Full-automatic intelligent ball valve production line

A fully automatic, production line technology, applied in the direction of cleaning methods, sorting, cleaning methods and utensils using gas flow, which can solve the problems of easy flow into the production line, inconvenient and timely separation of good and bad products, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

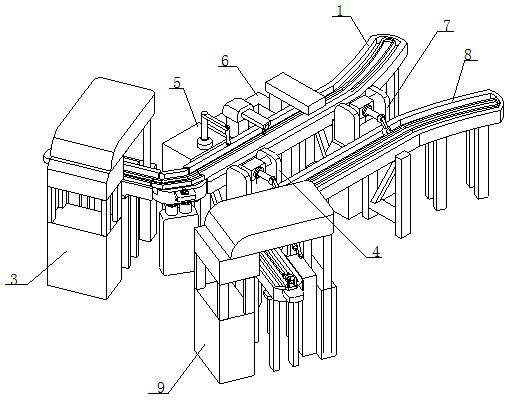

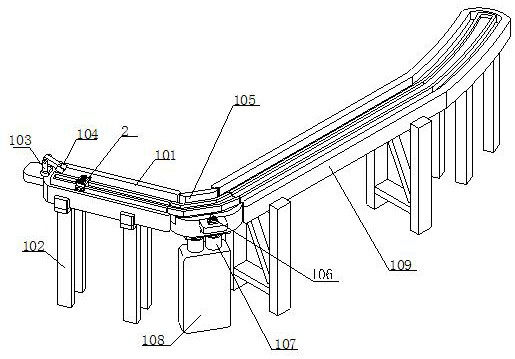

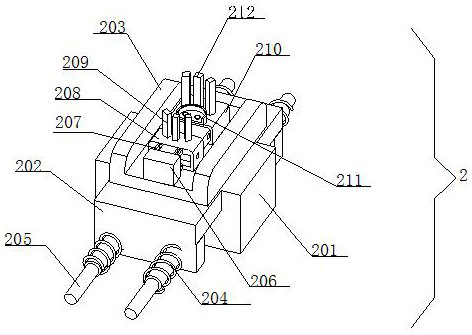

[0031] see Figure 1-3, the present invention provides a technical solution: a fully automatic intelligent ball valve production line, a valve seat feeding device 1, a delivery fixture 2 is installed on the inside of the valve seat feeding device 1, and a valve seat assembly device 3 is installed on one end of the valve seat feeding device 1. , the external movement of the valve seat feeding device 1 is equipped with a turning device-4, and the end of the valve seat feeding device 1 away from the turning device-4 is movably installed with a ball valve side screw cap installation device 5, and the ball valve side screw cap installation device 5 is assembled away from the valve seat One end of the device 3 is movably equipped with an airtightness detection device 6, and the end of the valve seat feeding device 1 away from the airtightness detection device 6 is movably installed with an overturning device 2 7; The bottom of the track one 101 is fixedly equipped with a bracket 102...

Embodiment 2

[0034] see Figure 4-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the interior of the valve seat assembly device 3 includes a fixed platform 301, and the top of the fixed platform 301 is movably installed with an installation crank arm 302, and the installation crank arm 302 is away from the fixed One end of table 301 is fixedly installed with mounting head 303, and one end of fixed table 301 is fixedly connected with supporting machine table 304; The inside of flipping device-4 includes turning machine table 401, and the top of turning machine table 401 is fixedly installed with side plate 402, and the side The inner wall of the plate 402 is movably equipped with a connecting shaft 403, and the outer wall of the connecting shaft 403 is fixedly equipped with a turning block 404, and the outer wall of the turning block 404 is movable, and the rotating arm 405 is movable, and the end of the turning arm 405 far away from the turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com