Relay with high fixing performance

A relay and performance technology, applied in the field of relays with strong fixed performance, can solve the problems of inconvenient installation and fixation of thermal relays, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

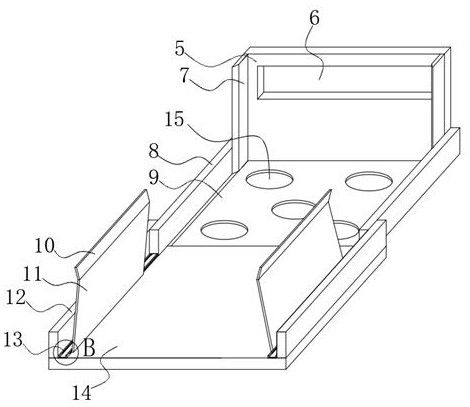

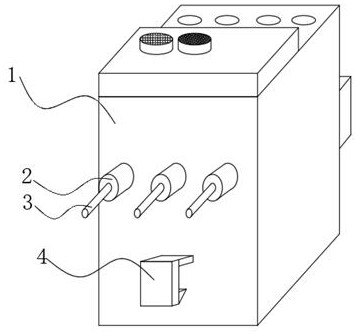

[0031] A relay with strong fixed performance, such as Figure 1-7As shown, it includes a first base plate 9, a relay body 1, and a second base plate 14. The rear end of the top of the first base plate 9 is fixed with a back plate 5 by bolts, and the top of the two ends of the back plate 5 has mounting holes 6. 5 Both sides of the front end are fixed with side plates 7 by screws, the bottoms of both sides of the back plate 5 are fixed with first baffles 8 by bolts, and one side between the two first baffles 8 is connected to two A side plate 7, and there is a gap between the two first baffle plates 8 and the first bottom plate 9, the middle and both sides of the bottom of the two first baffle plates 8 are provided with rectangular grooves, and the two sides of the rectangular grooves in the middle There are rectangular through-holes on the sides, and a number of rollers 17 are inserted into the two rectangular through-holes, and a turntable 20 is fixedly installed on one end of...

Embodiment 2

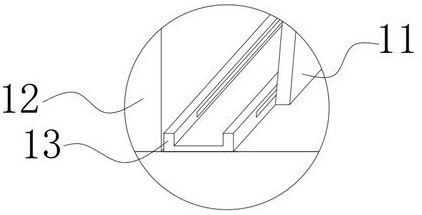

[0039] A relay with strong fixed performance, such as Figure 8 As shown, in order to solve the problem of insufficient clamping force of the plastic splint 11; this embodiment makes the following improvements on the basis of Embodiment 1: the middle part of one side between the two second baffles 12 is fixed with bolts. Cylindrical box 24, and two cylindrical boxes 24 have circular openings on the side away from the second baffle plate 12, and the sides of the two cylindrical boxes 24 circular openings away from the swash plate 10 are all fixed First gaskets 25 are installed, and springs 26 are fixedly installed on the sides of the two first gaskets 25 away from the second baffle plate 12 .

[0040] In the present invention, the ends of the two springs 26 away from the first gasket 25 are fixedly installed with the second gasket 27 , and the sides of the two second gaskets 27 away from the second baffle 12 are connected to the plastic splint 11 .

[0041] When the present em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com