Dry-method paving system of wall and floor tiles

A technology for walls, floors and ceramic tiles, applied in the direction of construction and building structure, can solve the problems of low construction efficiency, high technical requirements of workers, long construction period, etc., and achieve the effect of simple construction, avoiding process methods, and firm paving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

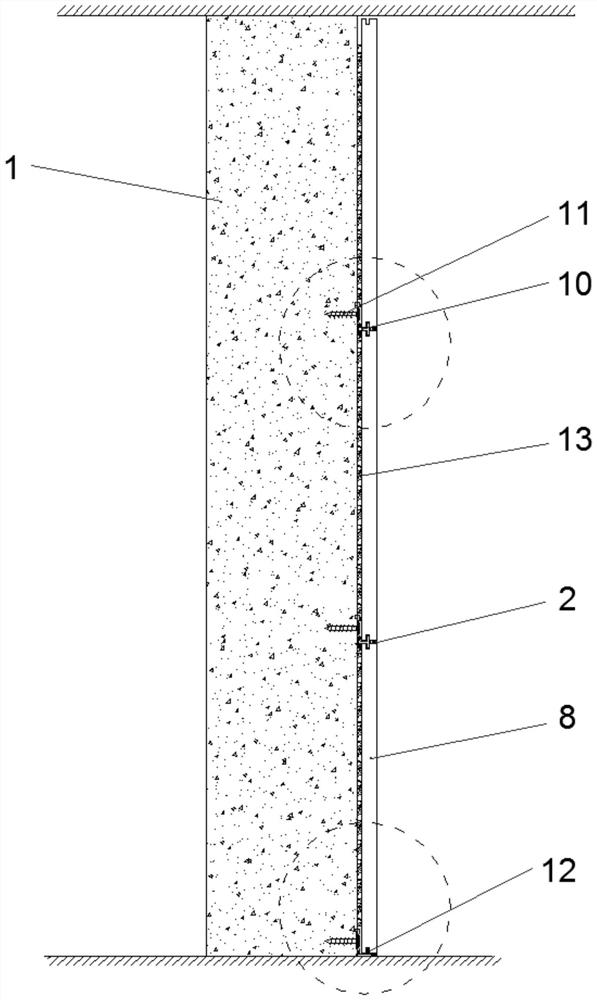

[0056] A dry method paving system for wall and floor tiles, including a number of dry method paving tiles arranged on the wall leveling base and the ground leveling base, the side of the dry method paving tiles is provided with a connecting card slot, and the adjacent dry method paving The connection between the installed tiles is provided with a first tile connector, and the first tile connector is installed on the wall leveling base and the ground leveling base through fixing screws. Adapted first connection protrusion, the first connection protrusion is clamped in the connection card slot, the joint between the dry paving tile and the ground leveling base is provided with a second tile connector, and the dry paving tile and the ground leveling base are provided with a second tile connector. The joint of the wall leveling base is provided with a second ceramic tile connector, and the second ceramic tile connector is installed on the wall leveling base and the ground leveling ...

