Constant-speed winding device for optical fiber manufacturing

A winding device and optical fiber technology, which is applied in the field of optical fiber manufacturing, can solve problems affecting production efficiency, economic loss, and fiber breakage, and achieve the effects of improving efficiency, avoiding economic loss, and ensuring uniform winding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

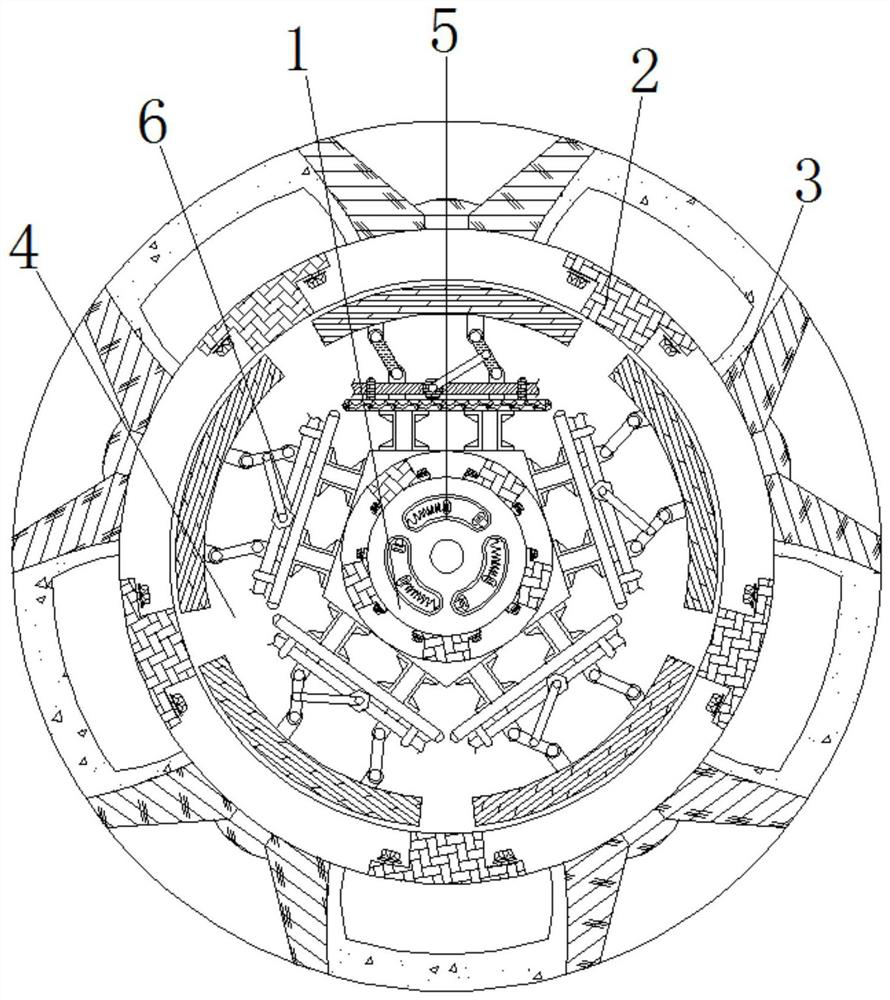

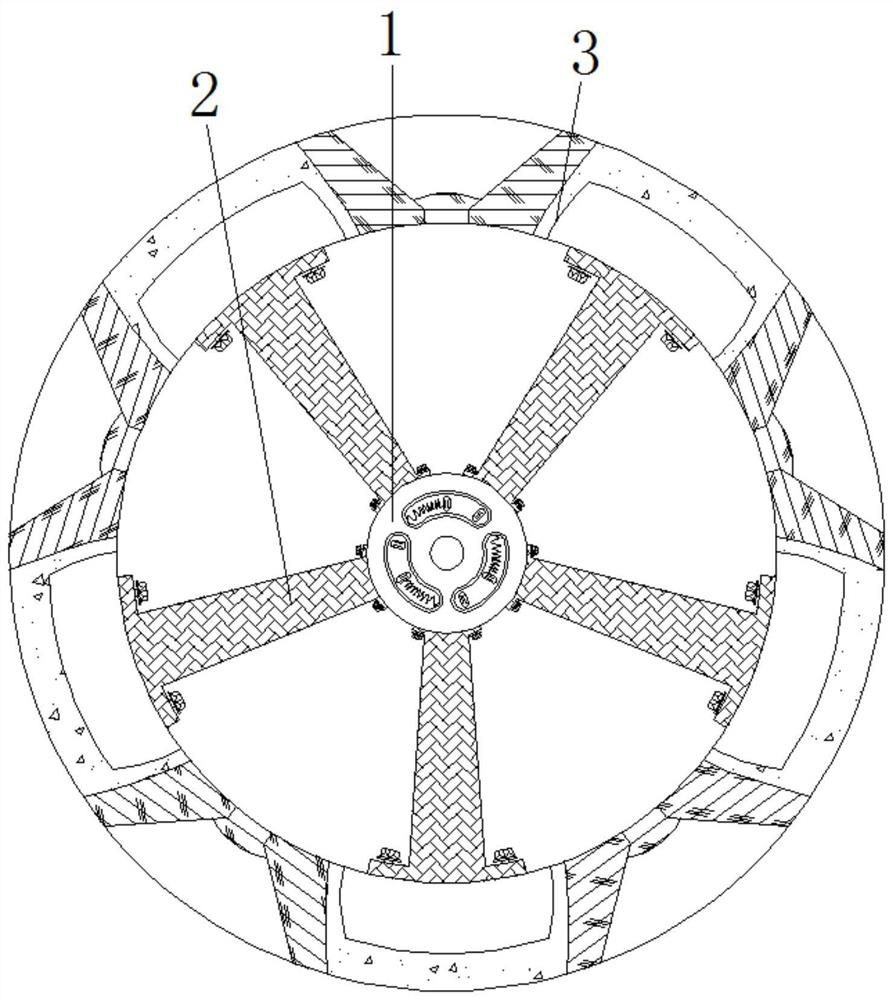

[0024] see figure 1 , figure 2 , Figure 4 , a constant speed winding device for optical fiber manufacturing, comprising a drive disc 1, a connection plate 2 is welded on the outside of the drive disc 1, a locking disc 3 is welded on the outside of the connection plate 2, and a device disc 4 is connected to the front of the drive disc 1 for rotation , the centers of the driving disc 1, the locking disc 3 and the device disc 4 are on the same straight line, and there are five connecting plates 2, which are evenly distributed with the center of the driving disc 1 as the center, and are respectively welded on the periphery of the driving disc 1;

[0025] The diameter of the locking disc 3 is larger than that of the driving disc 1, and the shape of the locking disc 3 is a ring, and five connecting plates 2 are welded between the locking disc 3 and the driving disc 1; the device disc 4 is rotatably connected to the driving disc 1, and the diameter of the device disk 4 is smaller...

Embodiment 2

[0028] see figure 1 , figure 2 , image 3 , a constant speed winding device for optical fiber manufacturing, comprising a drive disc 1, characterized in that: the outer side of the drive disc 1 is welded with a connecting plate 2, the outer side of the connecting plate 2 is welded with a locking disc 3, and the front of the drive disc 1 is rotationally connected There is a device disk 4, a trigger mechanism 5 is provided on the front of the drive disk 1, and a locking mechanism 6 is provided on the front of the device disk 4;

