Movable wharf grab bucket hoisting hopper

A hopper, mobile technology, used in loading/unloading, conveyor, transportation and packaging, etc., can solve the problems of polluting the surrounding environment and flying dust, and achieve the effect of preventing dust overflow, improving efficiency and improving the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

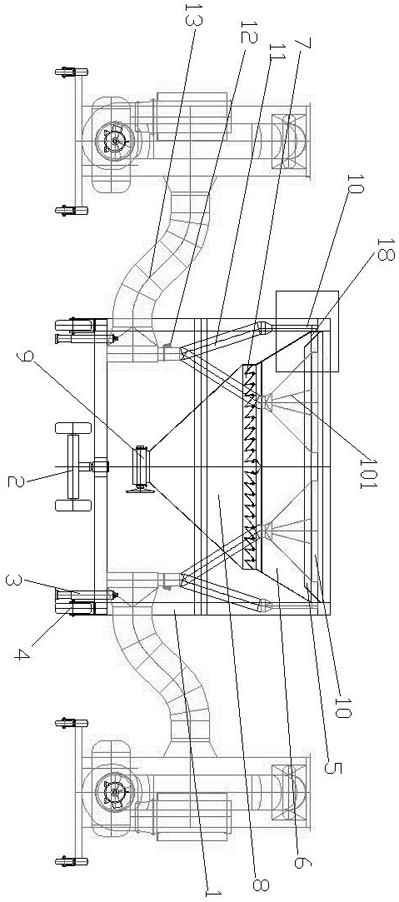

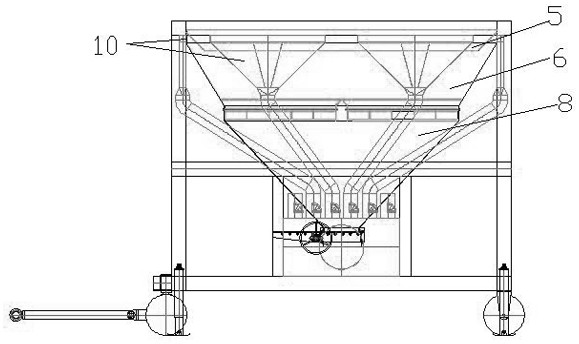

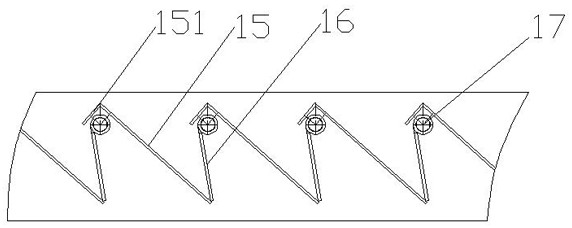

[0028] As shown in the figure, a mobile dock grab lifting hopper of the present invention includes a first hopper 5, a second hopper 6 and a third hopper 8 arranged in sequence, and the second hopper 6 and the first hopper The three hoppers 8 are connected through the dust suppression grid 7, and the dust suppression grid 7 includes a fixed drip plate 15 fixed on the third hopper 8 and a movable drip plate 16 connected with the third hopper through a rotating shaft 17. The fixed dripping plate 15 is arranged obliquely, and one end of the movable dripping plate 16 is connected with the rotating shaft, and the other end can contact the fixed dripping plate 15 .

[0029] When in use, due to the effect of gravity, the movable dripping plate 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com