Wire stator electrodip paint heating system

A heating system, wire stator technology, applied in electric heating devices, manufacturing stator/rotor bodies, electromechanical devices, etc., can solve the problems of complex automatic heating program design, and achieve low power factor, compensation for reactive power, and reduction of production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

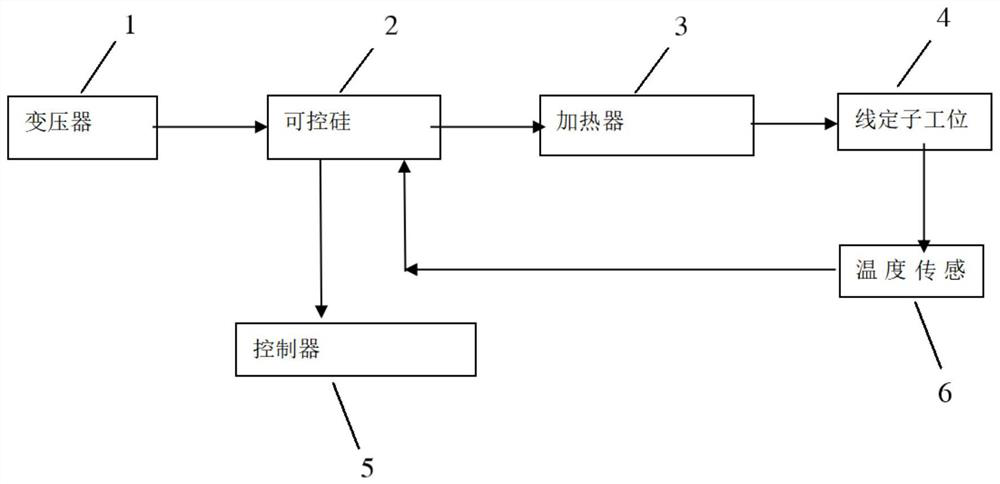

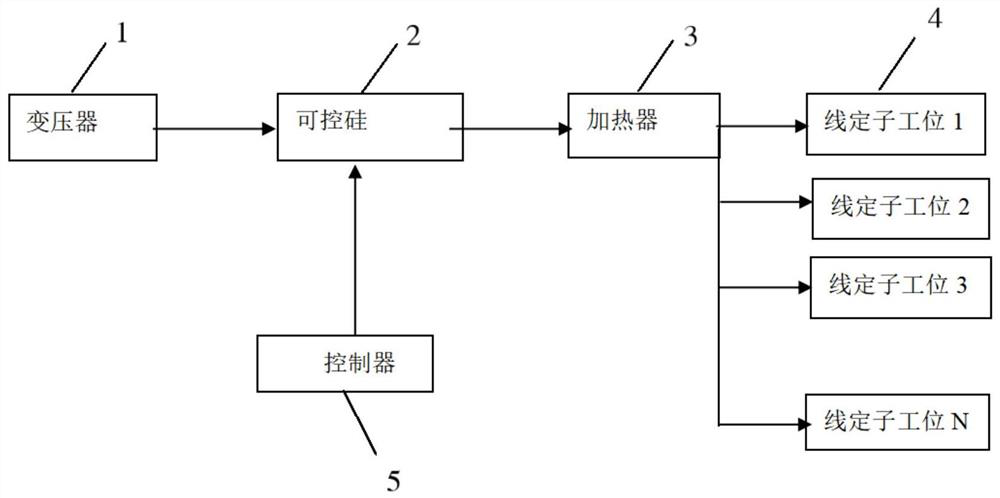

[0026] combined with Figure 1-2 , a wire stator electric varnish heating system in this embodiment includes a transformer 1, a thyristor 2, a heater 3 and a plurality of wire stator stations 4 connected in sequence, the transformer 1 is used to output power, and the The thyristor 2 is used to control the heater 3 to heat the wire stator installed on the wire stator station 4, the thyristor 2 is connected with a controller 5, and the controller 5 is used to store the thyristor 2 pairs of wires Control steps for stator heating. The thyristor 2 records the control steps of heating the wire stator in the controller 5, and the thyristor 2 reads the control program previously stored in the controller 5 and applies it to the heater 3. When there are multiple wires When the stator station is 4, each wire stator station 4 will be loaded with a current that conforms to the control program of the controller 5 to achieve the purpose of temperature control. The program design is very sim...

Embodiment 2

[0028] combined with Figure 1-2 , the wire stator electric dipping paint heating system of this embodiment, compared with the technical solution of embodiment 1, can be improved as follows: the wire stator station 4 is provided with a temperature sensor 6, and the temperature sensor 6 is used to convert the temperature signal Transfer to SCR 2. The embedded temperature sensor 6 on the wire stator feeds back the signal to the thyristor 2, and the thyristor 2 controls the heater 3 after receiving the signal, so as to achieve the purpose of heating the wire stator.

Embodiment 3

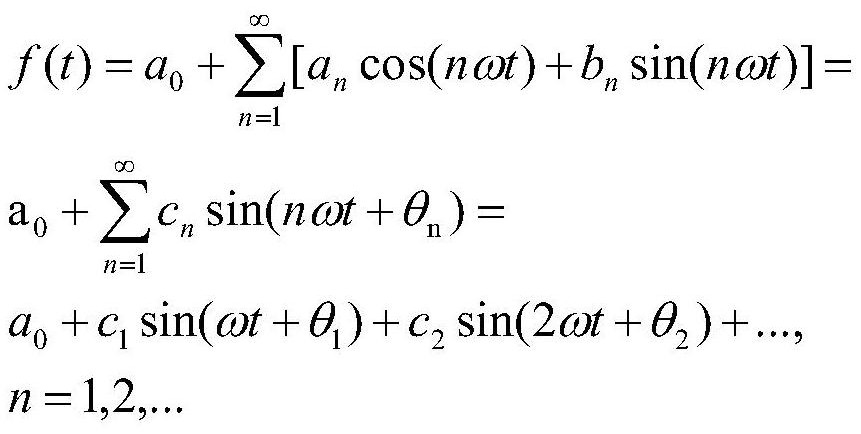

[0030] combined with Figure 1-2 Compared with the technical solution of Embodiment 1 or 2, the wire stator electric varnish heating system of this embodiment can be improved as follows: a filter is also included, and the filter is used for harmonic compensation of the transformer 1 . The filter effectively filters out the frequency point of a specific frequency in the power line or frequencies other than this frequency point to obtain a power signal of a specific frequency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com