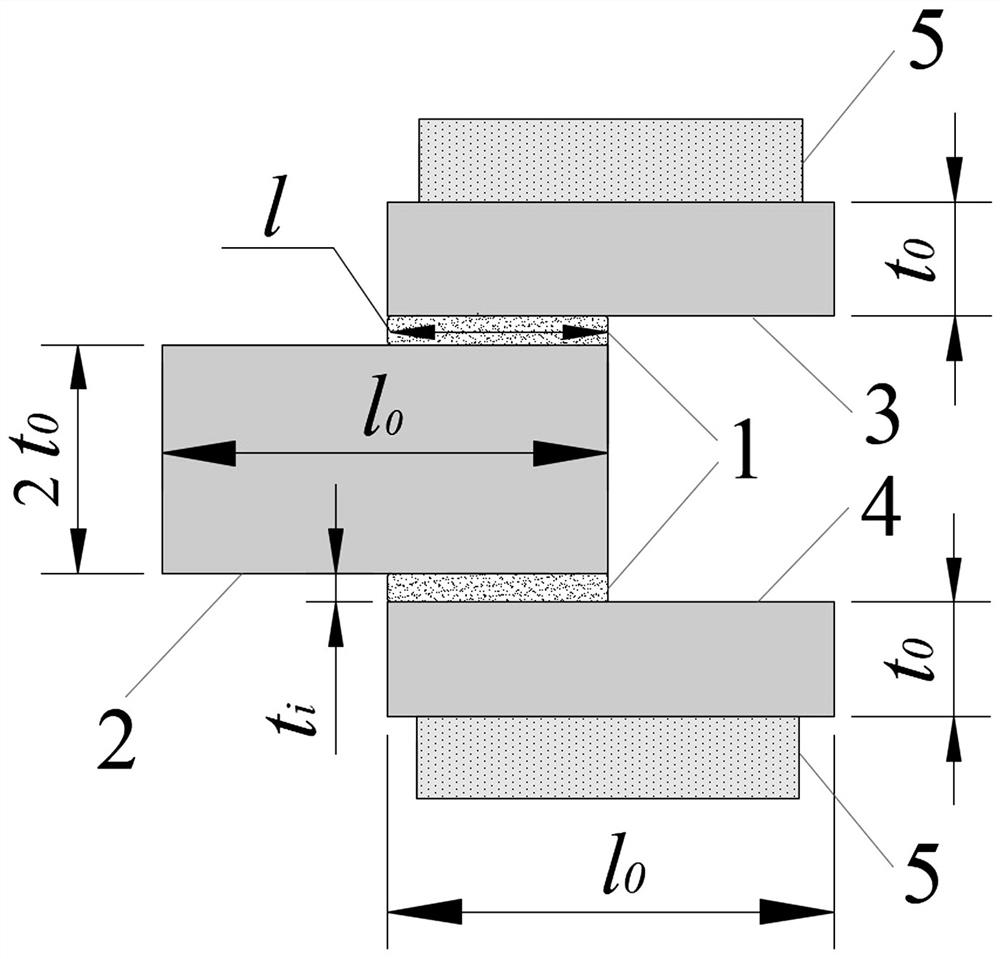

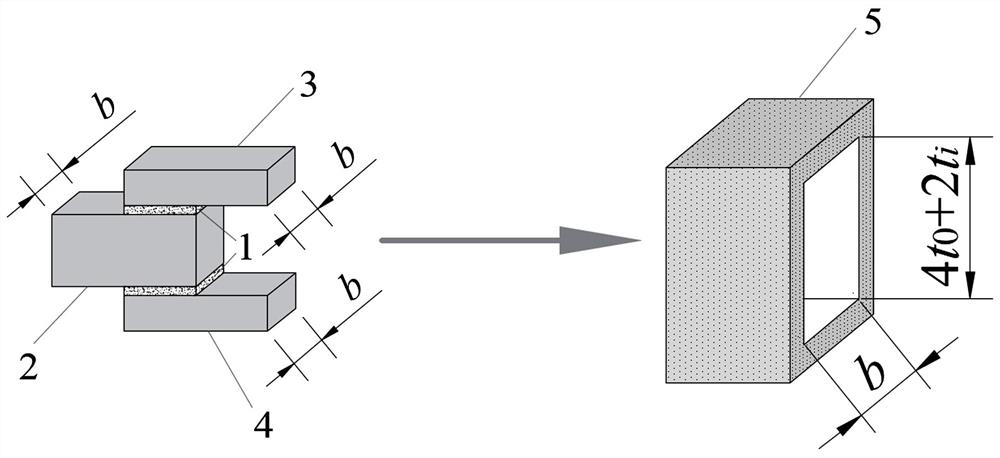

[0022] A dynamic shear test device for glued joints based on the Hopkinson pressure bar system, such as Figure 1 ~ Figure 3 Shown: including adhesive joints and Hopkinson pressure bar system; said adhesive joints include three lap joints, two layers of adhesive layers 1 and a polytetrafluoroethylene sleeve 5, and the three lap joints are lap joints Part I2, lapping part II3 and lapping part III4, the three lapping parts and the two layers of adhesive layer 1 are interconnected by double lapping. The double lapping method is: lapping part I2 is located between lapping part II3 and In the middle of the lap joint III4, the front and rear sides of the lap joint I2, the lap joint II3 and the lap joint III4 are flush, and the left and right sides of the lap joint I2 and the lap joint II3 are misaligned and connected by the glue layer 1, The bridging piece I2 and the bridging piece...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap