Centralized self-diagnosis vacuum desorption device and use method thereof

A self-diagnosing and centralized technology, applied in separation methods, preparation of test samples, complex mathematical operations, etc., can solve problems such as low work efficiency, energy waste, and time-consuming, and reduce equipment costs and system energy consumption Low, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

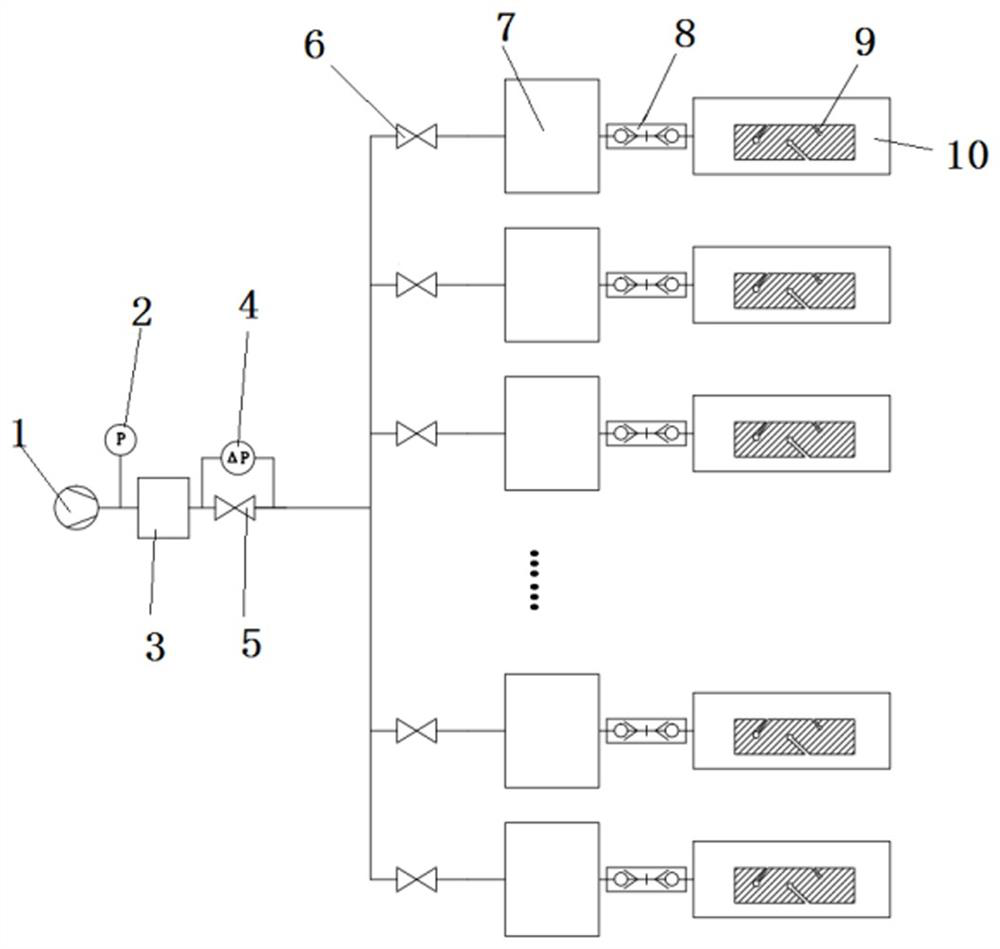

[0031] Such as figure 1 As shown, a centralized self-diagnostic vacuum desorption device includes: a vacuum pump 1, a vacuum sensor 2, a reference chamber 3, a main valve 5, a differential pressure sensor 4, a data acquisition and analysis system and several desorption units, and is characterized in that : Each desorption unit includes a sub-valve 6, a vacuum chamber 7 and a sample chamber 10 containing a sample to be desorbed, and the sample chamber 10 and the vacuum chamber 7 are connected by a quick-connect plug group with a one-way valve .

[0032] When the present invention is in use, open the main valve 5 and all sub-valves 6, start the vacuum pump 1 to evacuate until the reading of the vacuum sensor 2 is a specified value, determine that the vacuuming is completed, close the vacuum pump 1, the main valve 5 and all sub-valves 6, record each The timing of the closing operation of sub-valve 6 is t 10 , t 20 ,...,t n0 ;

