Double-layer film actuator and preparation method thereof

A double-layer film and actuator technology, applied in coatings, instruments, electrical solid devices, etc., can solve the problems of inability to realize large-area preparation, inability to directional growth of transition metal oxides, and limited ultra-thin flexible metal substrate manufacturing process and cost issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Disperse commercial magnesium oxide nanoparticles in anhydrous ethanol solvent, and ultrasonically disperse to obtain a 20 mg / mL suspension.

[0028] (2) Scrape-coat the suspension solution prepared in step (1) on the surface of the polystyrene film substrate, and the coating amount is 0.05mg / cm 2 , and then dried at 60 degrees Celsius.

[0029] (3) Immerse the composite film prepared in step (2) in solutions with a metal ion concentration of 0.05M and different molar ratios (see Table 1), and the reaction time at room temperature is 1 hour.

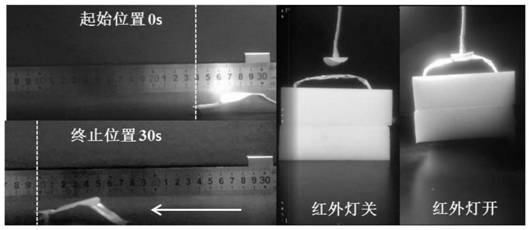

[0030] (4) Take out the film in step (3), wash and dry to obtain the target double-layer film, and adopt infrared light irradiation to control the change of environmental humidity, and observe the actuation of the target film.

[0031] Table 1

[0032]

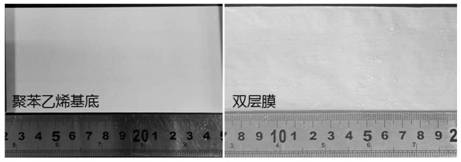

[0033] pass figure 1 The digital photo can clearly see that the area is 5*13cm 2 A brown-yellow substance uniformly grew on the surface of the polystyrene film.

[003...

Embodiment 2

[0038] (1) Disperse commercial magnesium oxide nanoparticles in anhydrous ethanol solvent, and ultrasonically disperse to obtain a 20 mg / mL suspension.

[0039] (2) Scrape-coat the suspension solution prepared in step (1) on the surface of the polystyrene film substrate, and the coating amount is 0.05mg / cm 2 , and then dried at 60 degrees Celsius.

[0040] (3) Immerse the composite film prepared in step (2) in a zinc acetate solution, the metal ion concentration is 0.05M, and the reaction time at room temperature is 1 hour.

[0041] (4) Take out the film in step (3), wash and dry to obtain the target double-layer film, and adopt infrared light irradiation to control the change of environmental humidity, and observe the actuation of the target film.

[0042] Depend on Figure 5 It can be seen that under this growth condition, the bilayer film has the ability to deform under the action of infrared light.

Embodiment 3

[0044] (1) Disperse commercial magnesium oxide nanoparticles in anhydrous ethanol solvent, and ultrasonically disperse to obtain a 5 mg / mL suspension.

[0045] (2) The suspension solution prepared in step (1) is loaded on the surface of the polystyrene microporous film substrate by vacuum filtration, and the coating amount is 0.05 mg / cm2 , and then dried at 60 degrees Celsius.

[0046] (3) Immerse the composite film prepared in step (2) in nickel nitrate solution, the metal ion concentration is 0.05M, and the reaction time at room temperature is 1 hour.

[0047] (4) Take out the film in step (3), wash and dry to obtain the target double-layer film, and adopt infrared light irradiation to control the change of environmental humidity, and observe the actuation of the target film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com