Bergamot pear pulp crispness detection method based on force-sound synchronous acquisition

A technology of synchronous acquisition and detection methods, which is applied in the direction of measuring devices, processing detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., and can solve problems such as complex test devices, difficult synchronization, and high sensor prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings.

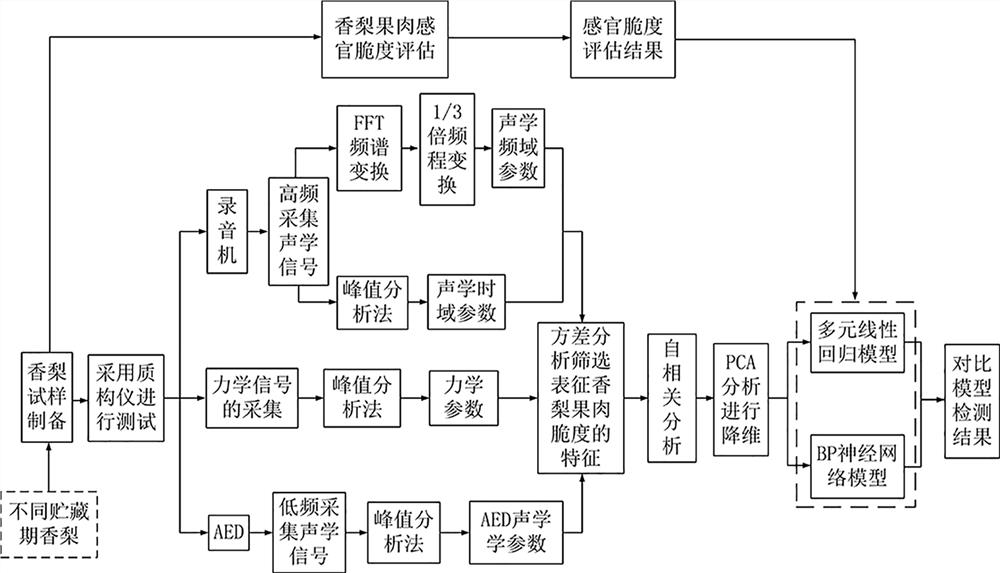

[0087] refer to figure 1 As shown, the steps of the method for detecting the crispness of pear pulp based on the synchronous collection of force sound of the present invention are as follows:

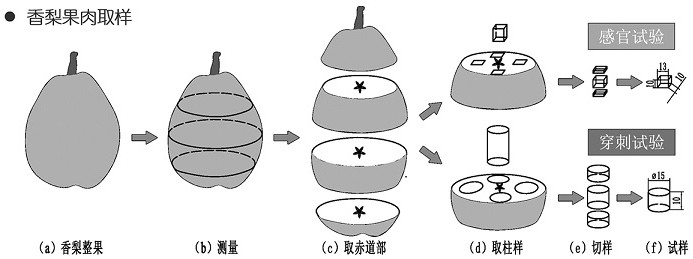

[0088] (1) Acquisition and analysis of mechanical and acoustic signals when the pear pulp is broken

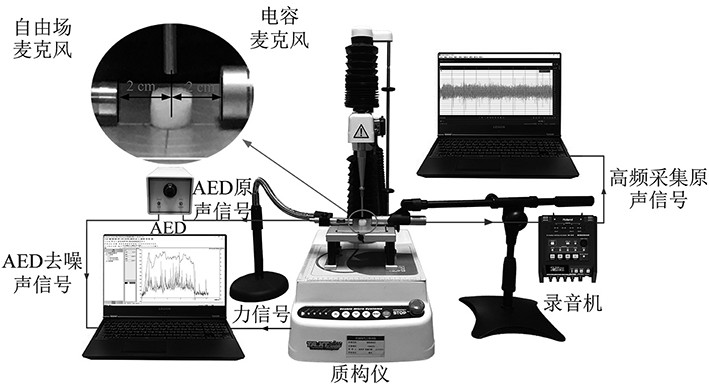

[0089] The texture analyzer puncture mode was used to carry out the puncture test of the fragrant pear pulp, the mechanical signal of the fragrant pear sample was collected by the pressure sensor and the computer, and the acoustic signal of the fragrant pear was collected by the AED and the recorder respectively. Denoise the acoustic signal collected by the tape recorder; use the peak method to extract mechanical features from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com