Bionic composite board with sine ripple structure and vibration isolation table

A composite board and corrugated board technology, applied in the field of composite boards, can solve the problems of poor energy absorption effect of sandwich panels and achieve the effect of improving energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

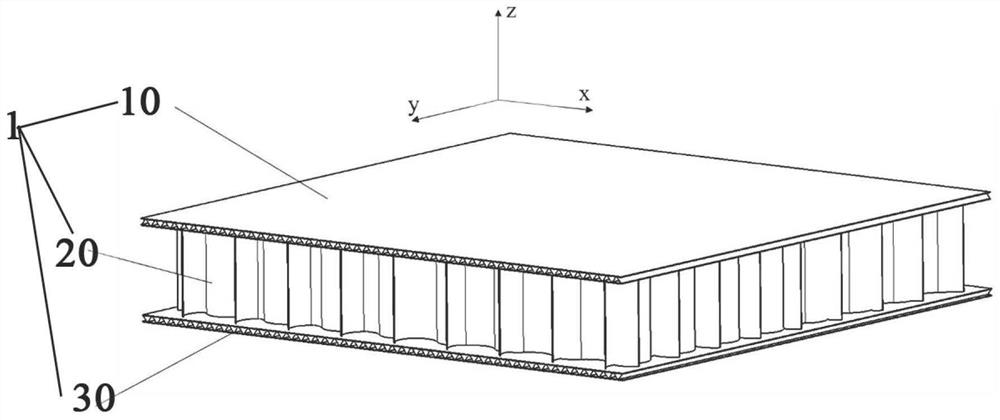

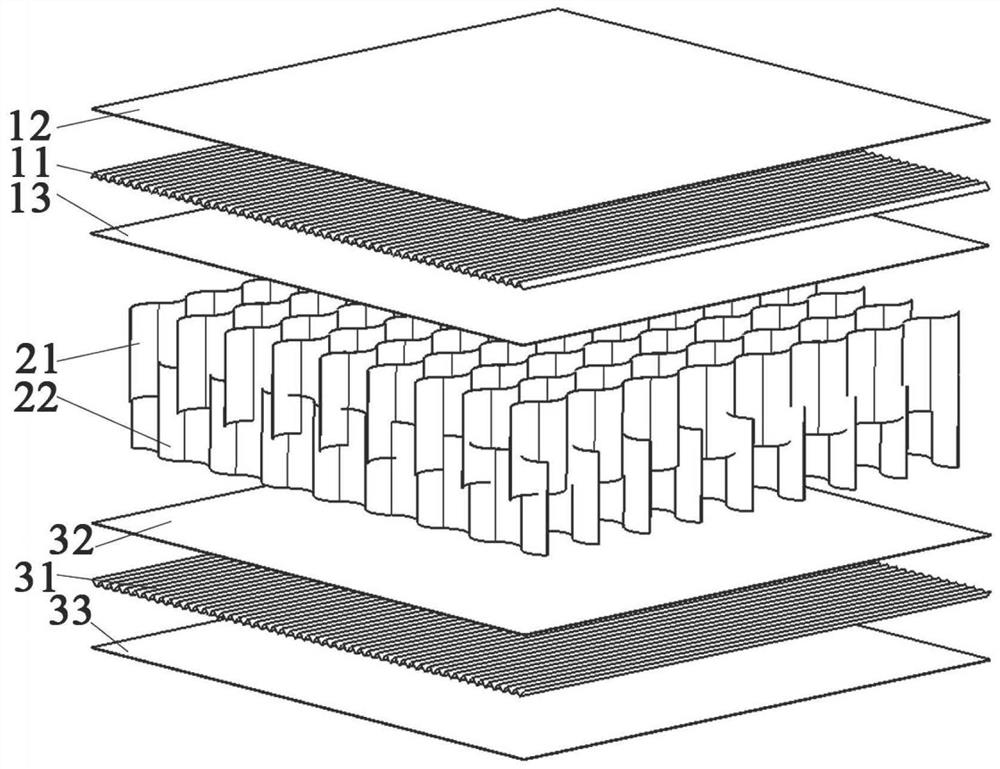

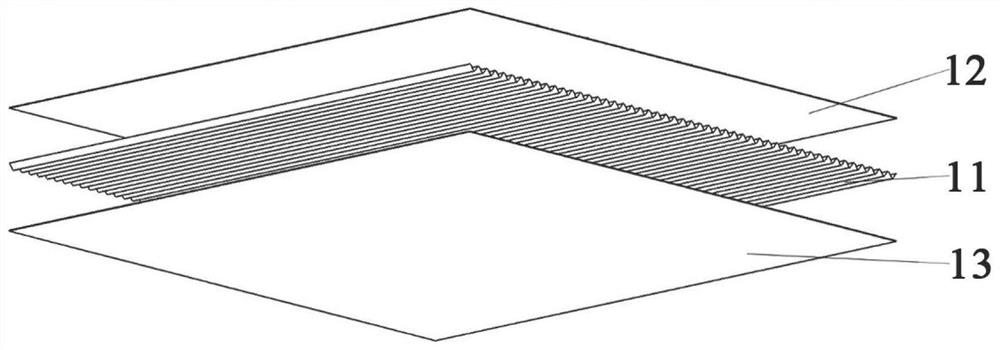

[0089] Such as figure 1 and figure 2 As shown, the upper corrugated board assembly 10, the corrugated honeycomb sandwich assembly 20 and the lower corrugated board assembly 30 of the present invention are arranged sequentially from top to bottom, wherein the corrugated honeycomb sandwich assembly 20 has 8-10 first corrugated sheets in the x direction The sheets 21 and 8-10 second corrugated sheets 22 in the y direction are arranged perpendicular to each other, and the corrugated honeycomb sandwich assembly 20 is perpendicular to and fixedly connected to the first lower plate 13 of the upper corrugated plate assembly 10, and is connected to the first lower plate 13 of the lower corrugated plate assembly 30. The two upper plates 32 are vertical and fixed; the longitudinal direction of the third corrugated sheet 11 in the upper corrugated plate assembly 10 is parallel or perpendicular to the direction; the longitudinal direction of the fourth corrugated sheet 31 in the lower cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com