Mixed working medium low-temperature refrigeration cycle system adopting ejector and control method thereof

A technology of circulation system and mixed working fluid, applied in the field of refrigeration and low temperature, can solve the problem of high discharge pressure of the compressor, and achieve the effect of reducing the starting discharge pressure, the system structure is simple and the structure is compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

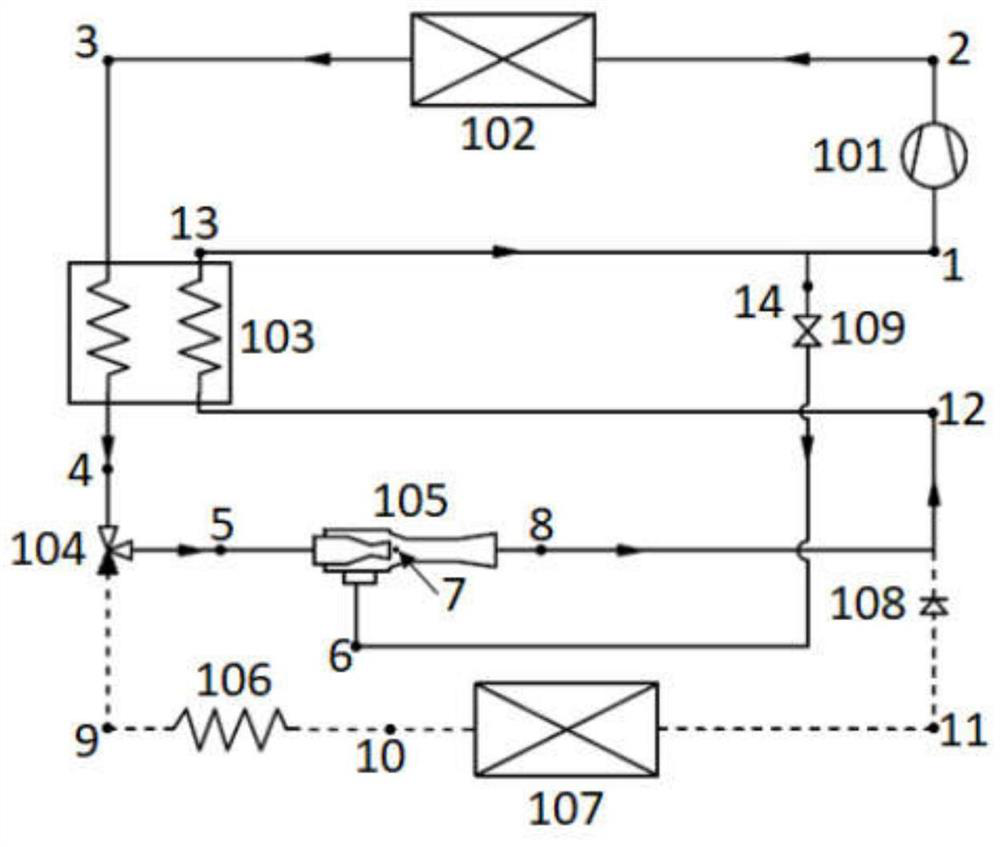

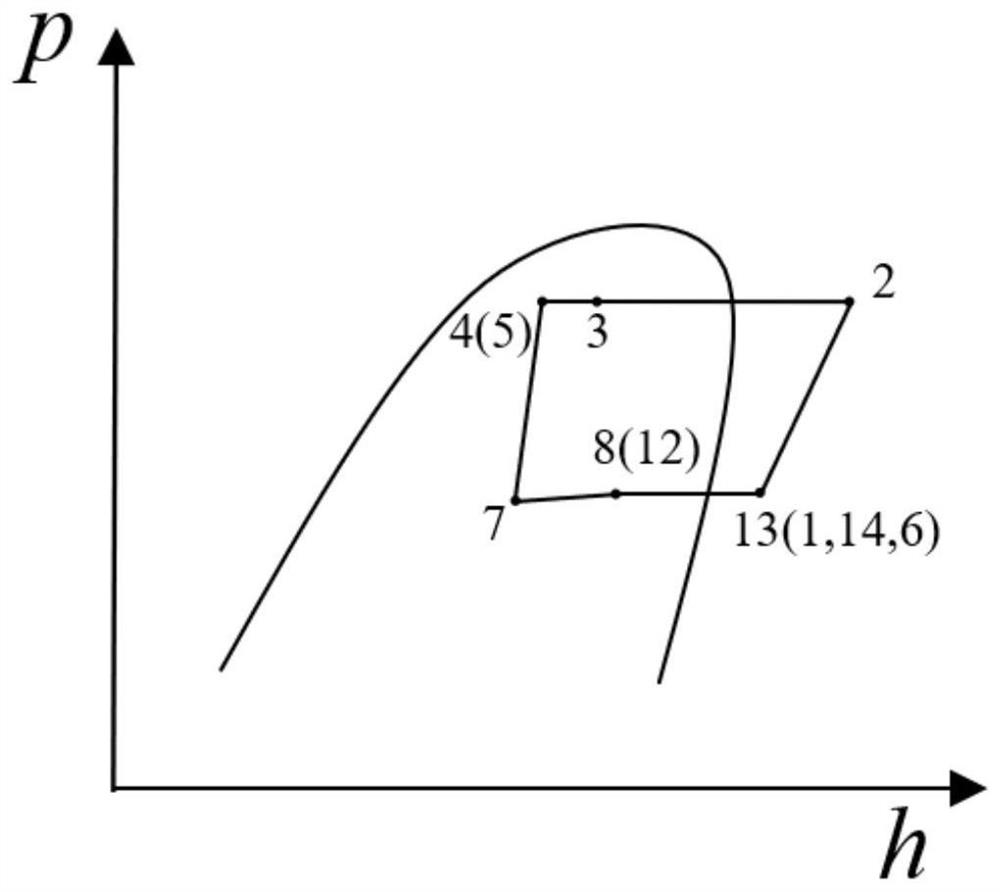

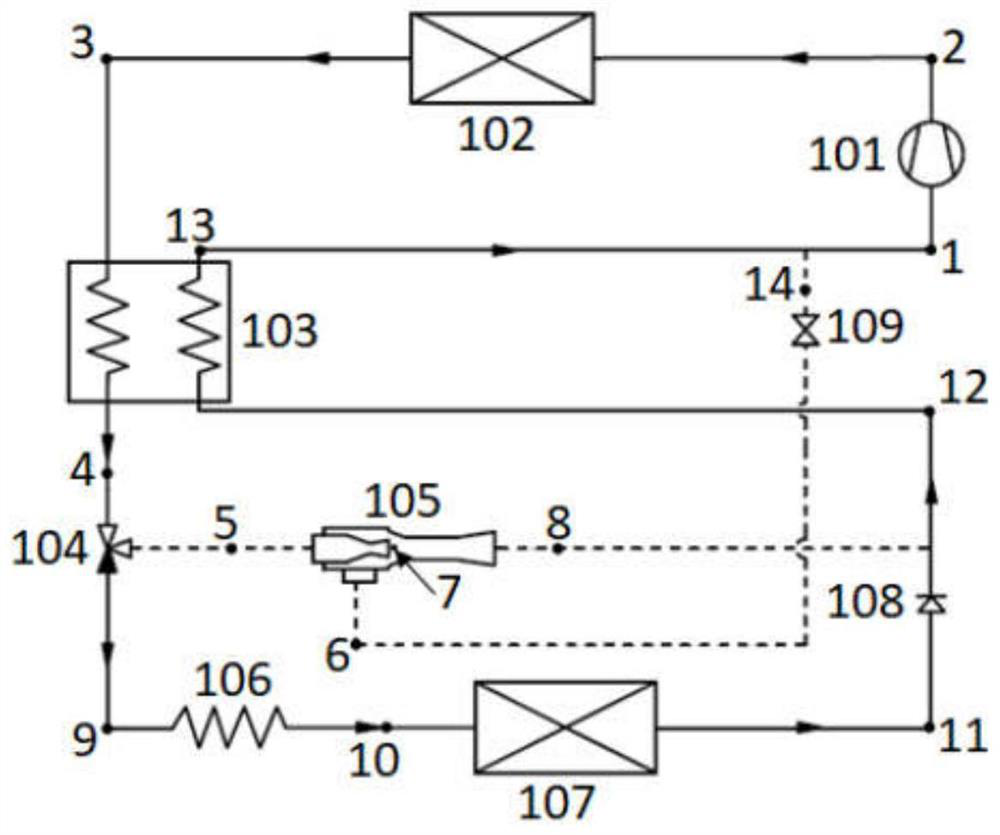

[0024] The refrigeration system has two working modes, including startup mode and cooling mode, and the specific working methods are as follows:

[0025] (1) Start mode

[0026] Such as Figure 1-a As shown, it is a mixed working medium low-temperature refrigeration cycle system using an ejector. In the start-up mode, it includes a compressor 101, a condenser 102, a regenerator 103, a two-position three-way solenoid valve 104, an ejector 105 and an electromagnetic Valve 109; the high-pressure gaseous mixed working medium at the outlet of the compressor 101 is cooled into a gas-liquid two-phase mixed working medium in the condenser 102, and then enters the heat flow side of the regenerator 103 to be further cooled, but at the start-up stage, The outlet temperature of the evaporator 107 is high, and the heat recovery effect is poor. The refrigerant that is further cooled by the heat recovery device 103 still cannot be completely condensed, so the gas-liquid two-phase refrigerant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com