Cable connector

A technology of cable connectors and limit sleeves, which is applied in the direction of connection, multi-core cable end parts, and parts of connection devices, etc., which can solve the problem of inability to realize quick assembly and quick disassembly, increase connector assembly time, increase cost, etc. problems, to achieve the effect of ensuring firmness and stability, ensuring firmness, and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

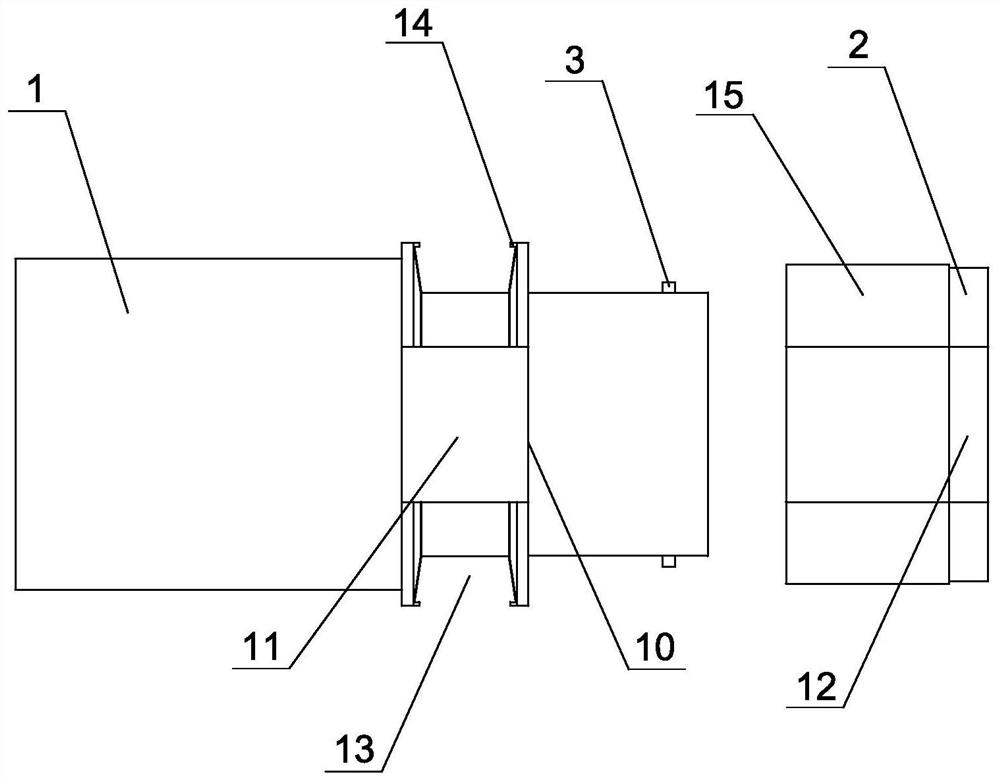

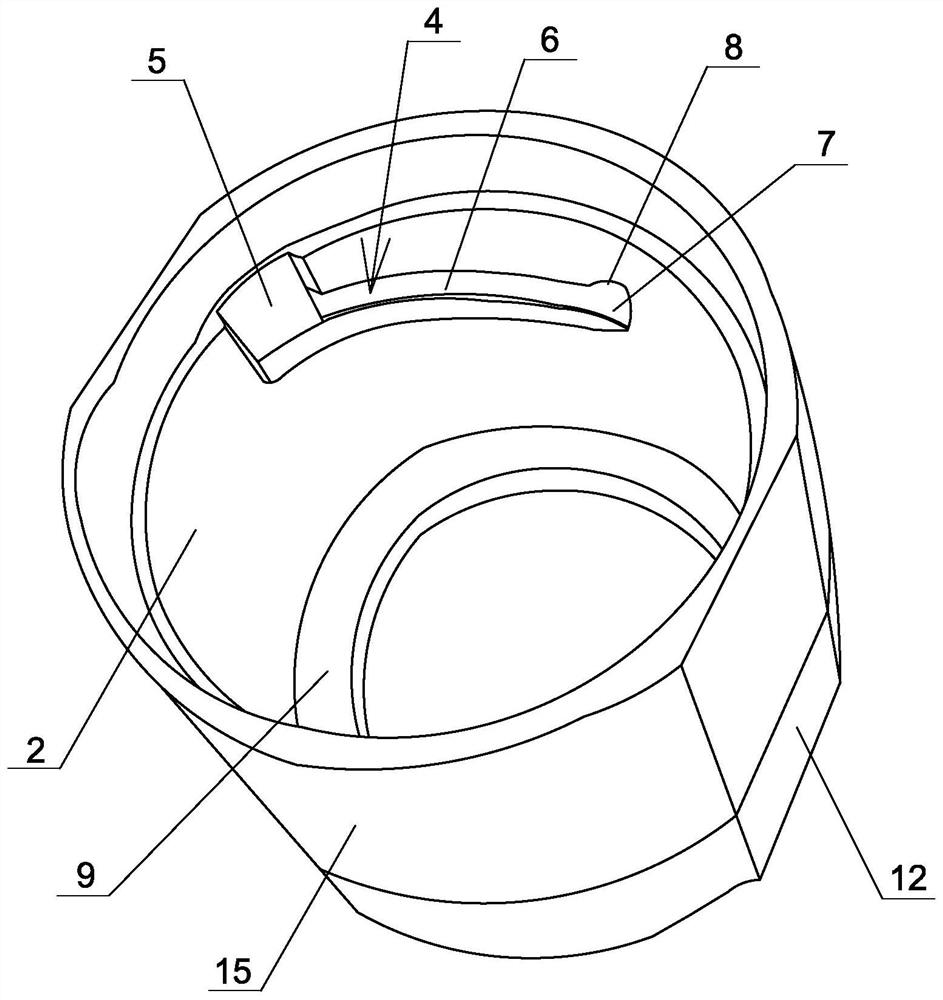

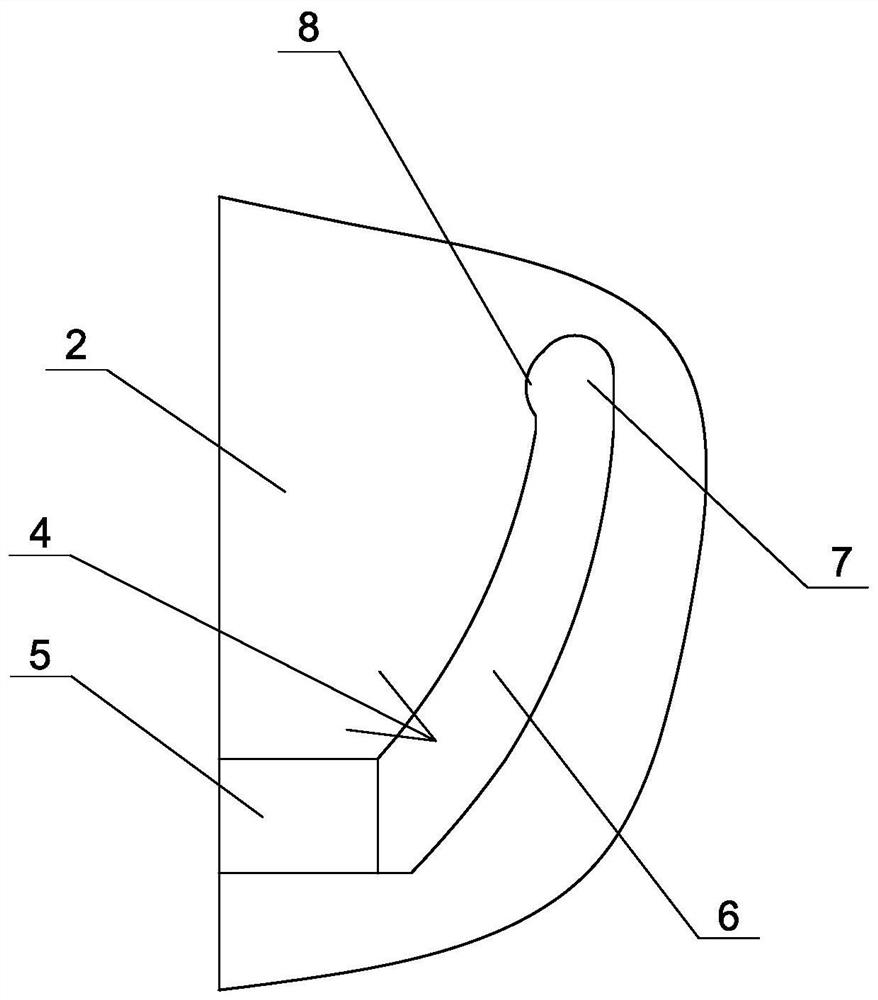

[0022] Embodiment one: see Figure 1~3 As shown, a cable connector includes a body 1, the right end of the body is provided with a limit sleeve 2 for limiting the cable, the left end of the body is provided with a plug-in terminal, and the outer edge surface of the right end of the body There are two groups of limiting protrusions 3 arranged symmetrically on the top, and two groups of limiting grooves 4 are symmetrically arranged on the inner wall of the limiting sleeve. The front ends of the limiting grooves communicate with the left side of the limiting sleeve. The limit sleeve is inserted on the right end of the body, each set of limit protrusions is inserted into a set of limit slots, and the limit sleeve is rotated to lock the limit protrusions Located at the right end of the limiting groove, the limiting protrusion and the limiting groove lock and connect the body and the limiting sleeve.

[0023] In this embodiment, a screw sleeve is provided on the left side of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com