ERP enterprise self-supply production and marketing integrated allocation system

An enterprise, production and sales technology, applied in the field of production and sales integration deployment system, can solve problems such as domestic sales, EPR application, etc., to achieve the effect of increasing employee income, achieving balance between production and sales, and promoting word-of-mouth publicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

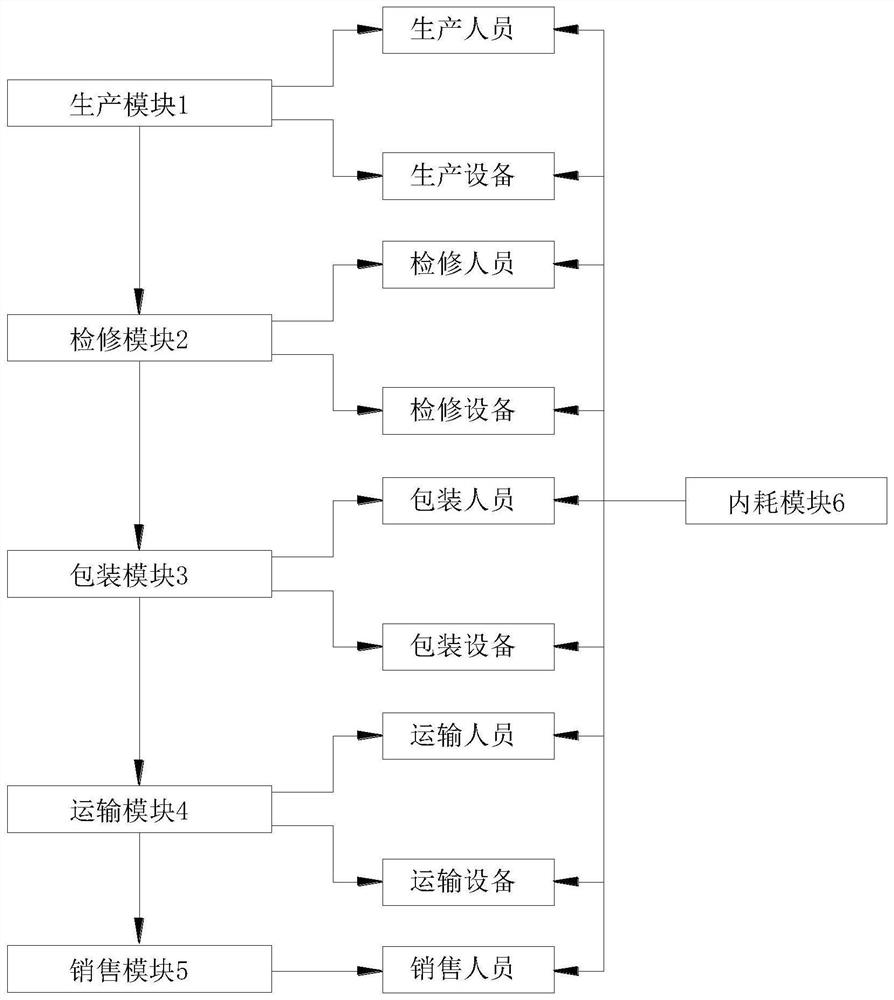

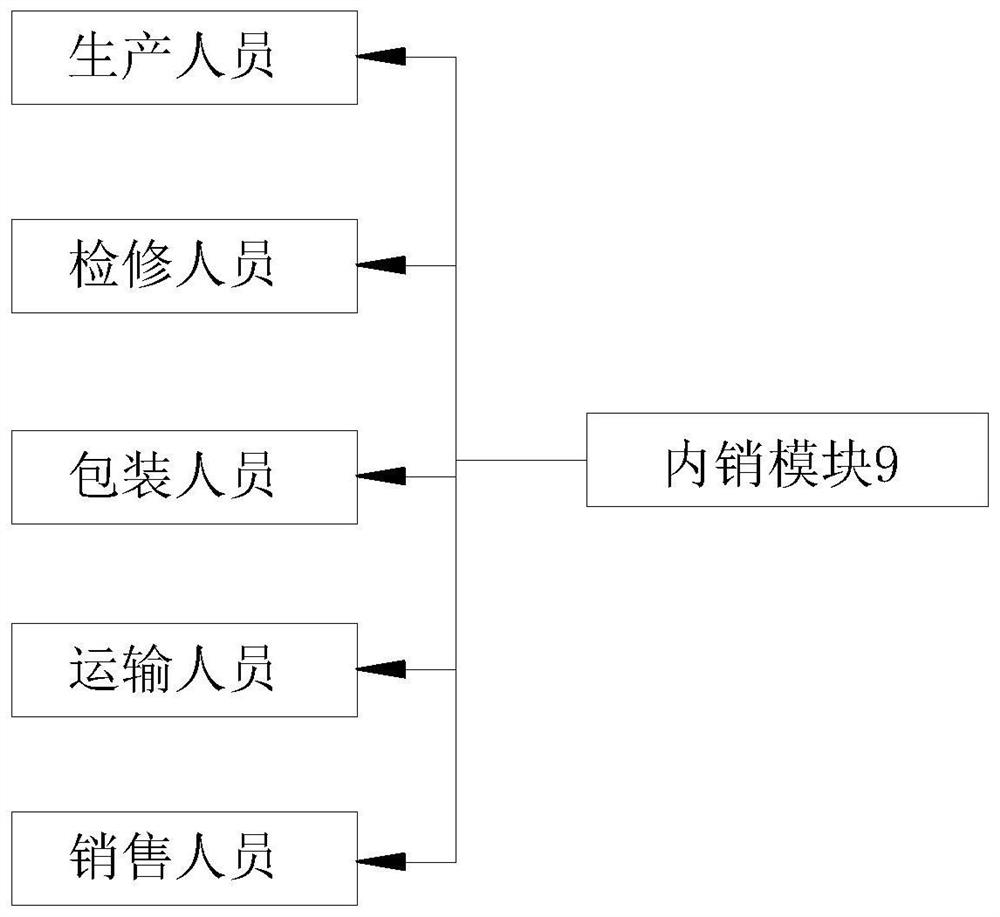

[0032] refer to Figure 1 to Figure 5, an ERP enterprise self-supplied production-sales integration deployment system, including production module 1, maintenance module 2, packaging module 3, transportation module 4 and sales module 5, production module 1 and maintenance module 2 are connected to each other, production module 1 outputs After the products enter the maintenance module 2, they are divided into qualified products 13 and unqualified products 12. The unqualified products 12 stay in the maintenance module 2 for maintenance. The maintenance module 2 is connected with the packaging module 3 and the internal friction module 6. The qualified products 13 enter the internal friction module 6 and packaging module 3, and the packaging module 3 outputs packaging