Leather peening device for leather shoe processing

A leather and hammer leveling technology, applied in the field of leather hammer leveling devices for leather shoe processing, can solve the problems of easy wear of the crankshaft, pollute the environment, increase energy consumption, etc., and achieve the effects of saving energy, preventing pollution and improving the production efficiency of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

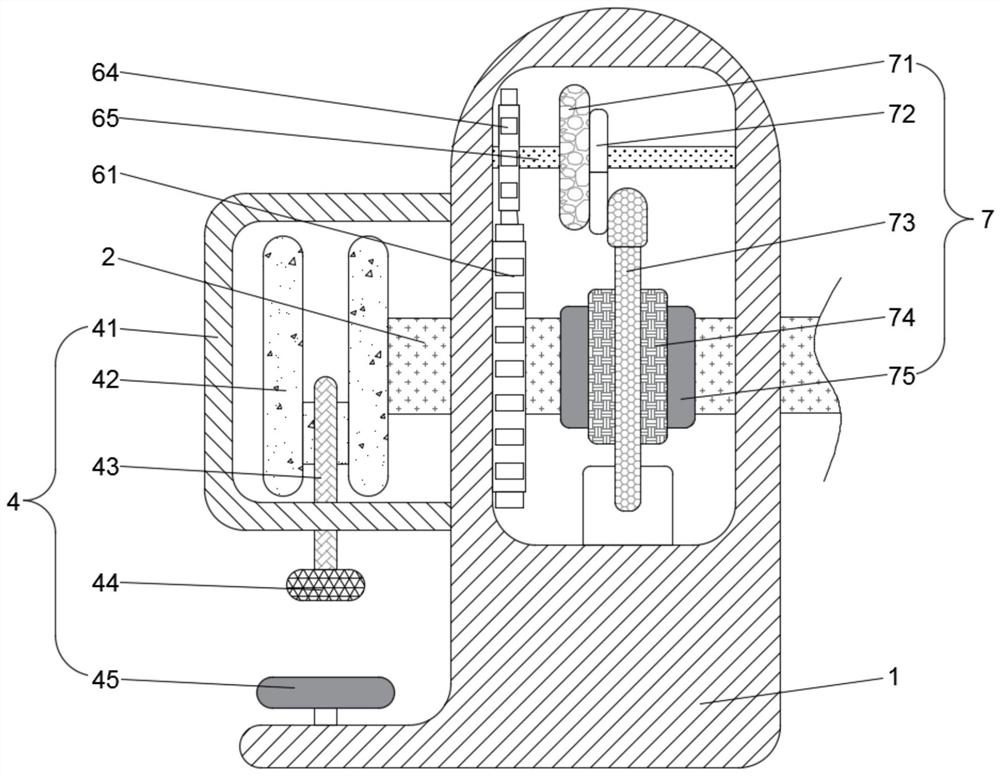

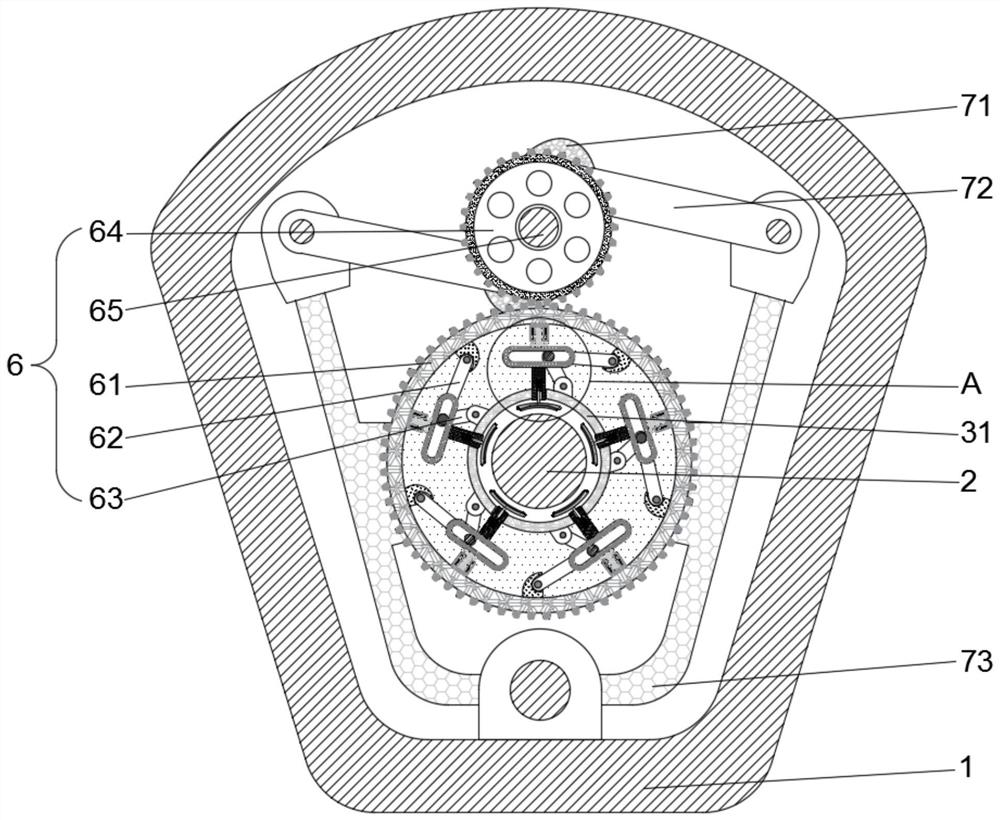

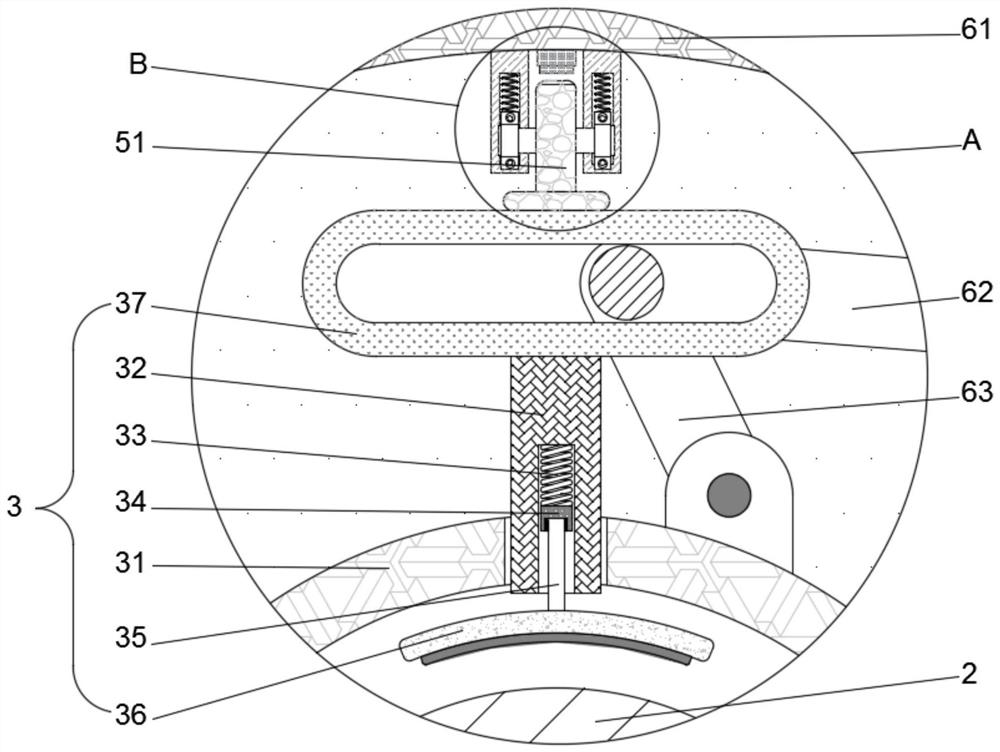

[0024] see figure 2 , a leather hammer leveling device for leather shoe processing, comprising a box body 1, a rotating shaft 2 is movably connected to the middle part of the box body 1, and a detection mechanism 3 is movably connected to the left side of the inside of the box body 1, and the detection mechanism 3 includes a guide ring 31, the guide ring 31 The middle part is movably connected with a moving block 32, and the middle part of the guide ring 31 is provided with a groove compatible with the moving block 32 for installing the moving block 32 to facilitate the movement of the moving block 32. The middle part of the moving block 32 is movably connected with a slide block through a compression spring 33 34, the middle part of the moving block 32 is provided with a hole suitable for the slider 34, which is used to install the slider 34 and facilitate the movement of the slider 34. The inner side of the slider 34 is fixedly connected with a push rod 35, and the inner end...

Embodiment 2

[0030] see Figure 1-4 , a leather hammer leveling device for leather shoe processing, comprising a box body 1, a rotating shaft 2 is movably connected to the middle part of the box body 1, and a detection mechanism 3 is movably connected to the left side of the inside of the box body 1, and the detection mechanism 3 includes a guide ring 31, the guide ring 31 The middle part is movably connected with a moving block 32, and the middle part of the guide ring 31 is provided with a groove compatible with the moving block 32 for installing the moving block 32 to facilitate the movement of the moving block 32. The middle part of the moving block 32 is movably connected with a slide block through a compression spring 33 34, the middle part of the moving block 32 is provided with a hole suitable for the slider 34, which is used to install the slider 34 and facilitate the movement of the slider 34. The inner side of the slider 34 is fixedly connected with a push rod 35, and the inner e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com