Coal ramming mehtod and apparatus for horizontal coke furnace

A coking oven and tamping coal technology, which is applied in the field of coking oven tamping coal, can solve the problems of affecting the quality of coke products, short carbonization chamber, and large width of tamping coal tank, so as to achieve high tamping efficiency, uniform coal distribution, Good quality tamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

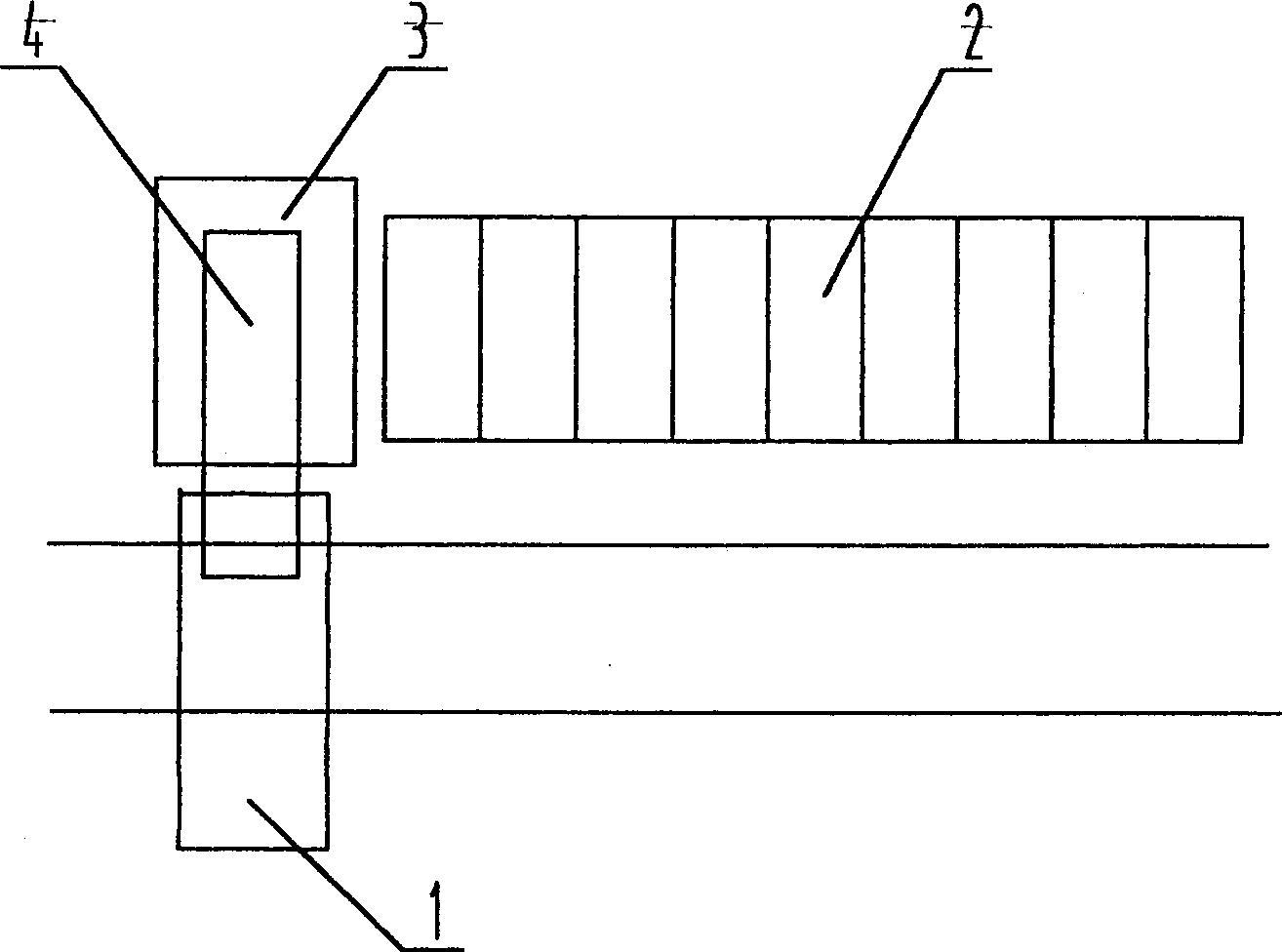

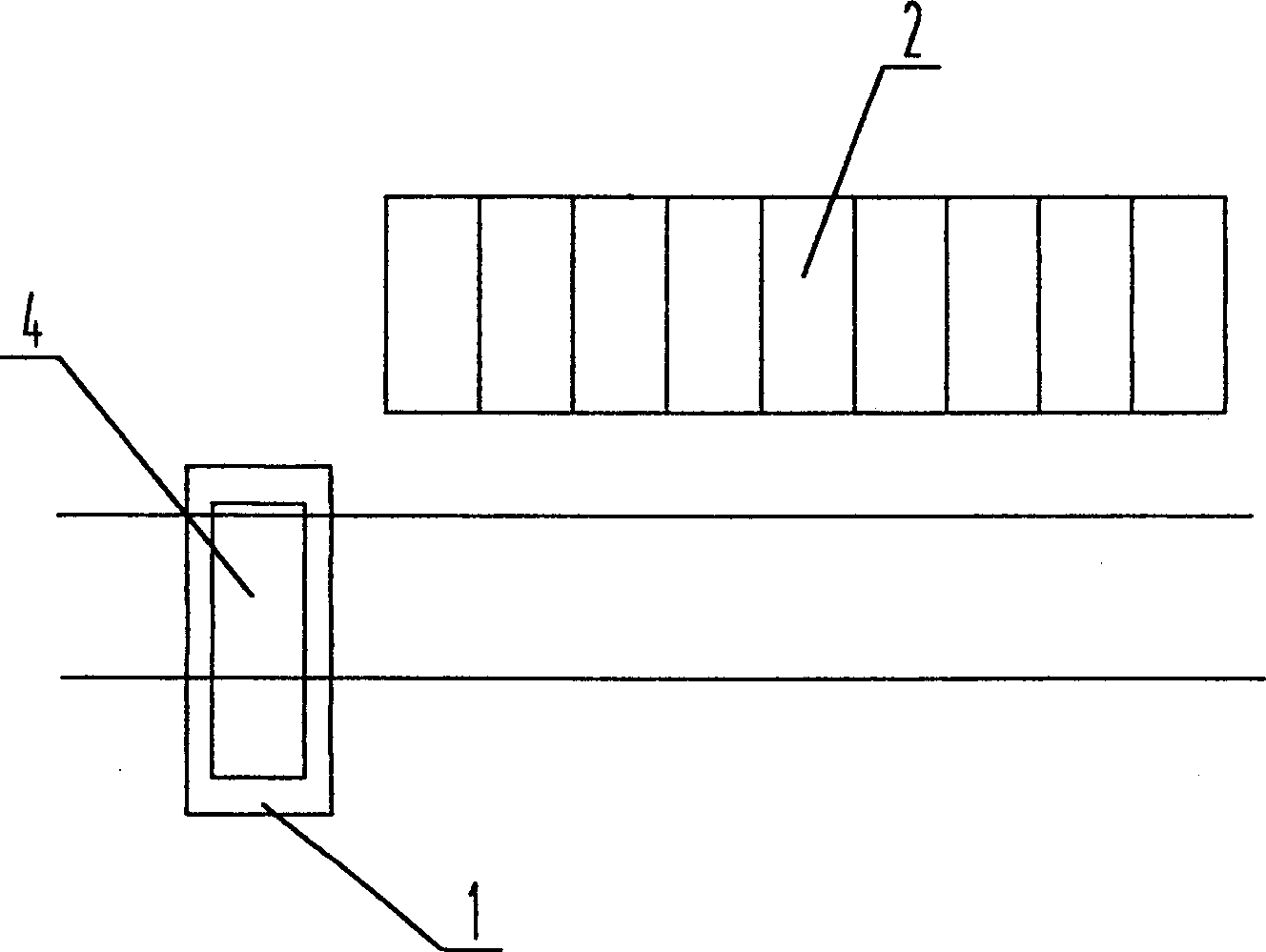

