Novel intelligent sole pasting production line

A production line and bottoming technology, used in footwear, bonded shoe parts, apparel, etc., can solve problems such as low production efficiency and quality, slow connection, and inability to meet customer processing requirements, and achieve improved production efficiency and quality. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

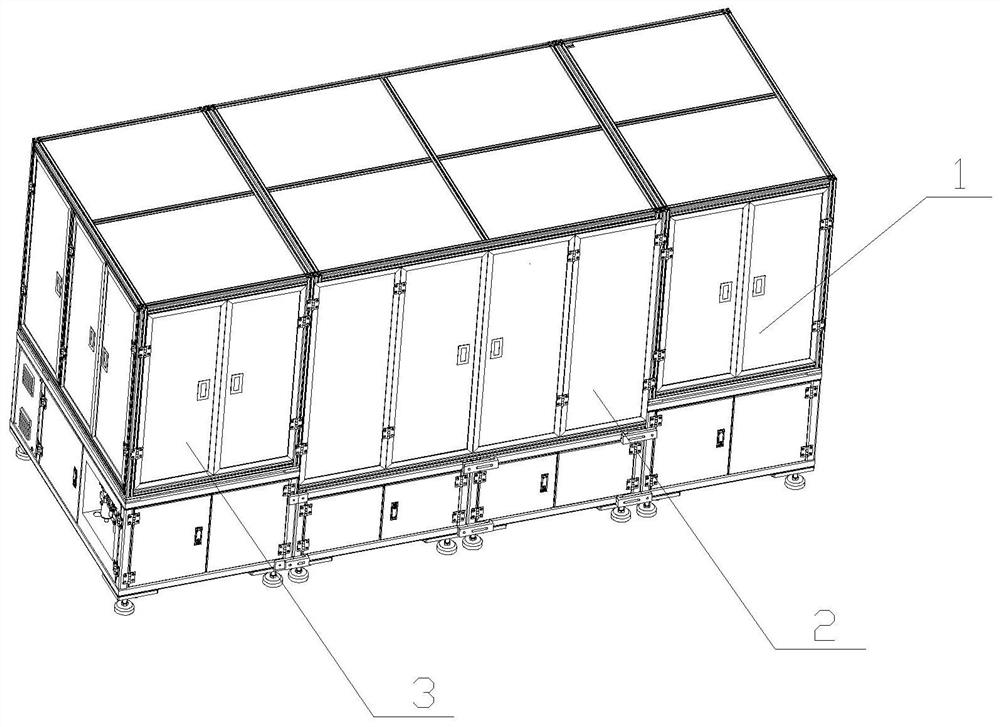

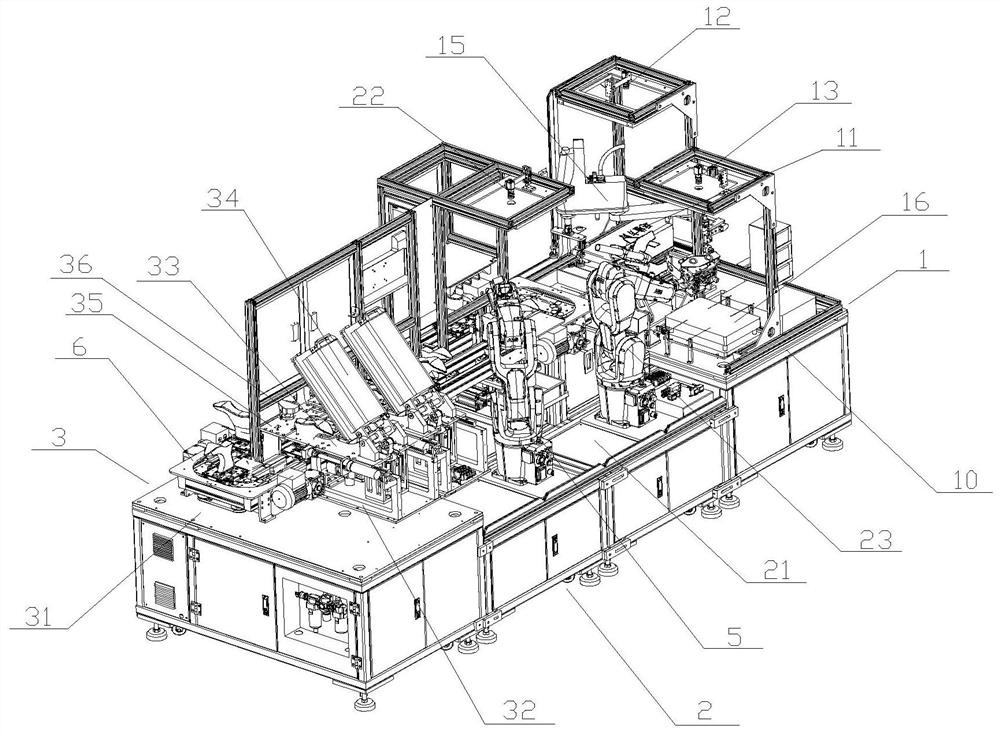

[0038] refer to Figure 1 to Figure 17 , this embodiment provides a new type of intelligent bottom sticking production line, including a protective frame, a sole transmission and positioning module 1 installed inside the protective frame and sequentially connected, a bottom sticking module 2 and a pressure maintaining module 3;

