A kind of sugarcane cutting equipment

A technology of cutting and equipment, applied in agricultural machinery and equipment, metal processing, energy-saving measures, etc., can solve the problems of low ease of use, labor-intensive, difficult to improve production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

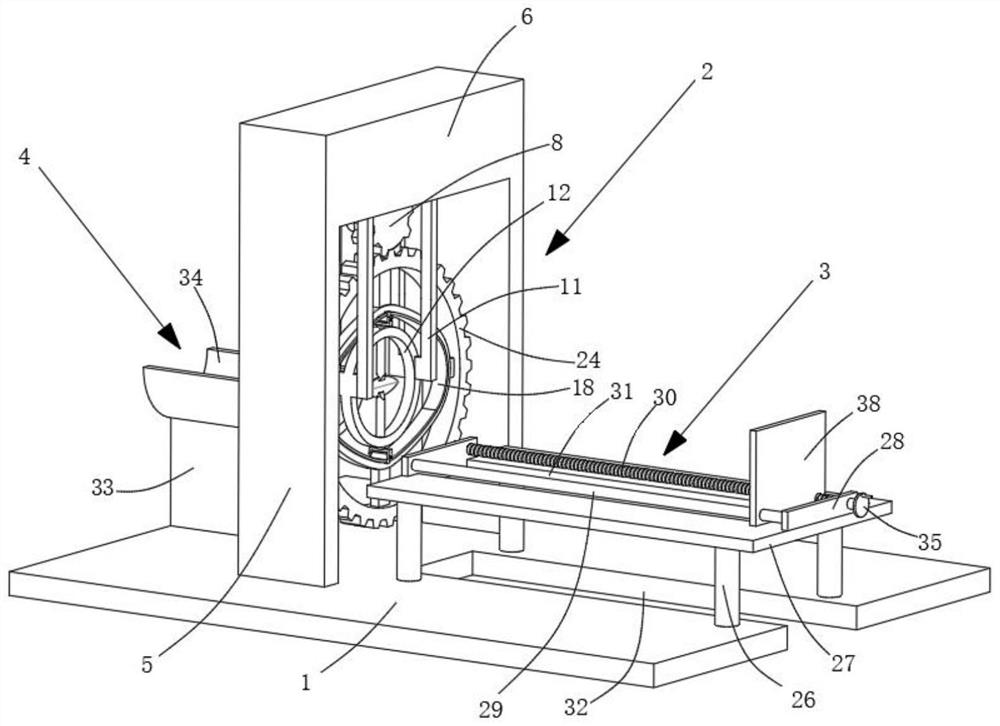

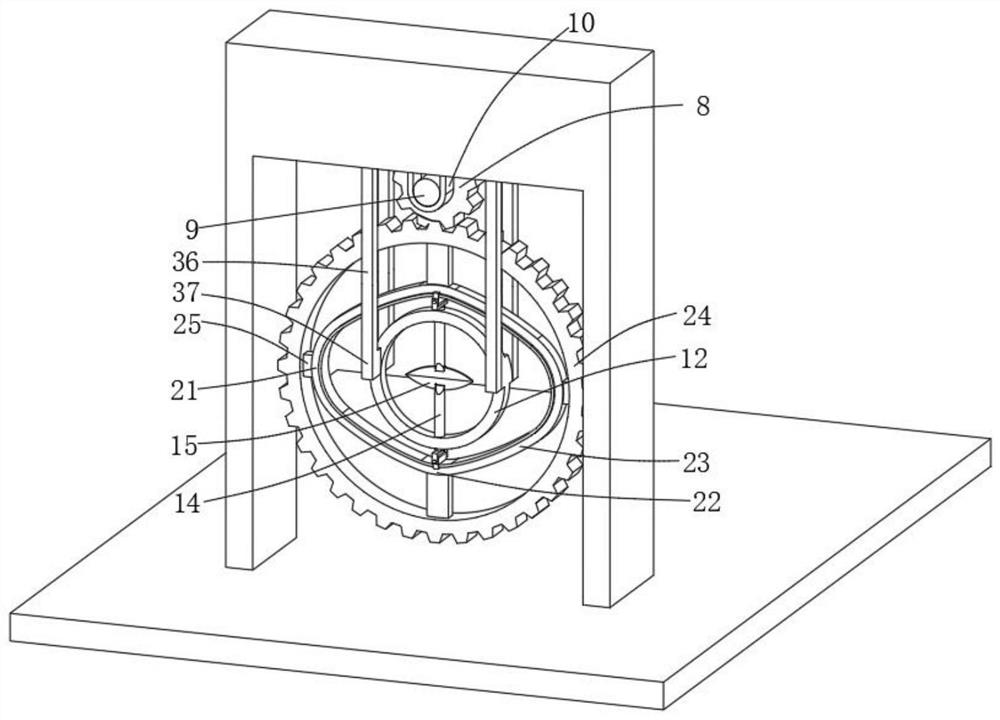

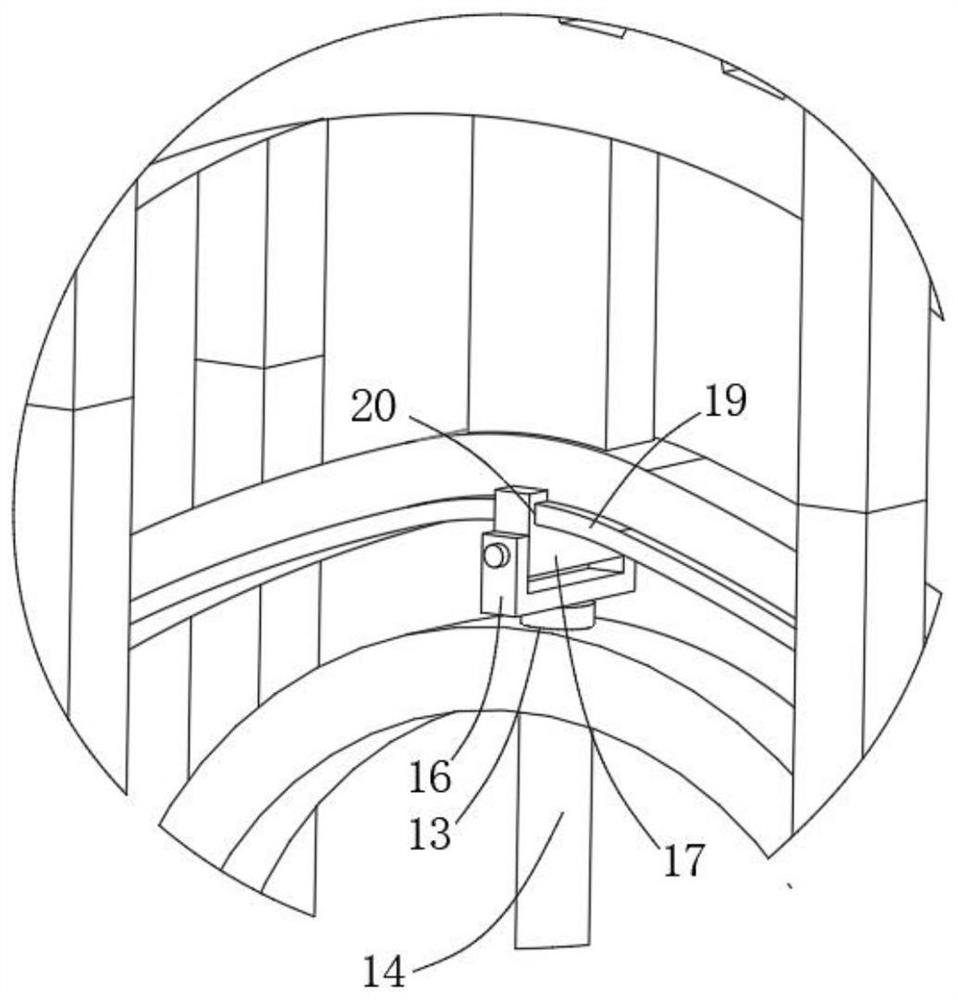

[0022] Example: a sugarcane cutting device, as attached figure 1 As shown in the figure, it includes a base 1, and the base 1 is provided with a segment cutting mechanism 2, as shown in the attached figure 2 and attached Figure 4 As shown, both sides of the segment-cutting mechanism 2 are respectively provided with a length adjusting mechanism 3 and a support plate 4, and the segment-cutting mechanism 2 includes a motor support rod 5 symmetrically arranged on the base 1, and the ends of the motor support rods 5 are set together. There is a motor casing 6, and a rotating motor 7 is arranged in the motor casing 6. The rotating motor 7 can flexibly adjust the speed according to the needs, thereby adjusting the cutting speed of the sugarcane segment. The output end of the rotating motor 7 is provided with a transmission gear 8 below, and the transmission gear 8 There is a transmission shaft 9 at the center of the circle, and the transmission shaft 9 and the output end of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com