Cigarette filter stick packaging paper tape center line glue coating device and method

A technology of paper tape and filter rod, which is applied to the surface coating liquid device, spray device, coating, etc., which can solve the problems of difficult adjustment of relative position, unstable adhesive force, glue penetration, etc., and achieves favorable operation and maintenance, uniform thickness of gluing, and unimpeded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

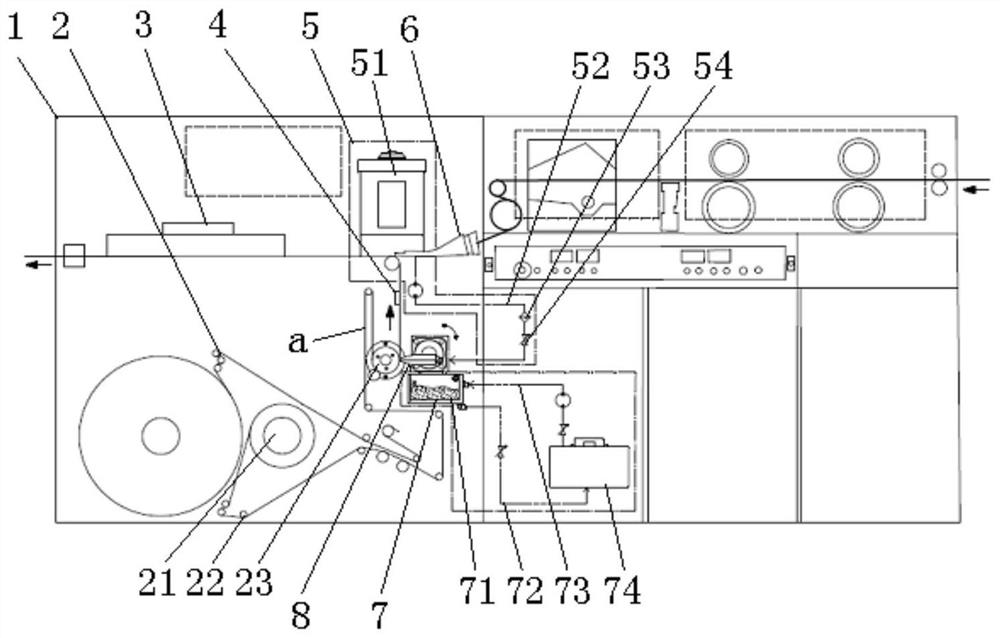

[0052] The device for coating and gluing the center line of the cigarette filter stick wrapping paper tape provided by the present invention includes:

[0053] The glue supply mechanism 5 is used to provide the glue used for gluing on the middle line of the cigarette filter rod wrapping paper tape;

[0054] Wrapping paper tape supply mechanism 2, used to provide the wrapping paper tape for gluing;