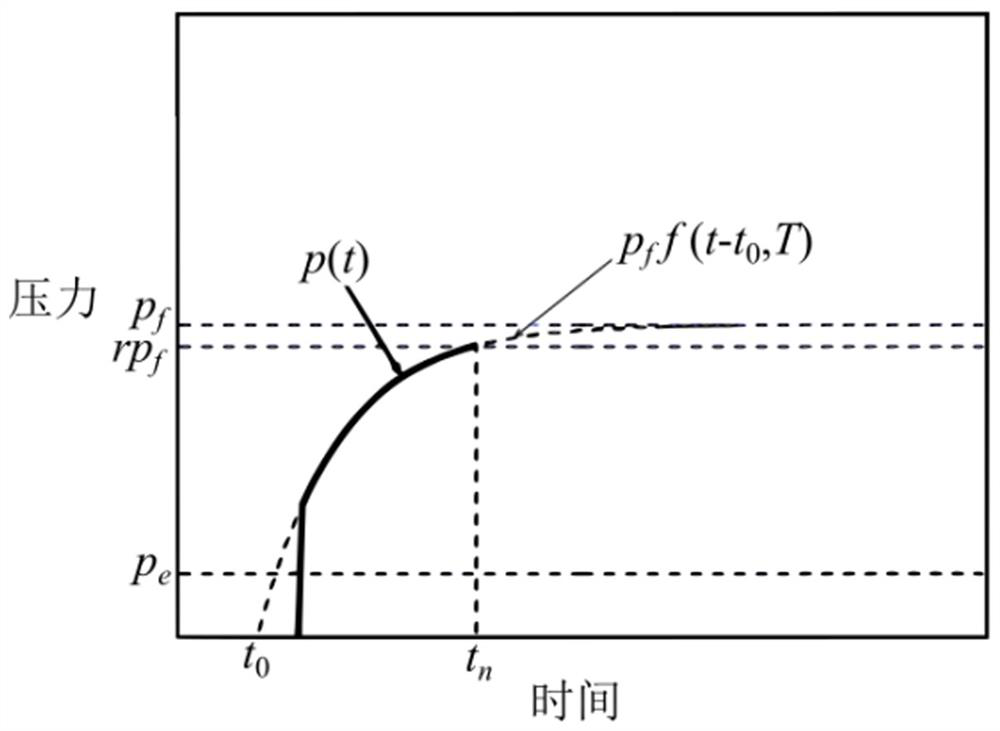

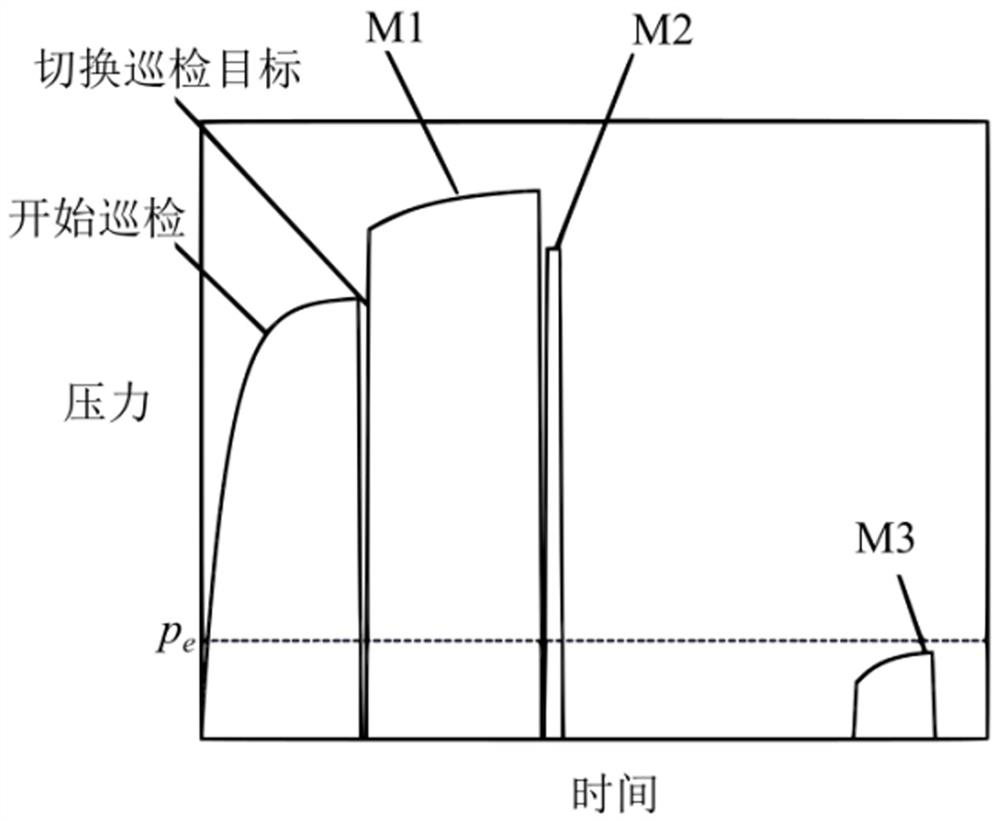

[0033] Start sequential inspections, taking the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com