Three-dimensional negative Poisson's ratio structure suitable for 3D printing

A negative Poisson's ratio, 3D printing technology, applied in the direction of processing and manufacturing, additive processing, etc., can solve the problems of negative Poisson's ratio structure cannot be formed, structure manufacturability limitations, etc., to achieve the effect of stable platform stress and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1, see Figure 7 a- Figure 7 c, the number of helical arms 1 of each helical unit 100 is three, the planar helical structure takes the inner end 11 of the helical arm 1 as the center of rotation, and the helical arm 1 takes 120° as the step size circular array 3 times to obtain the helical unit 100 , the two adjacent spiral units 100 on the X-axis, Y-axis and Z-axis (up and down) are mirror images, and the upper and lower adjacent spiral units 100 are connected by three inclined rods 2, and the upper and lower ends of the inclined rods 2 are respectively connected to the spiral The outer ends 12 of the unit 100 are connected.

Embodiment 2

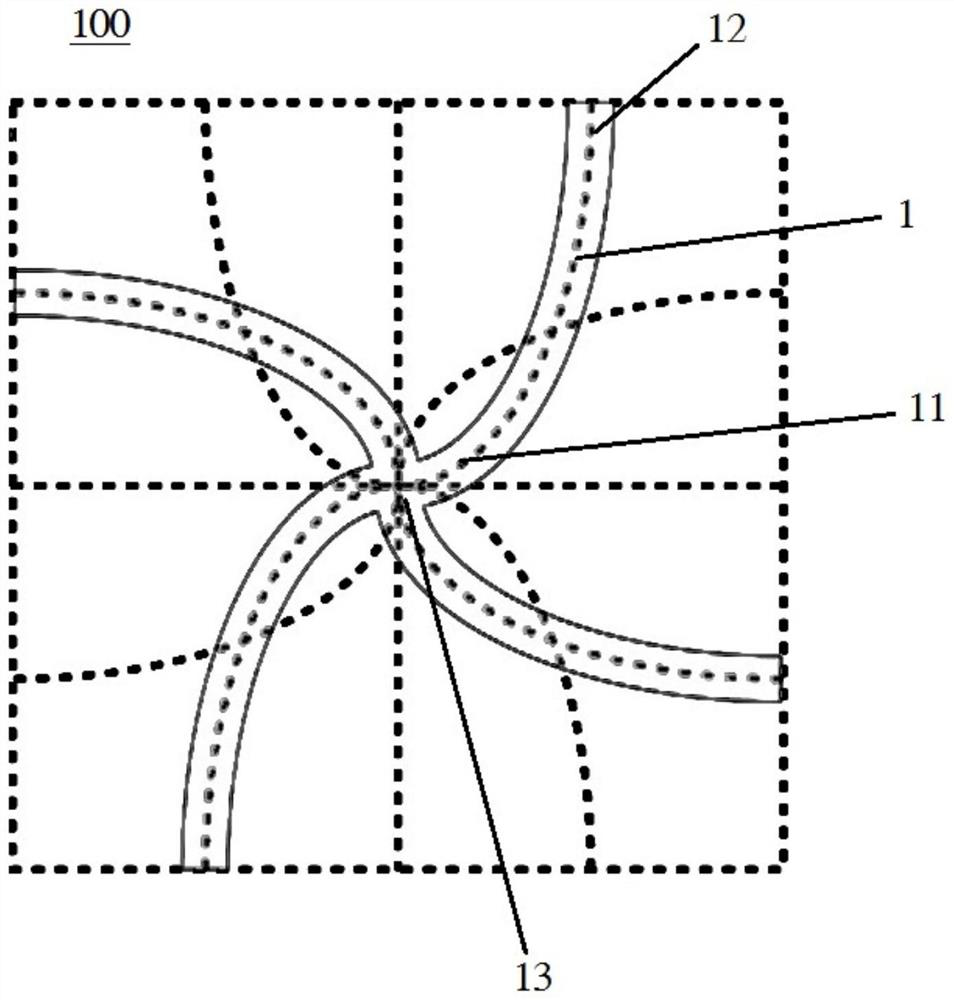

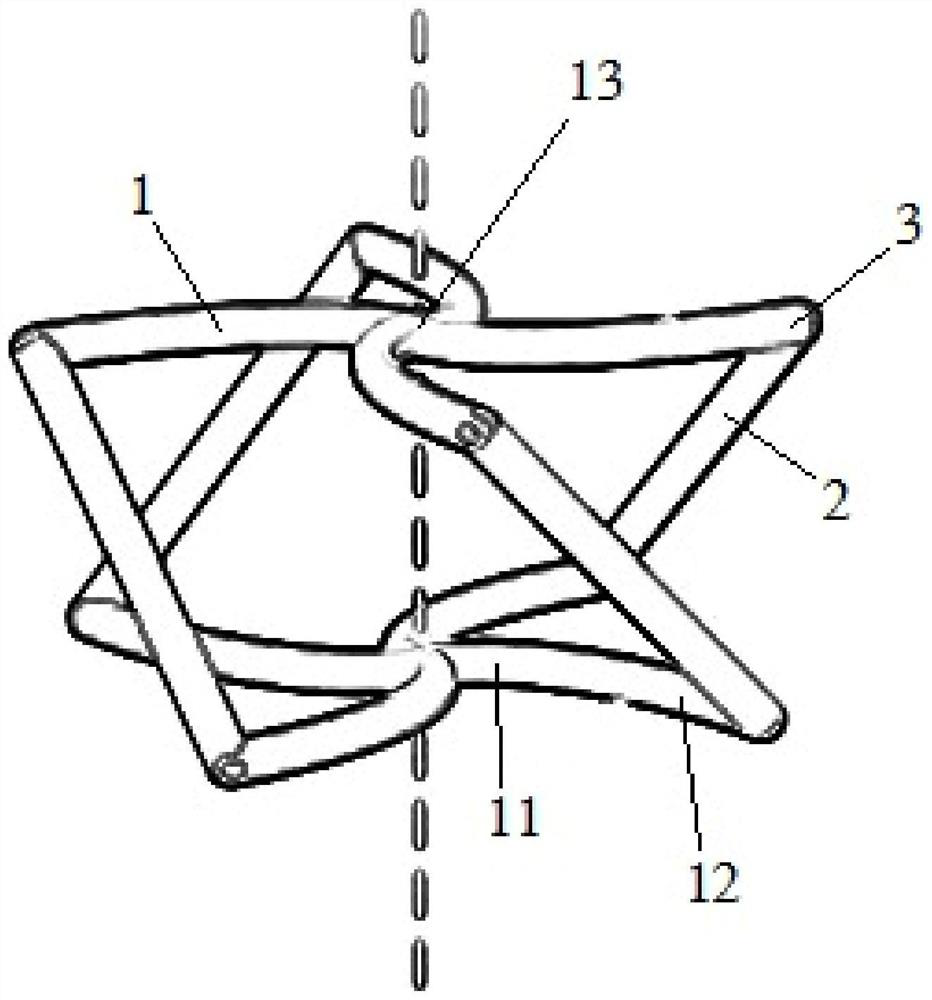

[0032] Example 2, see Figure 7 d- Figure 7 f, the number of helical arms 1 of each said helical unit 100 is four, the planar helical structure takes the inner end 11 of the helical arm 1 as the center of rotation, and the helical arm 1 takes 90° as the step-length circular array 4 times