Machining forming machine and machining method for metal connecting tube of automobile air conditioner

A technology of metal connection and processing and forming, applied in metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc., can solve problems such as inability to realize batch processing, complex structure of manipulators, and affecting grinding efficiency, and achieve structural Simple, improve grinding efficiency, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific illustration. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict.

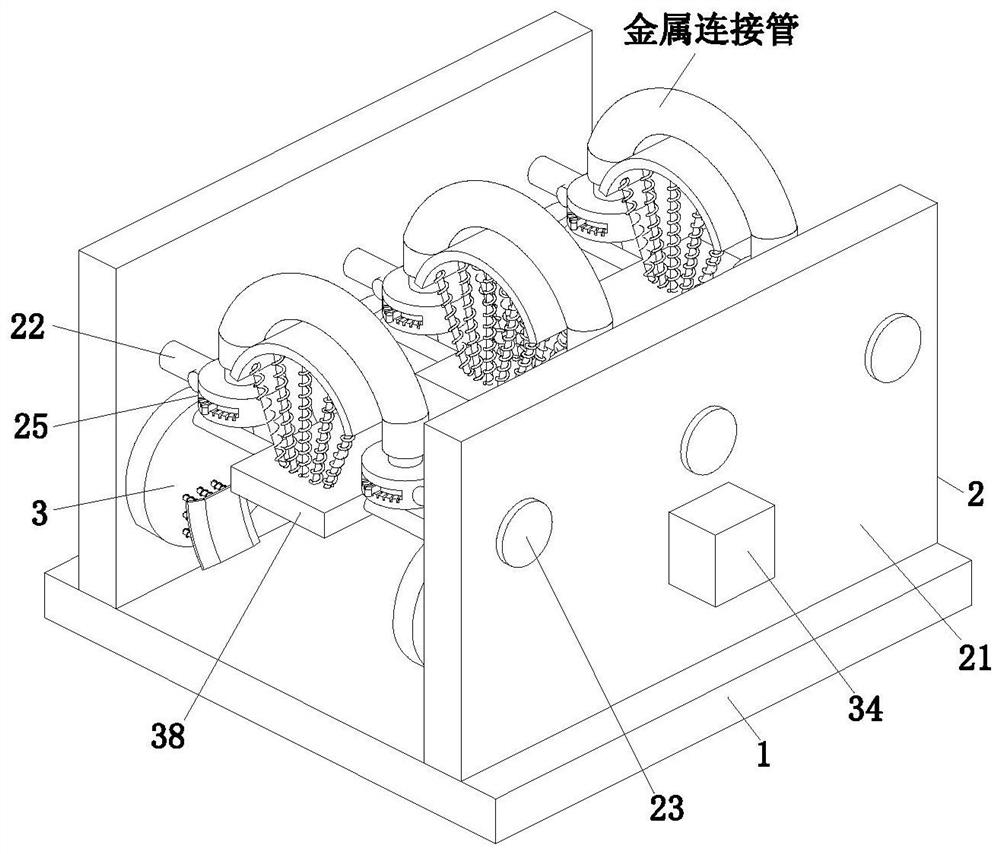

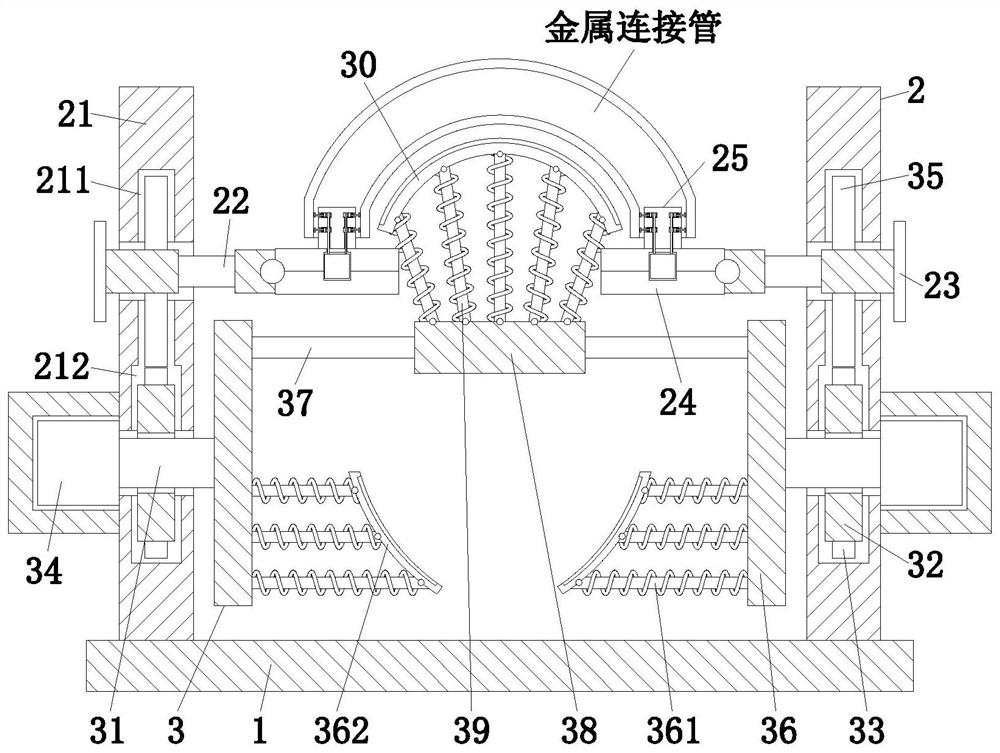

