Hardware protection circuit for photovoltaic inverter

A photovoltaic inverter and hardware protection technology, applied in safety/protection circuits, emergency protection circuit devices, photovoltaic power generation, etc., can solve the problem of large differences in the action time of protection points, large influence of hardware circuit temperature, and slow protection action time, etc. problem, to achieve good economic use value, fast fault response, and slow action time to solve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

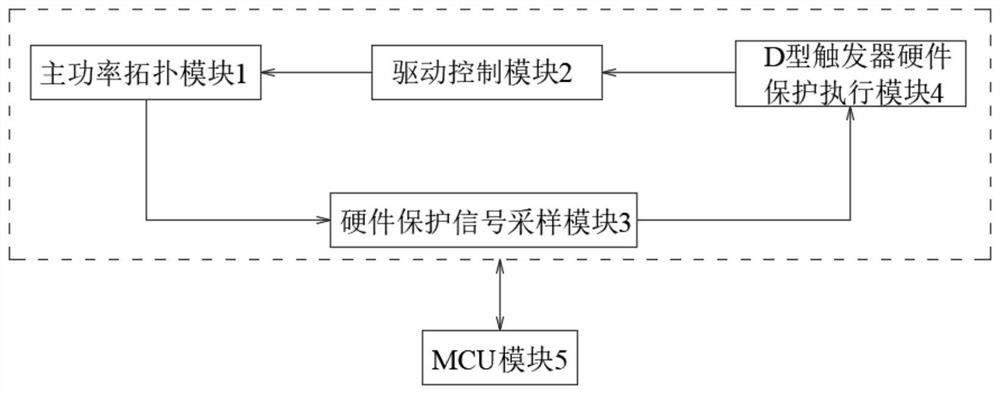

[0027] like Figure 1 to Figure 7 As shown, a hardware protection circuit for a photovoltaic inverter of the present invention includes:

[0028] The main power topology module 1 is connected with the hardware protection signal sampling module 3, and is used for fault signal detection and sends the signal to the hardware protection signal sampling module 3;

[0029] The drive control module 2 is connected to the main power topology module 1, and is used to provide a driving signal for the main power topology module 1;

[0030] The hardware protection signal sampling module 3 is connected with the D-type flip-flop hardware protection execution module 4, and is used to detect the fault signal received from the main power topology module 1, and send the generated trigger hardware fault signal to the D-type flip-flop hardware Protect execution module 4;

[0031] The D-type flip-flop hardware protection execution module 4 is connected to the drive control module 2, and is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com