Photoetching mask for photoetching alignment of small-size patterns, and chip photoetching method

A technology of lithography alignment and lithography plate, which is applied in the field of photoelectric detection, can solve the problems that it is difficult for human eyes to recognize small-sized graphics, and it is impossible to prepare chips with small-sized graphics, and achieve the effect of saving available space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

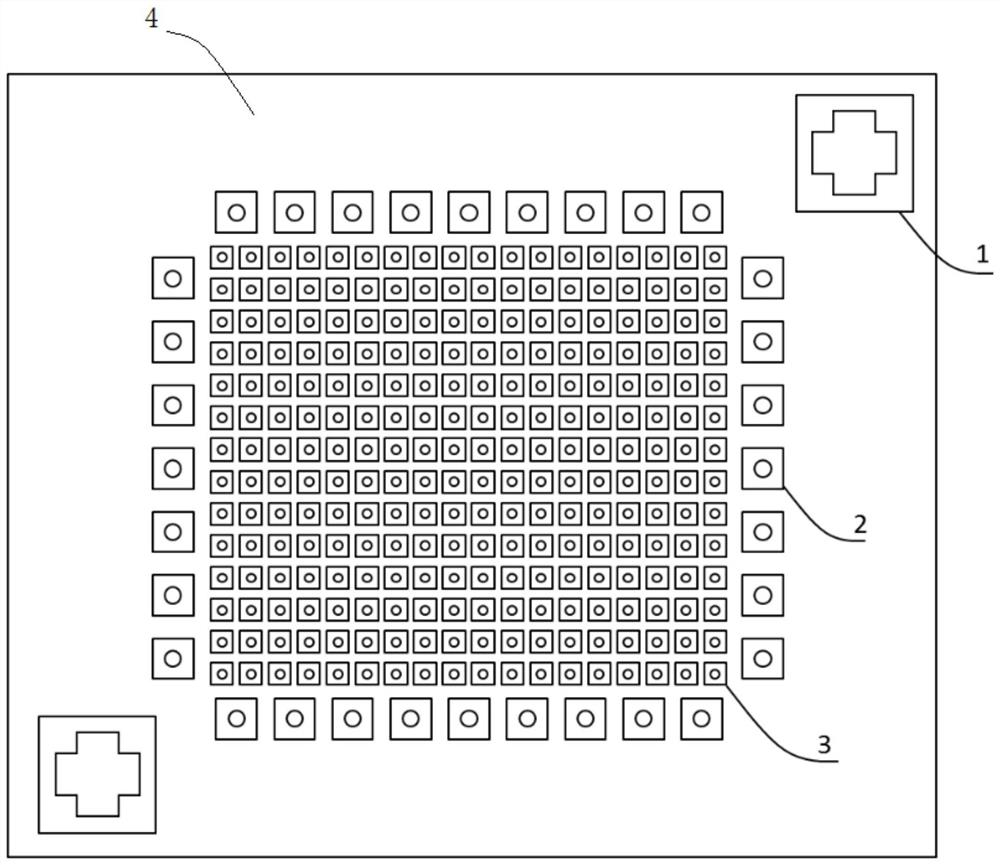

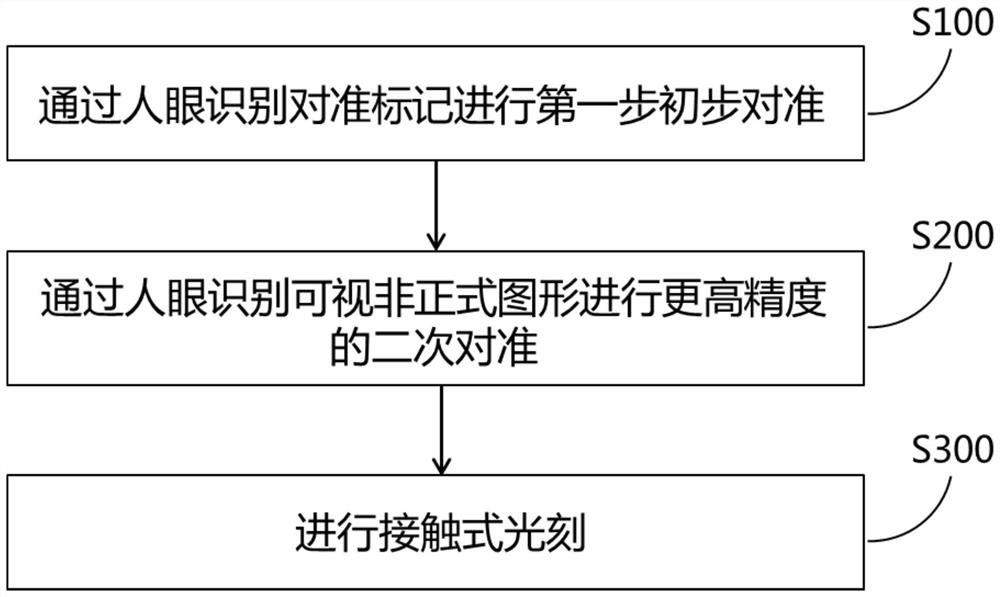

[0052] The photoresist plate used for photolithographic alignment of small-scale patterns in the embodiment of the present invention is suitable for photolithography of a chip. like figure 1 As shown, the photolithography plate includes three main parts: alignment marks 1, visible informal graphics 2, and invisible formal graphics 3. The size of the alignment mark 1 is designed to be very obvious and clearly visible according to the size of the chip and the actual available space, the shape is any complementary figure, the number is 2-4, and it is located at the four corners of the body 4 for preliminary alignment of photolithography; The size of the visible informal figure 2 is the smallest size that can be clearly recognized by the human eye under the