Heat conductive member and method for manufacturing same

A technology of heat-conducting components and manufacturing methods, which is applied in the field of heat-conducting components and their manufacturing, can solve problems such as performance degradation of thermal components, and achieve the effect of reducing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

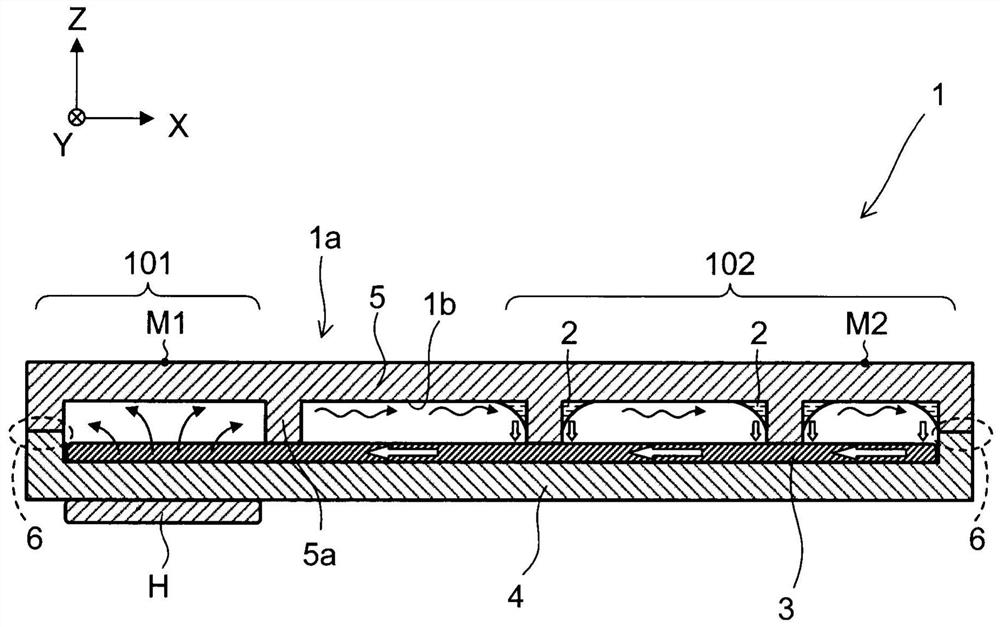

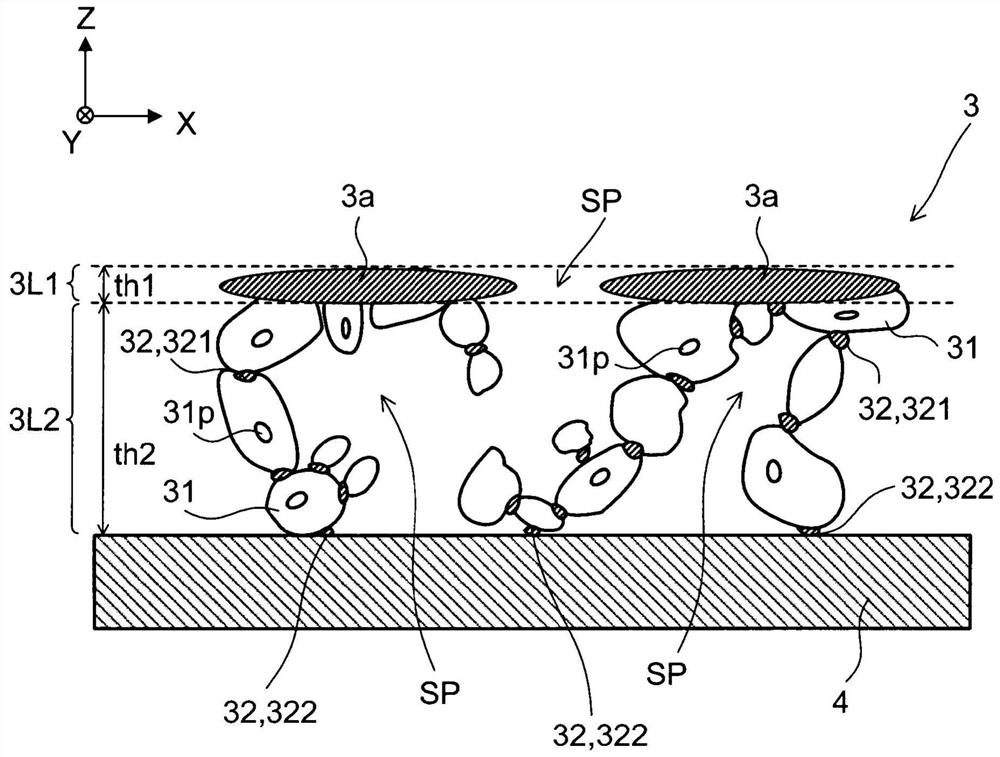

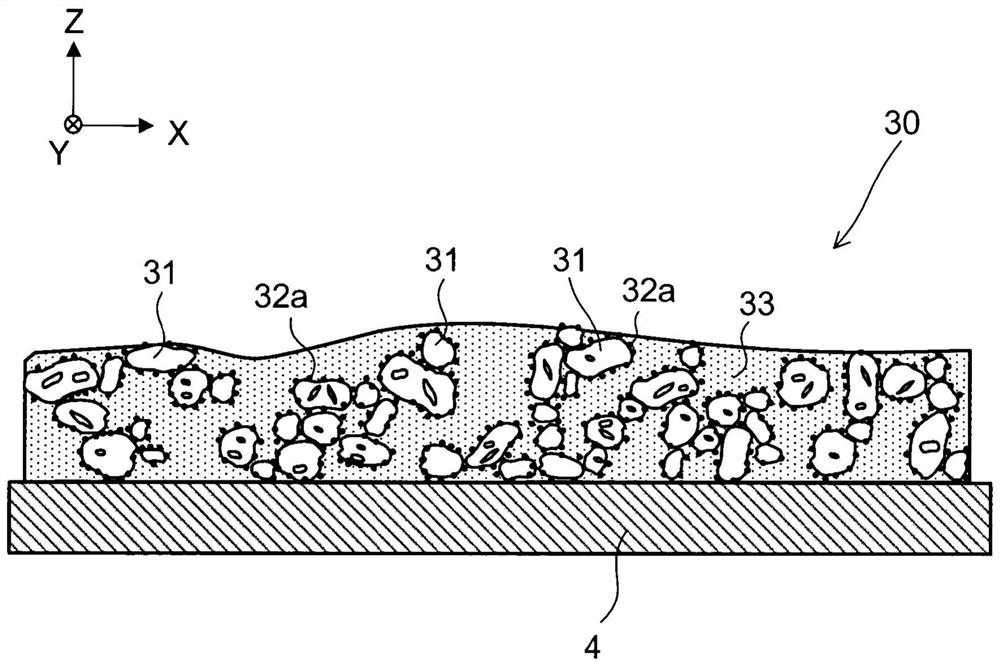

[0018] Hereinafter, a vapor chamber 1 as a heat conduction member according to an exemplary embodiment of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that, in the drawings, the XYZ coordinate system is appropriately shown as a three-dimensional orthogonal coordinate system. In the XYZ coordinate system, the Z-axis direction indicates the vertical direction (that is, the up-down direction), the +Z direction indicates the upper side (opposite the direction of gravity), and the -Z direction indicates the lower side (the direction of gravity). The Z-axis direction may be the facing direction of the first metal plate 4 and the second metal plate 5 described later. The X-axis direction refers to a direction perpendicular to the Z-axis direction, and the one direction and the opposite direction are referred to as +X direction and −X direction, respectively. The Y-axis direction refers to a direction perpendicular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com