Salt-tolerant lactobacillus fermentum for improving flavor quality of fermented soy sauce and application of salt-tolerant lactobacillus fermentum

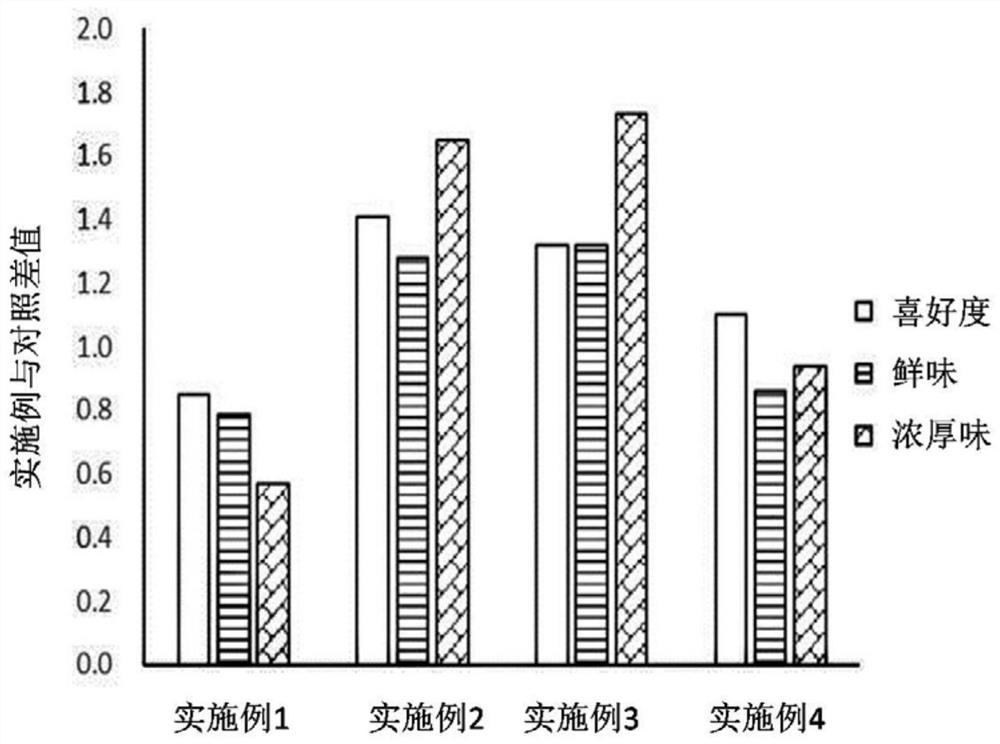

A technology for fermenting Lactobacillus and brewing soy sauce, which is applied in the field of food microbiological technology application, to achieve the effect of optimizing the umami and thick taste of soy sauce, enhancing the aroma of ester and sauce, and coordinating and lasting the flavor of soy sauce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Soaking beans and cooking: select soybeans (soybeans) with full graininess, add them into clear water, the mass ratio of the soybeans to clear water is 1:2.2, soak them in clear water for 8 hours, and finish under high temperature and high pressure after soaking fully Cooking, control the cooking pressure at 0.11MPa, the cooking time is 13min, the cooking temperature is 125°C, filter and take the filter residue to obtain cooked beans;

[0058] (2) Mixing materials and mixing koji: Cool the cooked beans obtained in step (1) to 40°C, mix in flour koji essence and mix evenly. Calculated according to dry weight, the mass ratio of flour to soybeans is 1:4; the used The koji essence is Aspergillus oryzae, and according to the dry weight, the inoculum amount of the koji essence is controlled at 0.05wt% of the total weight of soybeans and flour, and the three are evenly mixed to obtain Daqu.

[0059] (3) Cultivation of Daqu: The Daqu obtained in step (2) was subjected to so...

Embodiment 2

[0067] (1) Soaking beans and steaming: select soybeans (soybeans) with full graininess, add them into clear water, the mass ratio of the soybeans to clear water is 1:2.5, soak them in clear water for 6 hours, and finish under high temperature and high pressure after soaking fully Cooking, control the cooking pressure at 0.1MPa, the cooking time at 15min, and the cooking temperature at 123°C, filter and take the filter residue to obtain cooked beans;

[0068] (2) Mixing materials and mixing koji: cool the cooked beans obtained in step (1) to 32°C, mix in flour and koji essence, and mix evenly. Calculated according to dry weight, the mass ratio of flour to soybeans is 1:3, so The koji essence used is Aspergillus oryzae. According to the dry weight, the inoculum amount of the koji essence is controlled at 0.04wt% of the total weight of soybean and flour, and the three are evenly mixed to obtain Daqu.

[0069] (3) Cultivation of Daqu: The Daqu obtained in step (2) was solid-state ...

Embodiment 3

[0077] (1) Soaking beans and cooking: select soybeans (soybeans) with full graininess, add them into clear water, the mass ratio of the soybeans to clear water is 1:2.3, soak in clear water for 10 hours, and finish under high temperature and high pressure after soaking fully Cooking, adjust the cooking pressure at 0.12MPa, the cooking time is 10min, the cooking temperature is 121°C, filter and take the filter residue to obtain cooked beans;

[0078] (2) Mixing materials and mixing koji: Cool the cooked beans obtained in step (1) to 45°C, mix in flour koji essence and mix raw materials. Calculated according to dry weight, the mass ratio of flour to soybeans is 1:5. The koji essence is Aspergillus oryzae. According to the dry weight, the inoculum amount of the koji essence is controlled at 0.06wt% of the total weight of soybeans and flour, and the three are evenly mixed to obtain Daqu.

[0079] (3) Cultivation of Daqu: the Daqu obtained in step (2) was solid-state fermented, fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com