Control method of double-liquid dispensing automatic calibration system

A technology of automatic calibration and control method, which can be applied to devices and coatings that apply liquid to the surface. It can solve the problems of inability to perform glue output and monitoring, and achieve the effect of meeting calibration requirements and ensuring consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

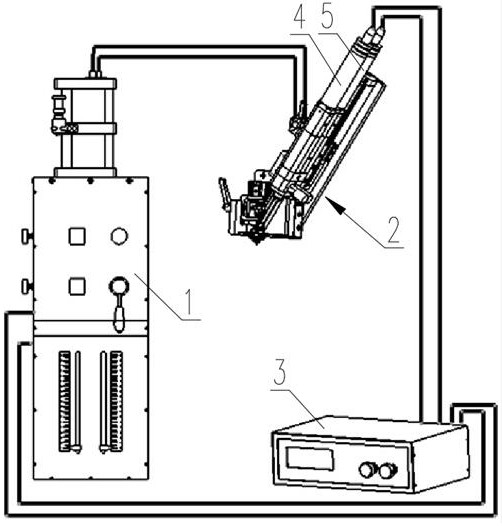

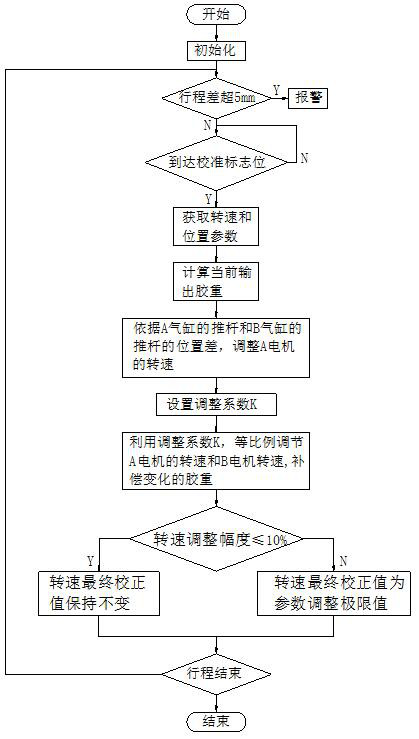

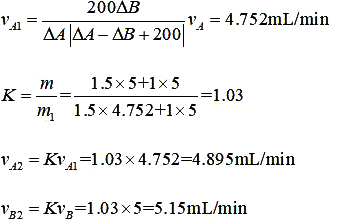

[0030] Such as figure 1 and 2 As shown, a control method of a two-liquid dispensing automatic calibration system, the two-liquid dispensing automatic calibration system includes a glue supply device 1 and a two-component dispensing assembly 2, and the glue supply device 1 has a rubber cartridge A The A cylinder for pushing out the glue inside and the B cylinder for pushing out the glue in the B glue cartridge. The glue port is connected, and the glue inlet of the B rubber cylinder and the B screw pump 5 is connected. The control method includes the following steps:

[0031] Controller 3 can be initialized before step S1;

[0032] S1. Detect stroke difference. The difference between the current position of the push rod of cylinder A and the current position of the push rod of cylinder B is the stroke difference. If the stroke difference is greater than 5mm, the double-liquid dispensing automatic calibration system will stop and give an alarm; if the stroke difference ≤5mm, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com