Embodiment 2

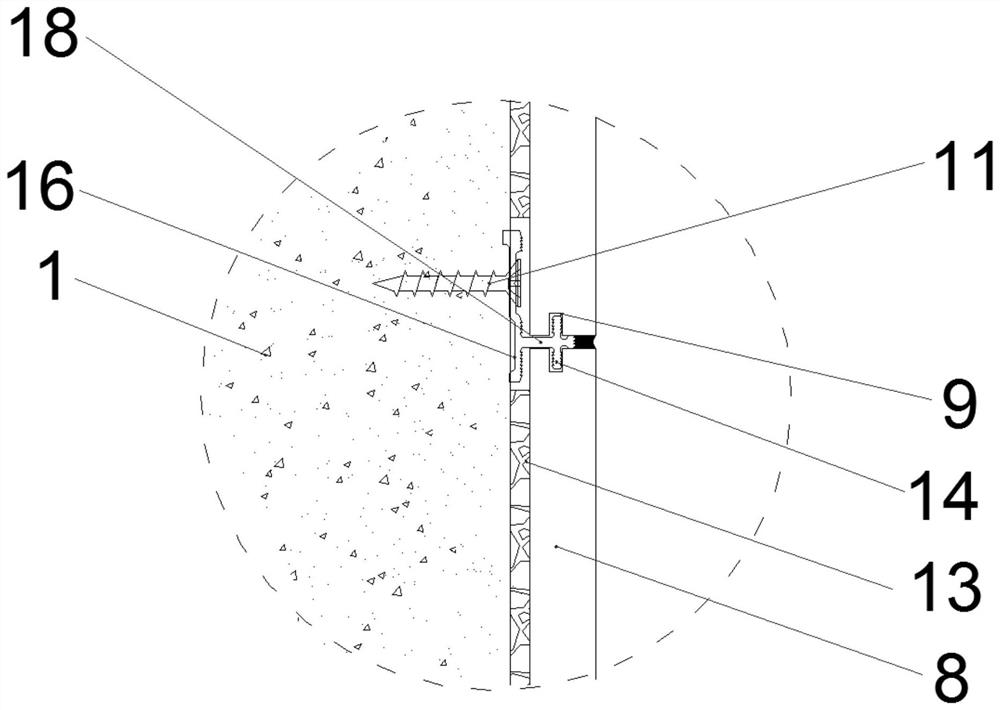

[0059] On the basis of Embodiment 1, the first tile connector includes a base for installing fixing screws, the base is provided with screw positioning lines, and the first connection protrusion includes a support foot vertically connected to the base, supporting A double-headed support arm is horizontally connected to the foot, and the double-headed support arm is clamped in the connection slot, and a split strip is vertically connected to the support foot. The surface of the base close to the side of the dry-laid tile is provided with a number of inverted Teeth, the double-headed support arm is provided with a number of inverted teeth, and the top of the slit strip is provided with a sawtooth groove.

[0060] Through this setting, the inverted teeth are set at the joint between the base and the tiles, which can increase the bonding strength of the glue when sizing. A jagged groove is set at the end of the split strip, which can increase the adhesion of the subsequent beautif...

Embodiment 3

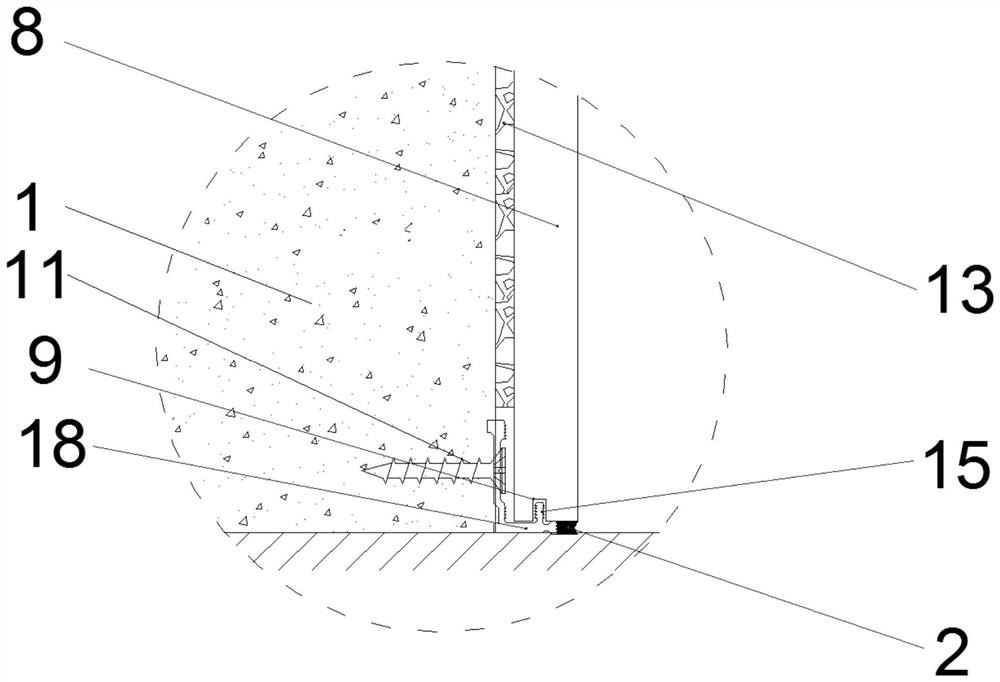

[0062] On the basis of the above embodiment, the second tile connector includes a base for installing fixing screws, and the base is provided with screw positioning lines, and the second connection protrusion includes supporting feet vertically connected to the base, supporting A single-headed support arm is horizontally connected to the foot, and the single-headed support arm is clamped in the connection card slot, and a split strip is vertically connected to the support foot. A number of downturns are arranged on the surface of the base near the side of the dry-laid tile. Teeth, the single-head support arm is provided with a number of inverted teeth, and the top of the slit strip is provided with a sawtooth groove.

[0063] Through this setting, the inverted teeth are set at the joint between the base and the tiles, which can increase the bonding strength of the glue when sizing. A jagged groove is set at the end of the split strip, which can increase the adhesion of the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com