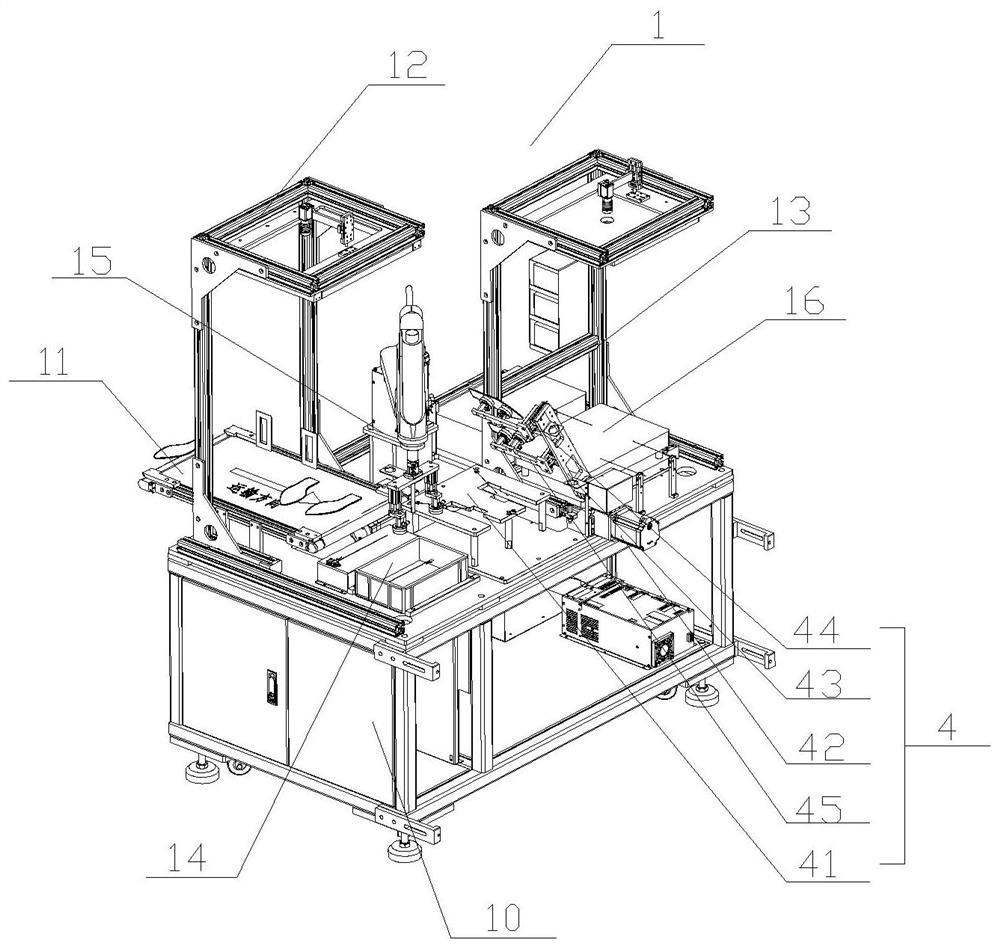

[0039] The sole positioning module 1 includes a frame 10, a transmission unit 11 installed on the frame 10, a transfer mechanism 15, a turnover mechanism 4 and a visual identification mechanism 13, the transmission unit 11 is used to transfer the sole to the first position, and the transfer mechanism 15 is installed on the right side of the transmission unit 11 and the sole is moved to the turning mechanism 4. The turning mechanism 4 reverses the sole and places the turned sole on the platform 16 below the visual recognition mechanism 13. The visual recognition mechanism 13 can Identify the shoe size of the shoe sole, the transmission unit 11 is a syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com