Main cable internally-penetrating assembly type steel cross beam of vehicle cableway bridge

A technology of assembled and steel beams, which is applied in bridges, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment is applicable to the structure of the in-line steel beam. Taking a cableway bridge with a main span of 438m as a design example, the design load is -80 for cars and -80 for hanging.

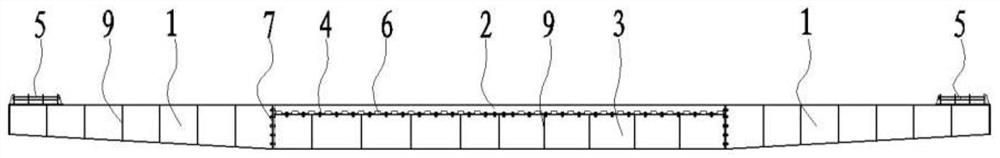

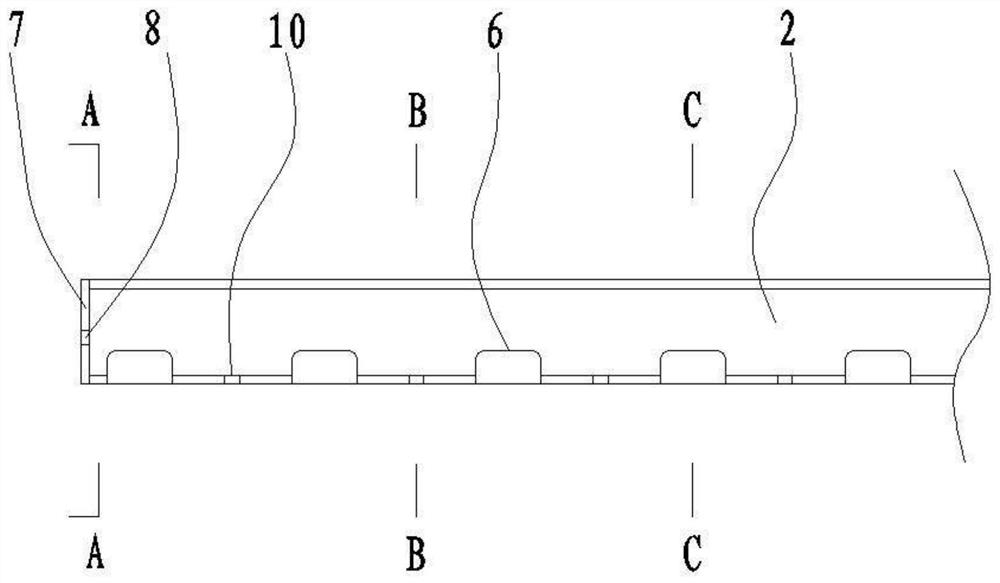

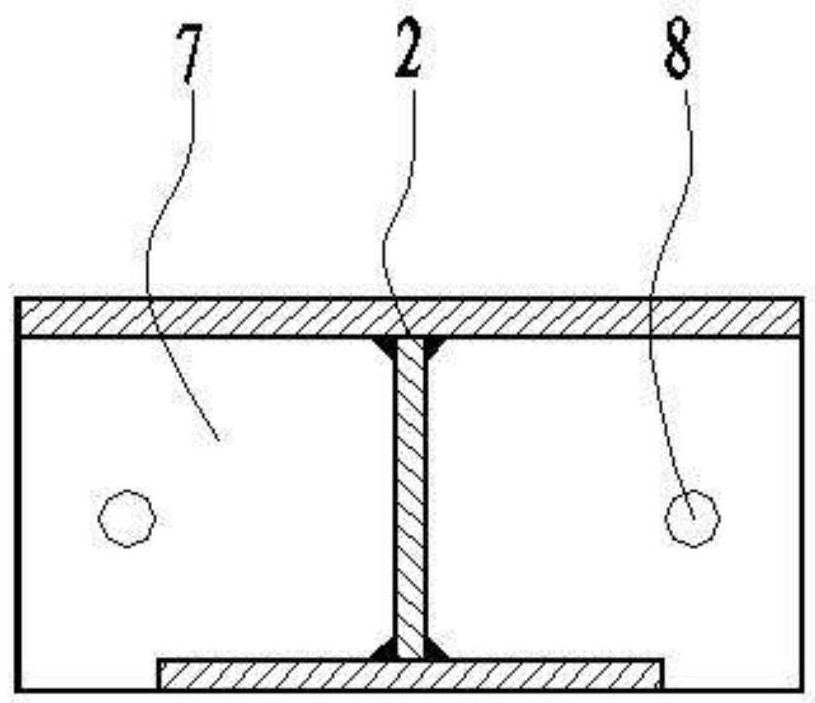

[0045] Such as Figure 1 to Figure 13As shown, this embodiment includes two beam side segments 1 and a middle section between the two beam side segments 1, and the lengths of the beam side segments 1-middle section-beam side segment 1 are sequentially For, 3520mm, 6000mm and 3520mm. The middle section includes the upper section 2 of the middle section of the beam and the lower section 3 of the middle section of the beam with the same length. The upper section 2 of the middle section of the beam and the lower section 3 of the middle section of the beam are stacked up and down. The lengths of the upper section 2 of the middle section and the lower section 3 of the middle section of the crossbeam are both 6000 mm, that is, the length ratio of the side section 1 of the crossb...

Embodiment 2

[0053] This embodiment is applicable to the structure of inverted figure-eight steel beams. Taking a cableway bridge with a main span of 438m as a design example, the design load is -80 for cars and -80 for hanging.

[0054] Specifically, on the basis of Embodiment 1, according to the design requirements, the upper flange plate of the beam side section 1 in this embodiment is further tilted upward, so that the end section of the beam forms a symmetrical inverted eight in the cross section of the bridge. glyph structure. At the same time, some adaptive adjustments are made to the structure of the web of the beam side segment 1 and the structure of the roller assembly 5 .

[0055] The beneficial effect of the present invention is that the bridge deck cables pass through the steel beam web, not only can omit the special bridge deck for the beam of the traditional cableway bridge, but also adopt the traditional beam installation method of the cableway bridge to install the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com