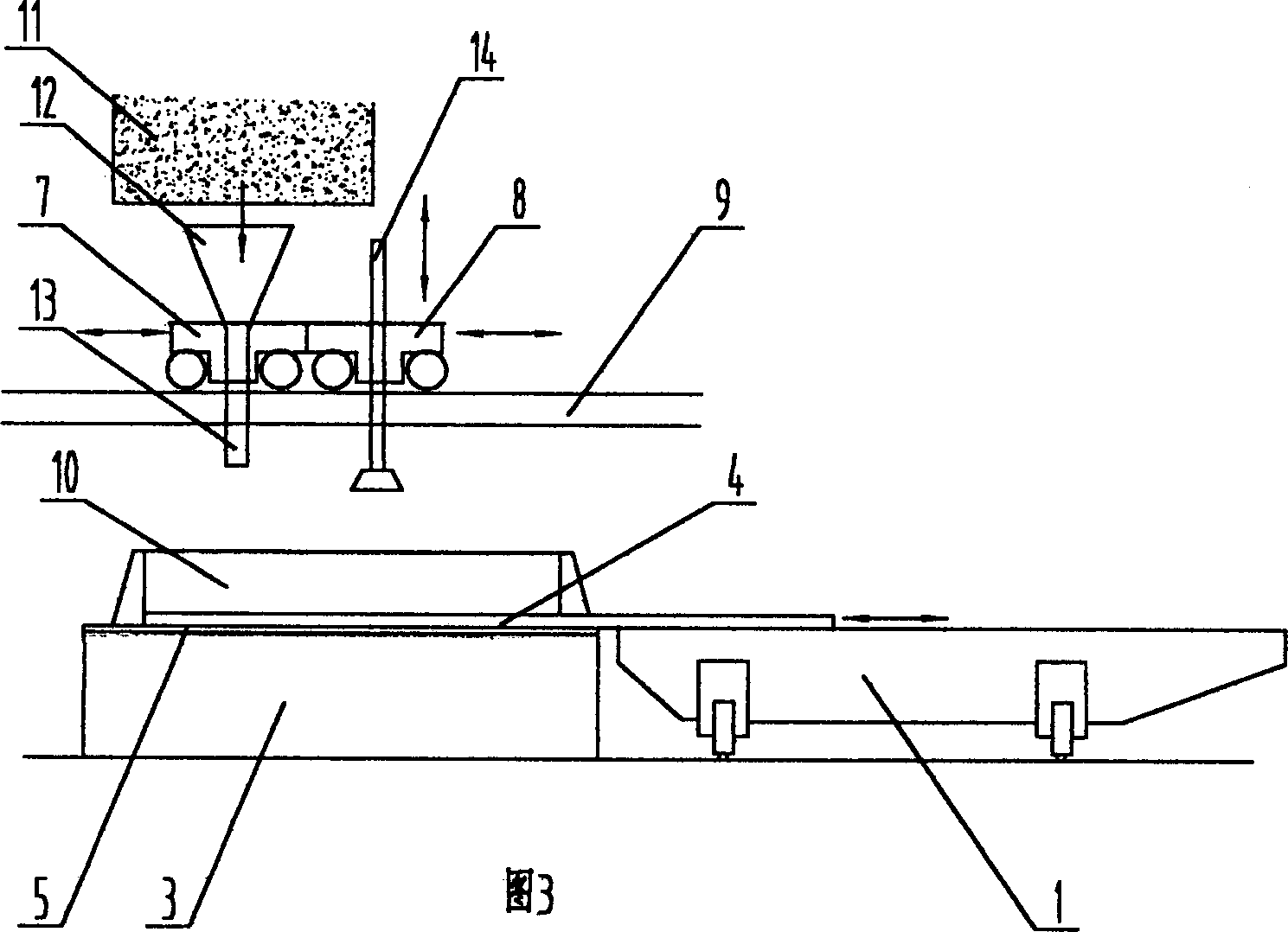

[0032] Such as figure 1 , shown in Fig. 3, a kind of method of horizontal coke oven tamping coal, its step is:

[0033] 1) The coal loading car 1, together with the coal support plate 4 above, moves from the front of the horizontal coke oven 2 to the tamping position;

[0034] 2) Pull the coal support plate 4 on the coal loading car 1 onto the tamping platform 3;

[0035] 3) Tamping molds 10 are set on the four sides of the coal supporting plate 4, and locked;

[0036] 4) Load the loose coal into the coal hopper 12 of the coal distribution trolley 7 from the coal bunker 11;

[0037] 5) Start the coal distributing trolley 7 that is positioned above the tamping mold 10 and can move along the track beam 9 installed in the length direction of the tamping mold, and simultaneously open the coal distributing port 13 to spread loose coal into the tamping mold;

[0038] 6) drive the tamping trolley 8 positioned at the top of the tamping mold 10, which can move along the track beam 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com