Antibacterial glass product and preparation method thereof

A technology for antibacterial glass and glass products, applied in the field of glass products, can solve the problems of high process cost, time-consuming and high cost, and achieve the effects of simple and easy operation, low cost and few raw materials in the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

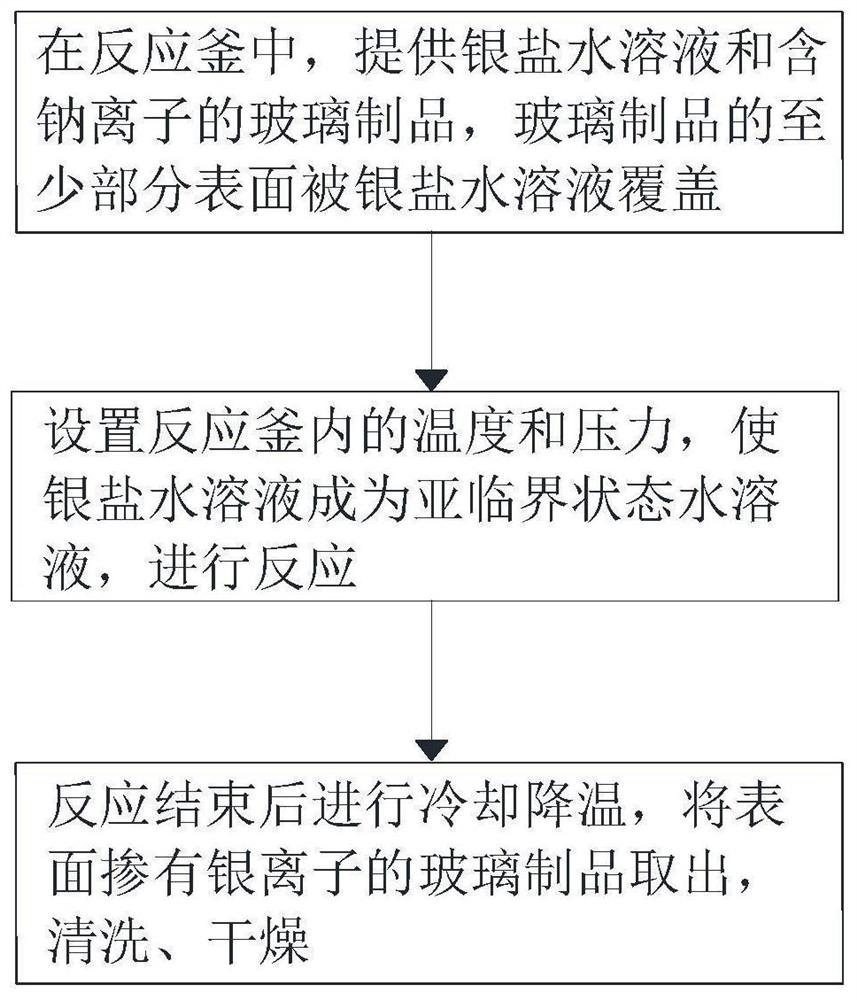

[0039] This specific embodiment provides a kind of preparation method of antibacterial glass product, comprises the following steps:

[0040] S1: Prepare 500ppm (0.05wt%) silver nitrate aqueous solution and place it in a reaction kettle; clean the borosilicate glassware, soak the borosilicate glassware in the silver nitrate aqueous solution, the borosilicate glassware Both the inner and outer surfaces were immersed in the silver nitrate aqueous solution.

[0041] S2: Set the temperature in the reactor to 110°C-200°C. Correspondingly, the specific system pressure can be obtained by setting the temperature; make the silver nitrate aqueous solution into a subcritical state aqueous solution, and maintain the temperature for reaction for 60 minutes.

[0042] S3: After the reaction is completed, the temperature is lowered, and the borosilicate glass vessel doped with silver ions on the surface is taken out, ultrasonically cleaned, and vacuum-dried in an oven for 10-60 minutes.

[0...

Embodiment 1

[0045] Embodiment 1 prepares the silver nitrate aqueous solution of 500ppm, puts the silver nitrate aqueous solution in the reaction kettle; cleans the borosilicate glassware, soaks the borosilicate glassware in the silver nitrate aqueous solution, the inner surface of the glassware and The outer surfaces were all immersed in the silver nitrate aqueous solution. The temperature in the reactor was set at 110° C. to make the silver nitrate aqueous solution into a subcritical aqueous solution, and the temperature was maintained for 60 minutes to carry out the reaction. Cool down after the reaction, take out the borosilicate glass vessel doped with silver ions on the surface, clean it with ultrasonic waves, and dry it in a vacuum oven for 30 minutes.

Embodiment 2

[0046] The difference between Example 2 and Example 1 is that the temperature in the reactor is set to 125°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com