Slitting machine

A technology of slitting machine and frame, which is applied in metal processing, winding strips, sending objects, etc. It can solve the problems of long replacement time, affecting production efficiency, cumbersome operation of changing wide coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

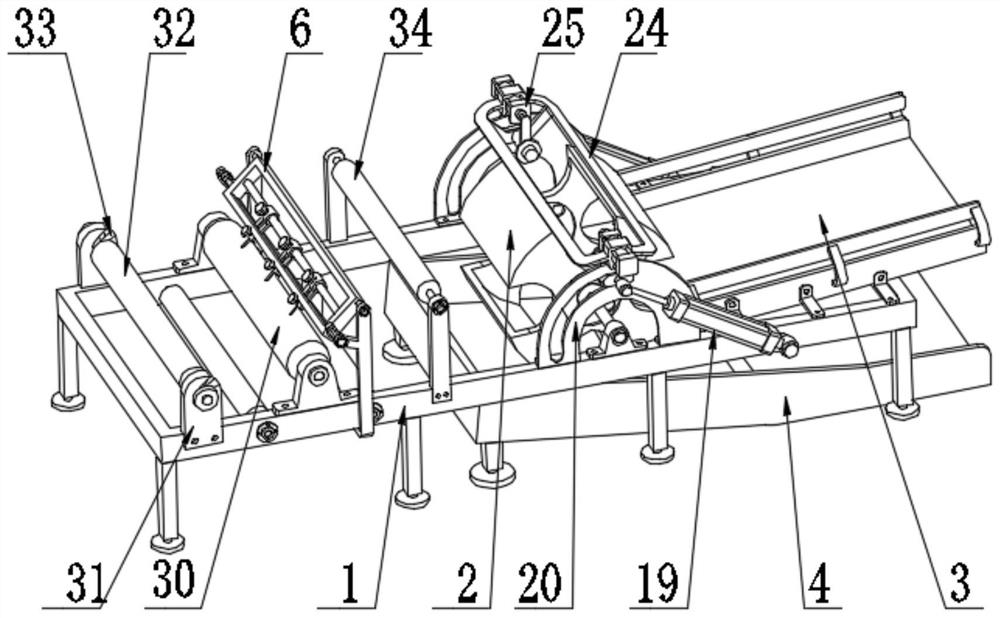

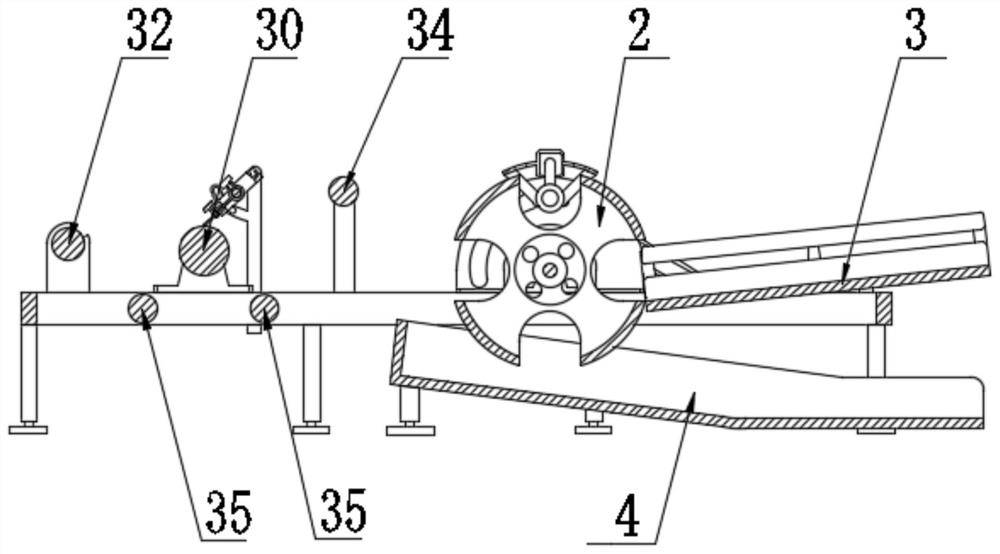

[0036] A kind of cutting machine of present embodiment, refer to Figure 1-8 : including a frame 1, the frame 1 is a rectangular frame structure, and the frame 1 is erected on the ground through the legs at the bottom;