field of view of the contact lithography machine used, and the shape is the invisible formal figure 3. Array form, and there is a corresponding law with the arrangement of the formal pattern, which is used for the final high-p...

Embodiment 2

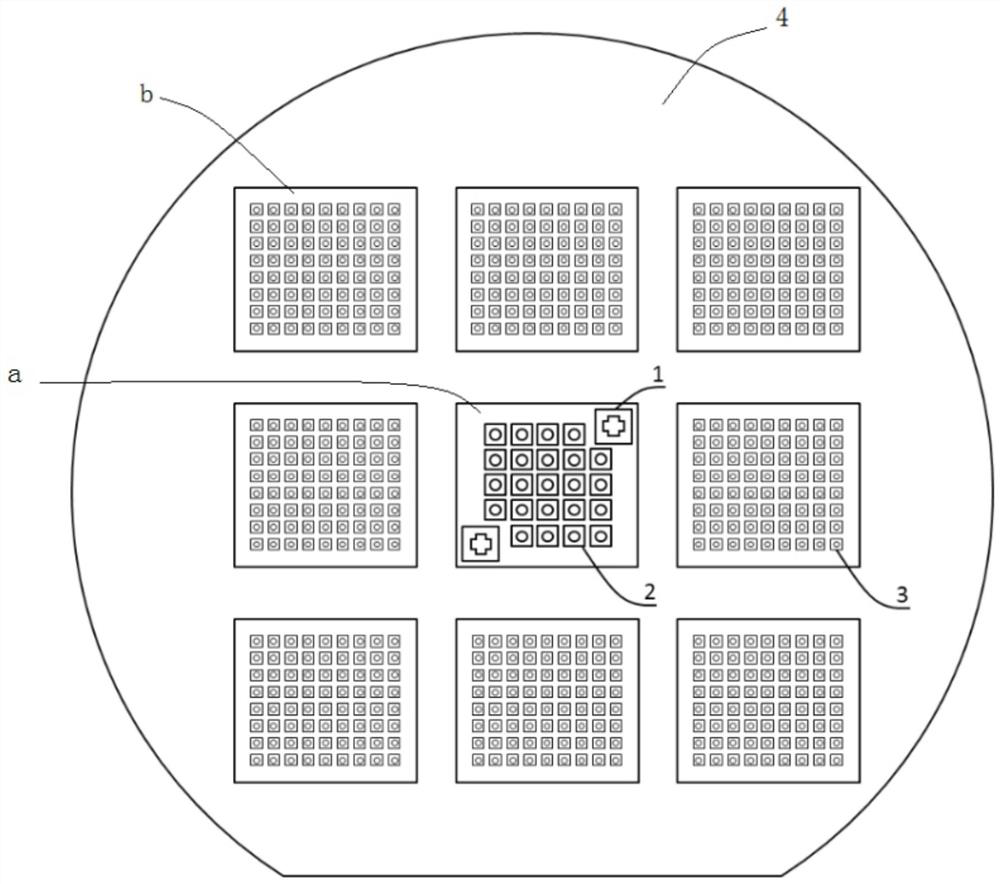

[0059] The photoresist plate used for photolithographic alignment of small-scale patterns in the embodiment of the present invention is suitable for photolithography of multiple chips at the same time. like figure 2 As shown, the photolithographic plate includes two main parts: the first area a and the second area b, wherein the size of the first area a is the same as that of the second area b, and the number and position can be determined according to the number of the second area b Reasonable adjustments are made; the size of the invisible official pattern 3 in the second region b is within the exposure accuracy range of the contact lithography machine used, but cannot be recognized by human eyes.

[0060] The first area a comprises two main parts: alignment marks 1 and visible informal graphics 2 . The size of the alignment mark 1 is designed to be very obvious and clearly visible according to the size of the chip and the actual available space. The shape is any complemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com