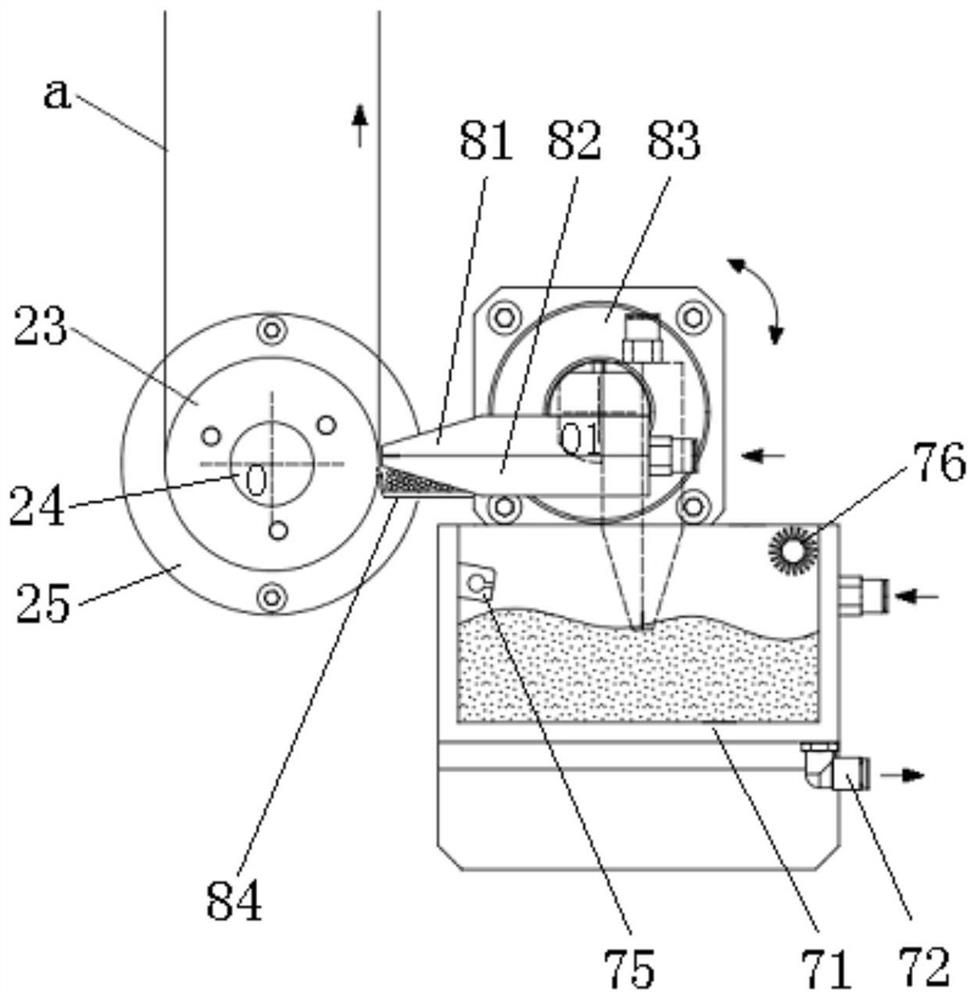

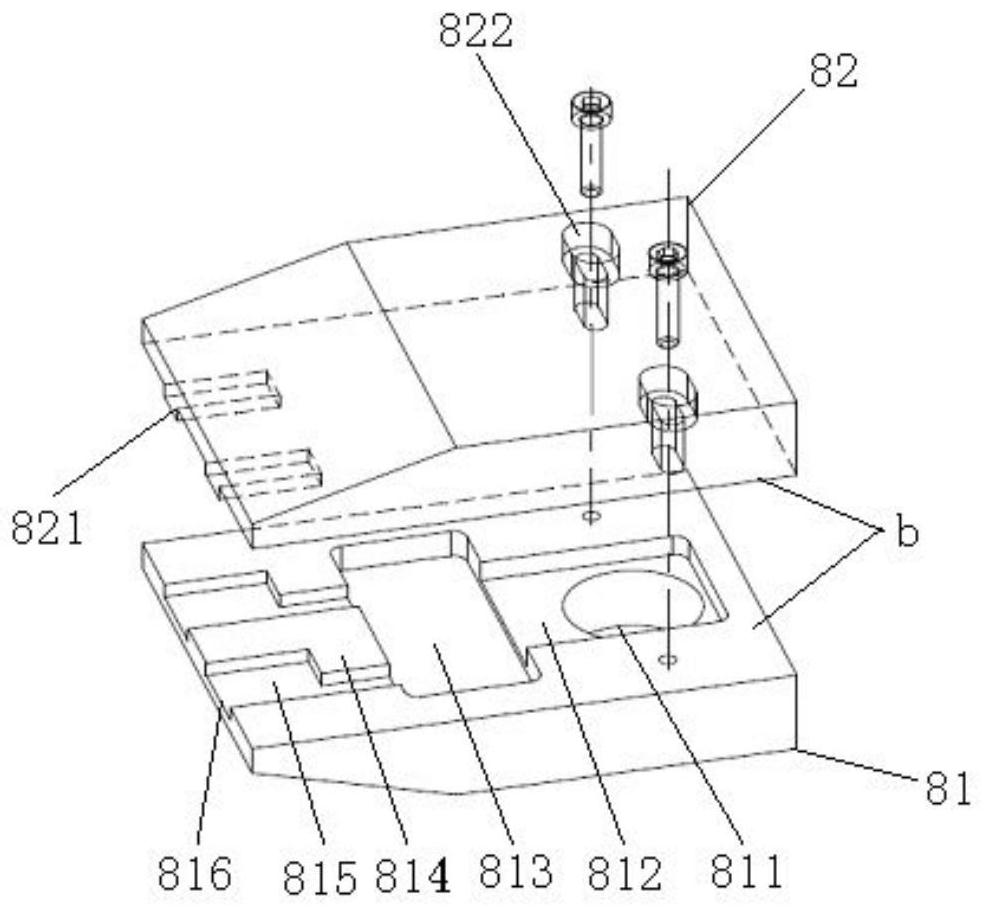

[0055] The gluing mechanism 8 is located between the glue supply mechanism 5 and the wrapping paper supply mechanism 2, and is used for gluing the centerline of the cigarette filter stick wrapping paper;

[0056] The cleaning mechanism 7 is located below the gluing mechanism 8 and is used to clean and moisturize the residual glue of the gluing mechanism 8 to prevent clogging;

[0057] The heating guide mechanism 4 is located on the upwardly extending path of the wrapping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com