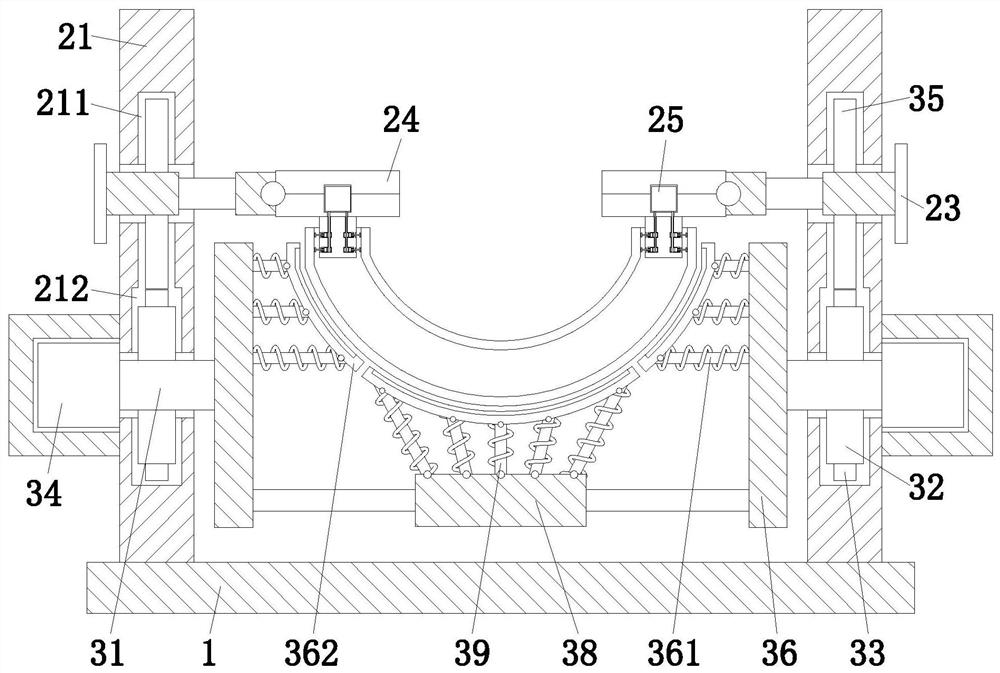

[0037] like Figure 1 to 9 As shown, a car air conditioning metal connection is machined, including the base 1, the support unit 2, and the grinding unit 3, and the upper end of the base 1 is provided with a support unit 2 inside the support unit 2, wherein the body 3 is mounted.

[0038] The support unit 2 includes a support plate 21, a stretch column 22, a restricted plate 23, a carrier plate 24, and a fixing assembly 25, wherein the support plate 21 is configured to be mounted on the upper end of the base 1, and the upper side of the support plate 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com