products 11, the packaging module 3 is connected to the transportation module 4, the transportation module 4 is connected to the sales module 5, and the packaging products 11 enter the sales module 5 through the transp...

Embodiment 2

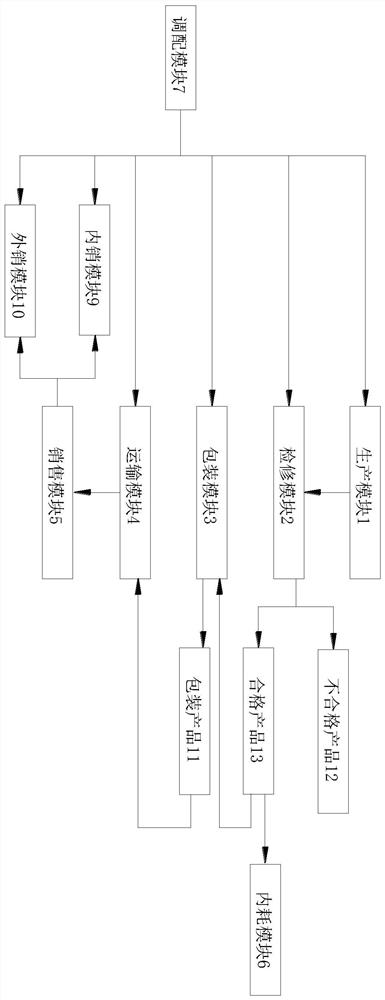

[0050] refer to Figure 6 to Figure 7 , the difference between the present embodiment and the first embodiment is only that the present embodiment adds a secondary sales module 8, which is used to process unqualified products 12 and returned products, thereby reducing the scrap rate and reducing costs. The export module 10 is connected to the maintenance module 2, and the maintenance module 2 is connected to the secondary sales module 8. In the export module 10, the products returned after export failure enter the maintenance module 2, and the three qualified products 23 are obtained after passing the maintenance, and the output of the production module 1 is unqualified. The product 12 enters the inspection module 2, and the second qualified product 22 is obtained after passing the inspection.

[0051] The secondary sales module 8 is connected with the allocation module 7, and the allocation module 7 coordinates the secondary qualified products 22 and the tertiary qualified pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com