to obtain the helical unit 100 , the two adjacent spiral units 100 on the X-axis, Y-axis and Z-axis (up and down) are mirror images, and the upper and lower adjacent spiral units 100 are connected by four inclined rods 2, and the upper and lower ends of the inclined rods 2 are respectively connected to the spiral The outer ends 12 of the unit 100 are connected.

Embodiment 3

[0033] Example 3, see Figure 7 g- Figure 7 i, the number of helical arms 1 of each said helical unit 100 is six, the planar helical structure takes the inner end 11 of the helical arm 1 as the center of rotation, and the helical arm 1 takes 60° as the step size circular array 6 times to obtain the helical unit 100 , the two adjacent spiral units 100 on the X-axis, Y-axis and Z-axis (up and down) are mirror images, and the upper and lower adjacent spiral units 100 are connected by six inclined rods 2, and the upper and lower ends of the inclined rods 2 are respectively connected to the spiral The outer ends 12 of the unit 100 are connected.

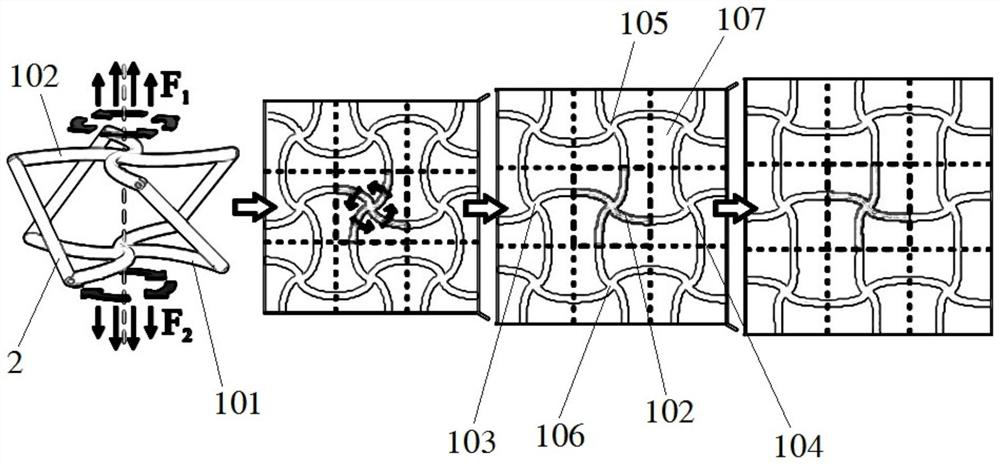

[0034] Taking Embodiment 2 as an example, when a reverse load is applied to the screw unit 100 in the Z-axis direction (pull the upper screw unit 102 upward, and pull the lower screw unit 101 downward), for example, please refer to image 3, the lower screw unit 101 below the tilt rod 2 rotates clockwise, and the upper screw unit 102 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com