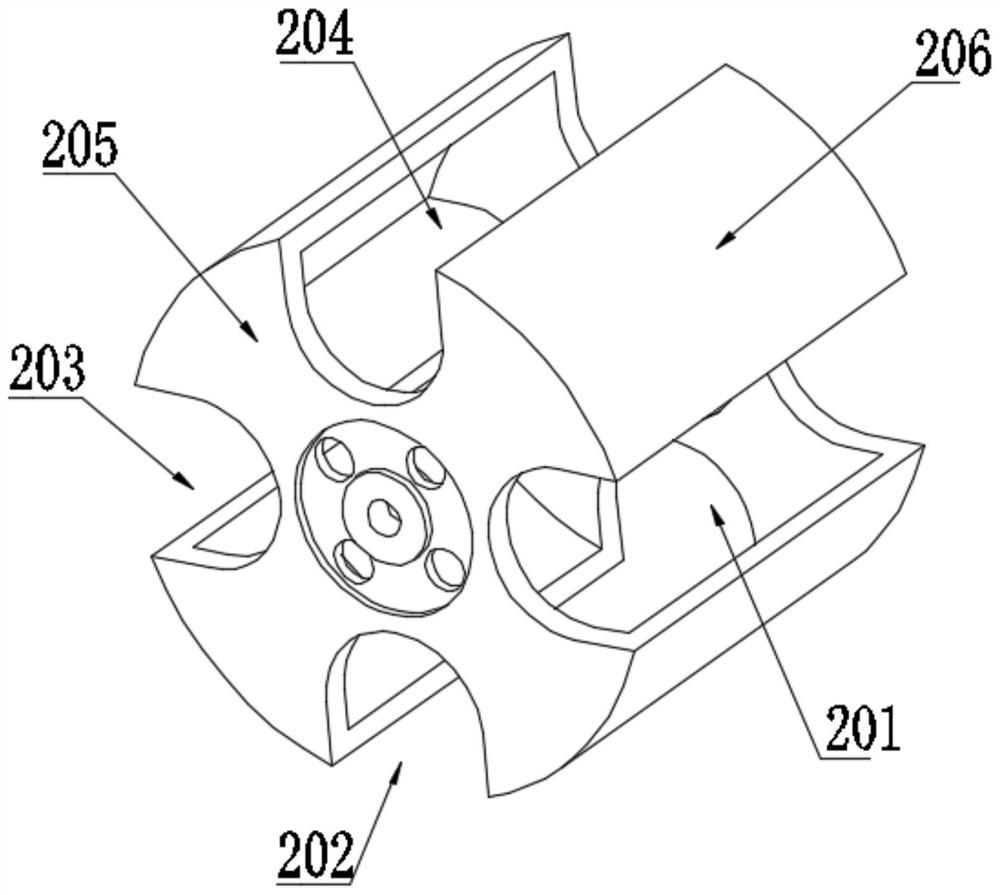

[0037] The top side of the frame 1 is rotatably connected with a transfer part 2 for transferring wide coils and barrels, and the transfer part 2 is provided with a coiling station 201, a feeding barrel station 202, and an unwinding station 203 in a clockwise direction. And the clamping station 204;

[0038] Specifically, the winding station 201, the unloading cylinder station 202, the unwinding station 203 and the clamping station 204 respectively correspond to different orientations of the transfer part 2, and are not fixed at a certain position of the transfer part 2, and The coiling station 201, the unloading cylinder station 202, the unwinding station 203 and the clamping station 204 have and can only put one set of wide-width coils, so as to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com