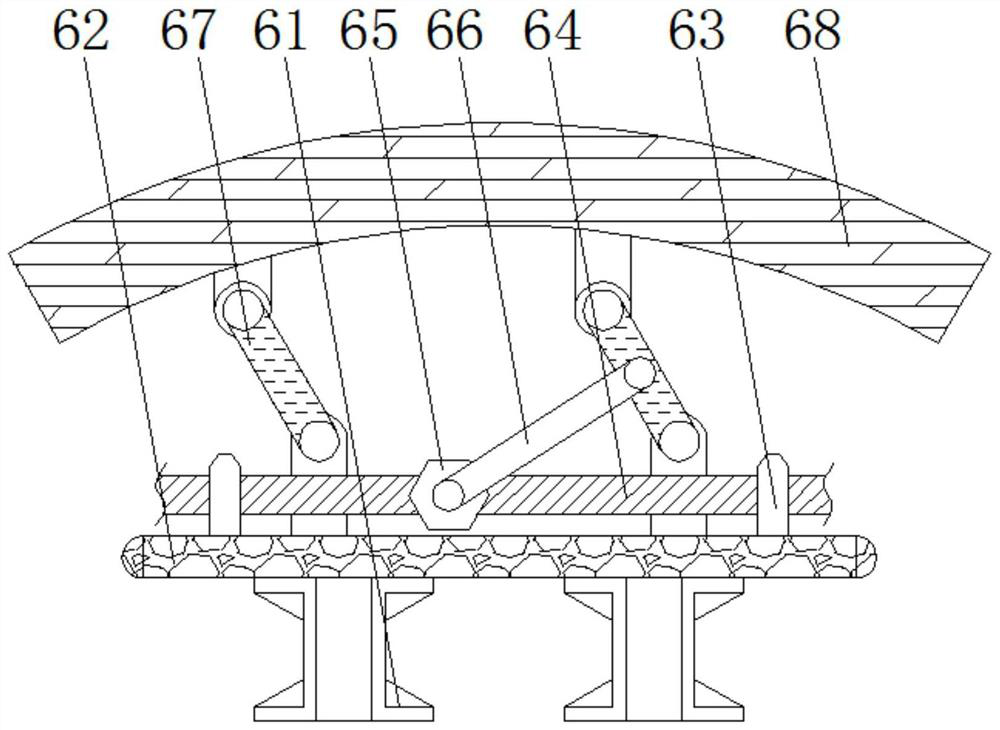

[0029] The locking mechanism 6 comprises a base 61, the top of the base 61 is welded with a device plate 62, the top of the device plate 62 is welded with a limit sleeve 63, the inside of the limit sleeve 63 is connected with a drive shaft 64 for rotation, and the lock mechanism 6 is provided with Five groups with the same internal structure and specifications, five groups of locking mechanisms 6 are evenly distributed around the center of the device...

Embodiment 3

[0033] see Figure 1-4 , a constant speed winding device for optical fiber manufacturing, comprising a drive disc 1, characterized in that: the outer side of the drive disc 1 is welded with a connecting plate 2, the outer side of the connecting plate 2 is welded with a locking disc 3, and the front of the drive disc 1 is rotationally connected There is a device plate 4, the centers of the drive plate 1, the lock plate 3 and the device plate 4 are on the same straight line, and there are five connecting plates 2, which are evenly distributed around the center of the drive plate 1 and welded to the drive plate 1 respectively. the periphery;

[0034] The diameter of the locking disc 3 is larger than that of the driving disc 1, and the shape of the locking disc 3 is a ring, and five connecting plates 2 are welded between the locking disc 3 and the driving disc 1; the device disc 4 is rotatably connected to the driving disc 1, and the diameter of the device disk 4 is smaller than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com