Automatic pigging ball launcher and automatic pigging method

A technology of pigging ball and launcher, applied in the direction of cleaning methods and utensils, chemical instruments and methods, pipes/pipe joints/pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

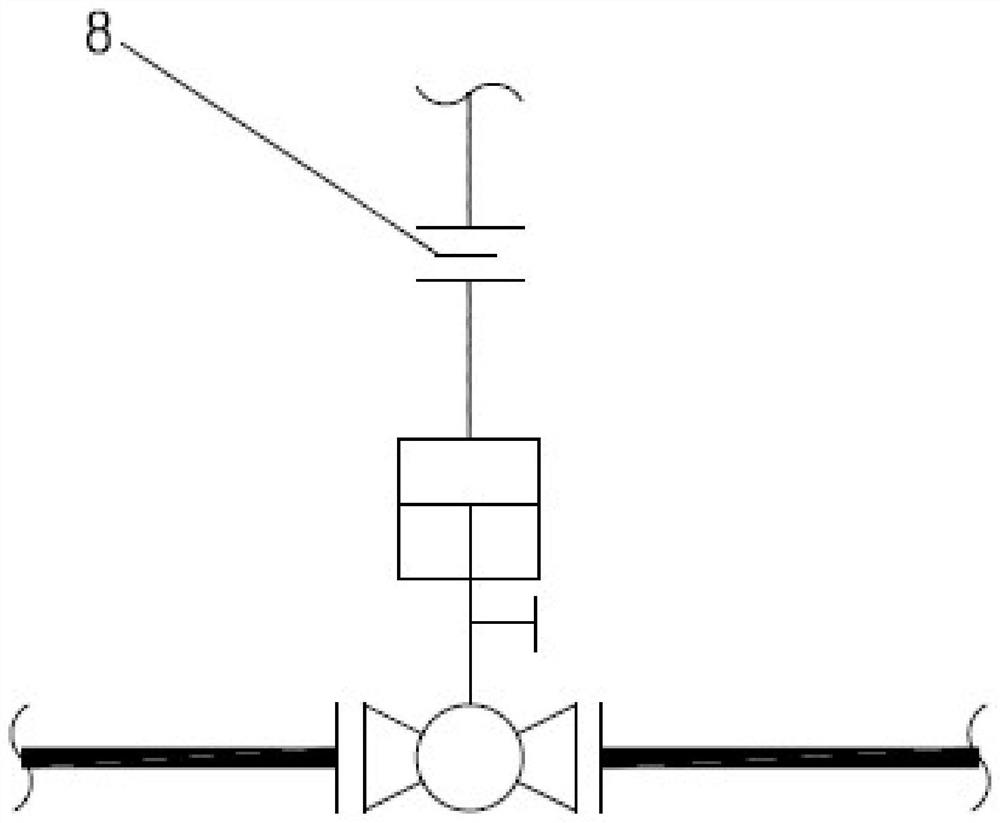

[0039] In order to better understand the purpose, structure and function of the present invention, an automatic pigging ball launcher and an automatic pigging method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

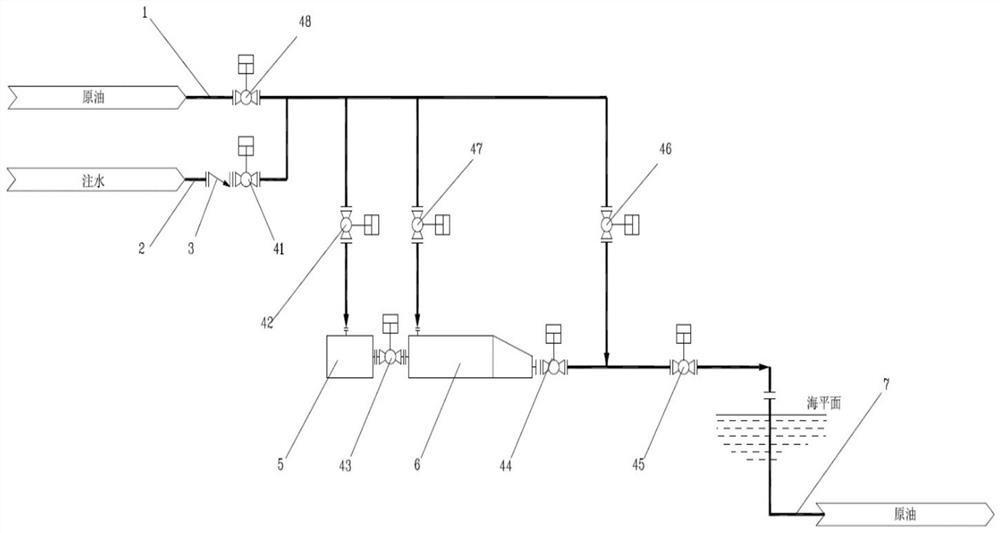

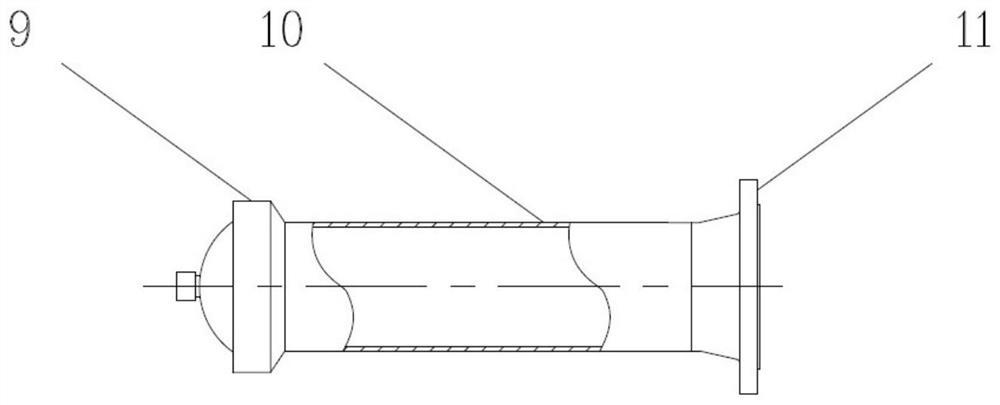

[0040] Such as Figure 1-Figure 4 As shown, the automatic pigging ball launcher of the present invention includes: two parallel transmission pipelines, wherein one transmission pipeline is: crude oil transmission pipeline 1, the eighth control valve 48 installed on crude oil transmission pipeline 1; The second delivery pipeline of the delivery pipeline; the second delivery pipeline is: the water injection delivery pipeline 2, the check valve 3 and the first control valve 41 sequentially installed on the water injection delivery pipeline 2;

[0041] The output ends of the above-mentioned two-way delivery pipelines are also connected with three-way, four-way, and five-way delivery pipelines, wherein, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap